Container with internal pattern adjustment

A technology for packaging and containers, which is applied in the field of packaging containers with internal pattern adjustment, can solve the problems of non-adjustable cavity volume, waste of storage space, and high storage costs, so as to improve utilization rate, avoid waste, and prevent materials from being mixed and unusable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

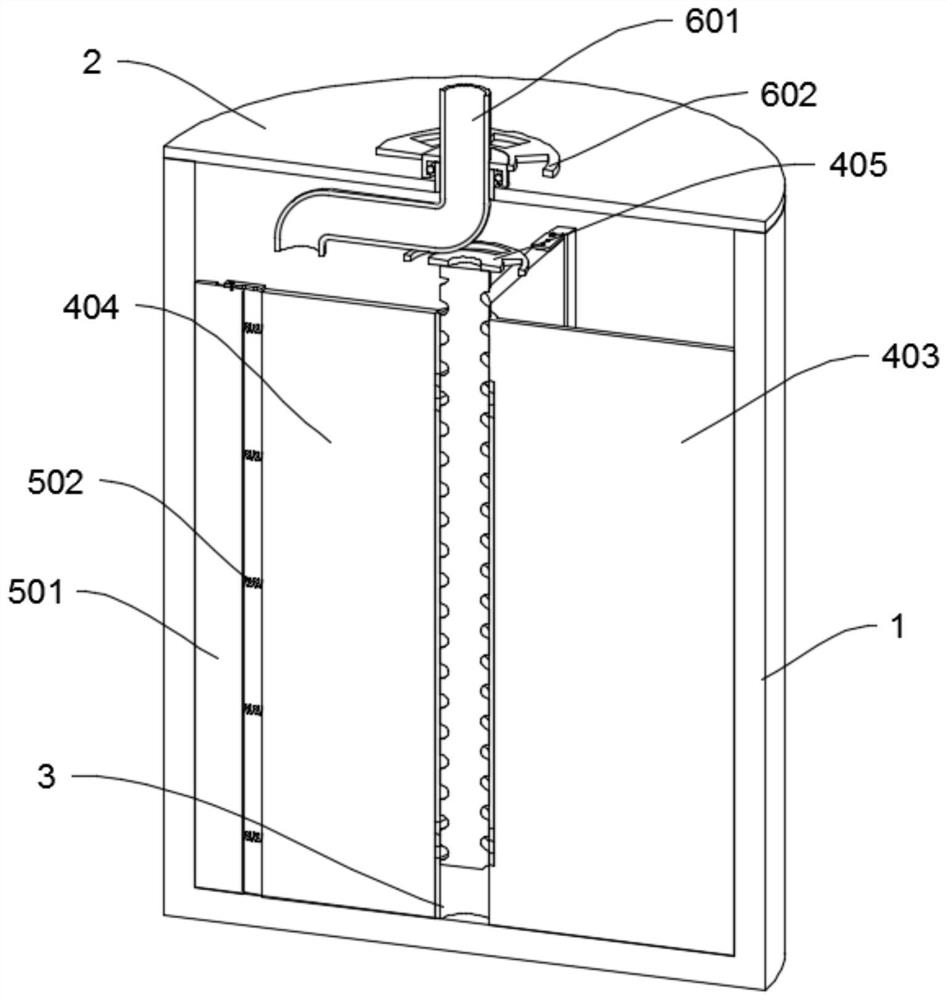

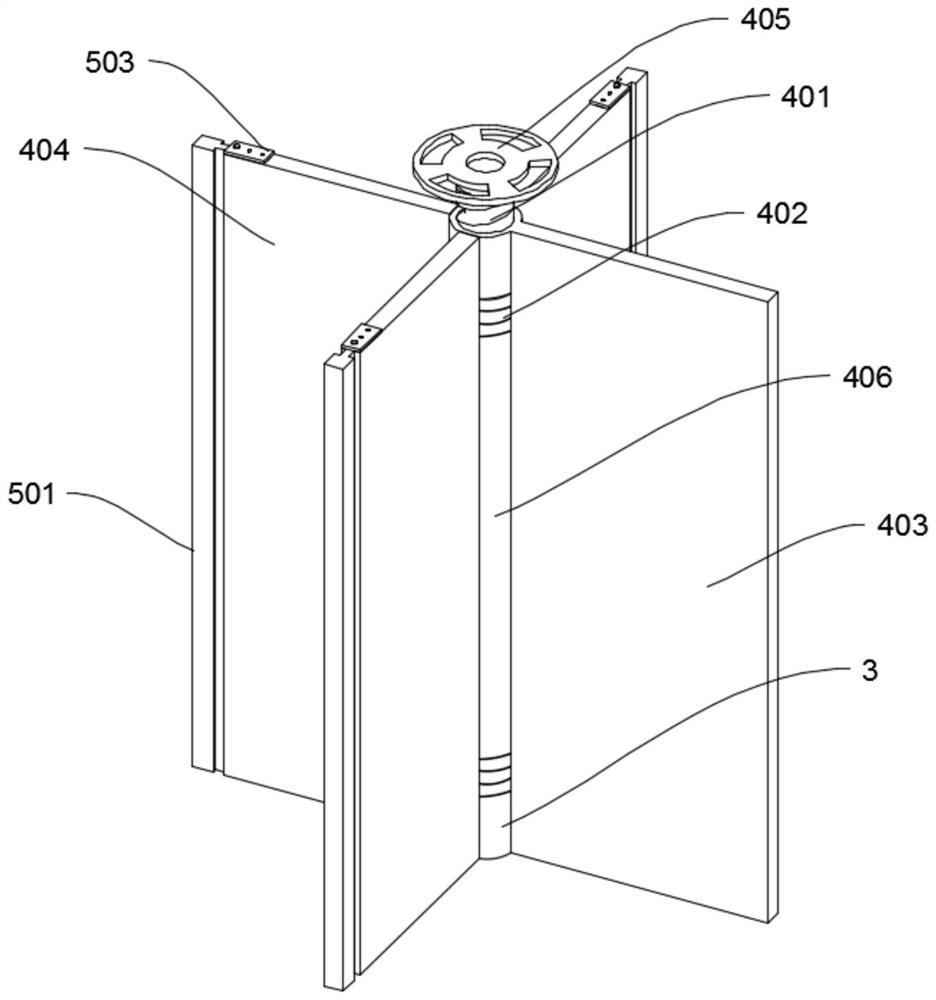

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

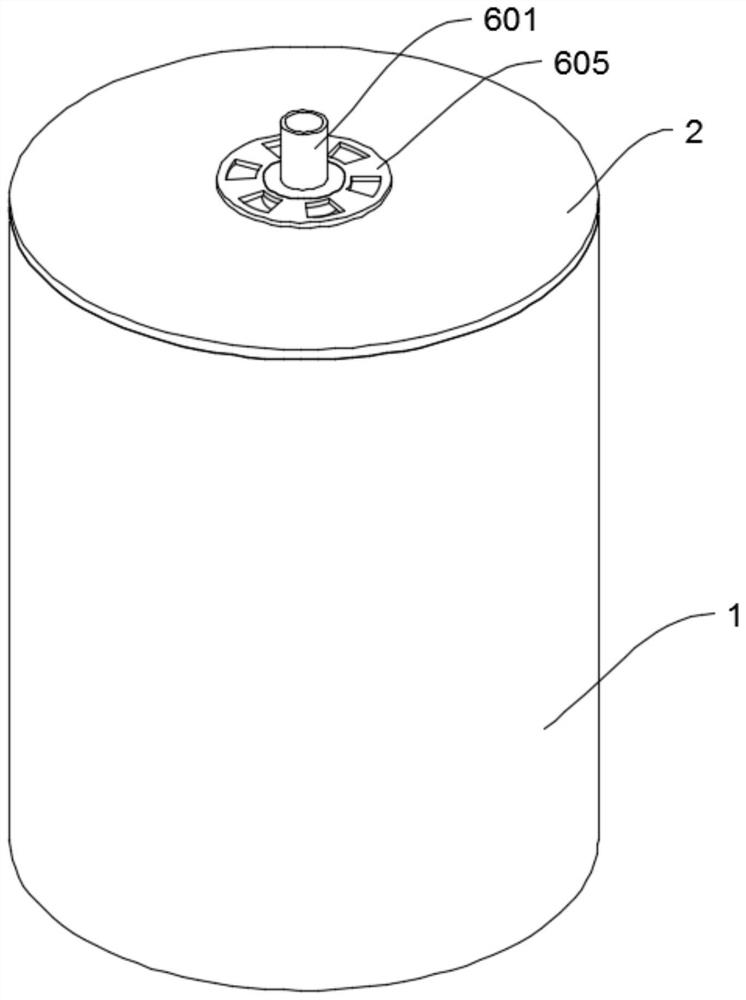

[0027] refer to Figure 1-8 As shown, a container with internal pattern adjustment includes a container body 1 , a rotating mechanism 4 , a sealing mechanism 5 and a feeding mechanism 6 .

[0028] In the specific implementation process, refer to image 3 and Figure 4 As shown, the container body 1 is provided with a tank cover 2 and a limit seat 3, and a rotating mechanism 4 for adjusting the space and isolating materials for the container body 1 is arranged in the container body 1 for sealing and isolating. The mechanism 5 is arranged in the container tank body 1, and the sealing mechanism 5 and the sealing mechanism 5 rotating mechanism 4, the feeding mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com