Sludge curing agent and application thereof

A curing agent and sludge technology, which is applied in the field of curing chemicals, can solve the problems of large proportion of foreign materials, difficulty in dehydrating sludge, and low strength of consolidated bodies, so as to eliminate adverse effects, reduce road construction costs, Good board performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 gets each raw material component of sludge curing agent by following weight ratio:

[0024] The powder raw materials are: ordinary portland cement clinker 45kg, active slag 40kg, slaked lime 5kg, gypsum 5kg, sodium sulfate 5kg;

[0025] The raw materials of the liquid preparation are: 15 kg of polyacrylamide, 75 kg of calcium lignosulfonate, 2.0 kg of alkylphenol polyoxyethylene ether (OP-10), and 2.5 kg of α-olefin sulfonate.

[0026] The raw materials of the powder are ground into fine powders of about 200 meshes, mixed evenly, and the components of the liquid are mixed to obtain the powder and liquid of the sludge curing agent.

Embodiment 2

[0030] Embodiment 2 gets each raw material component of sludge solidifying agent by following weight ratio:

[0031] The powder raw materials are: Portland cement clinker 30kg, active slag 60kg, lime 4kg, gypsum 2kg, aluminum sulfate 4kg;

[0032] The raw material composition of the solution is: polyacrylamide 30kg, polyaluminum chloride 5kg, mannitol 5kg, sodium lignosulfonate 20kg, complex compound of sodium lignosulfonate and iron ion 30kg, alkylphenol polyoxyethylene ether (OP-7) 2.0kg, tannin 8kg, α-olefin sulfonate 0.2kg.

[0033] The powder raw materials of the above-mentioned sludge solidifying agent are pulverized and then mixed, and the raw materials of the liquid formulation are stirred and mixed evenly to obtain the sludge solidifying agent.

Embodiment 3

[0035] Embodiment 3 gets each raw material component of sludge curing agent by following weight ratio:

[0036] The powder raw materials are: Portland cement clinker 60kg, active slag 30kg, lime 3kg, gypsum 3kg, aluminum sulfate 4kg;

[0037] The raw material composition of liquid preparation is: polyacrylamide 5kg, polyaluminum chloride 10kg, mannitol 20kg, sodium lignosulfonate 60kg, alkylphenol polyoxyethylene ether (OP-15) 0.5kg, tannic acid 1.0kg, Sodium humate 2.0kg, α-olefin sulfonate 0.5kg.

[0038] The powder raw materials of the above-mentioned sludge solidifying agent are pulverized and then mixed, and the raw materials of the liquid formulation are stirred and mixed evenly to obtain the sludge solidifying agent.

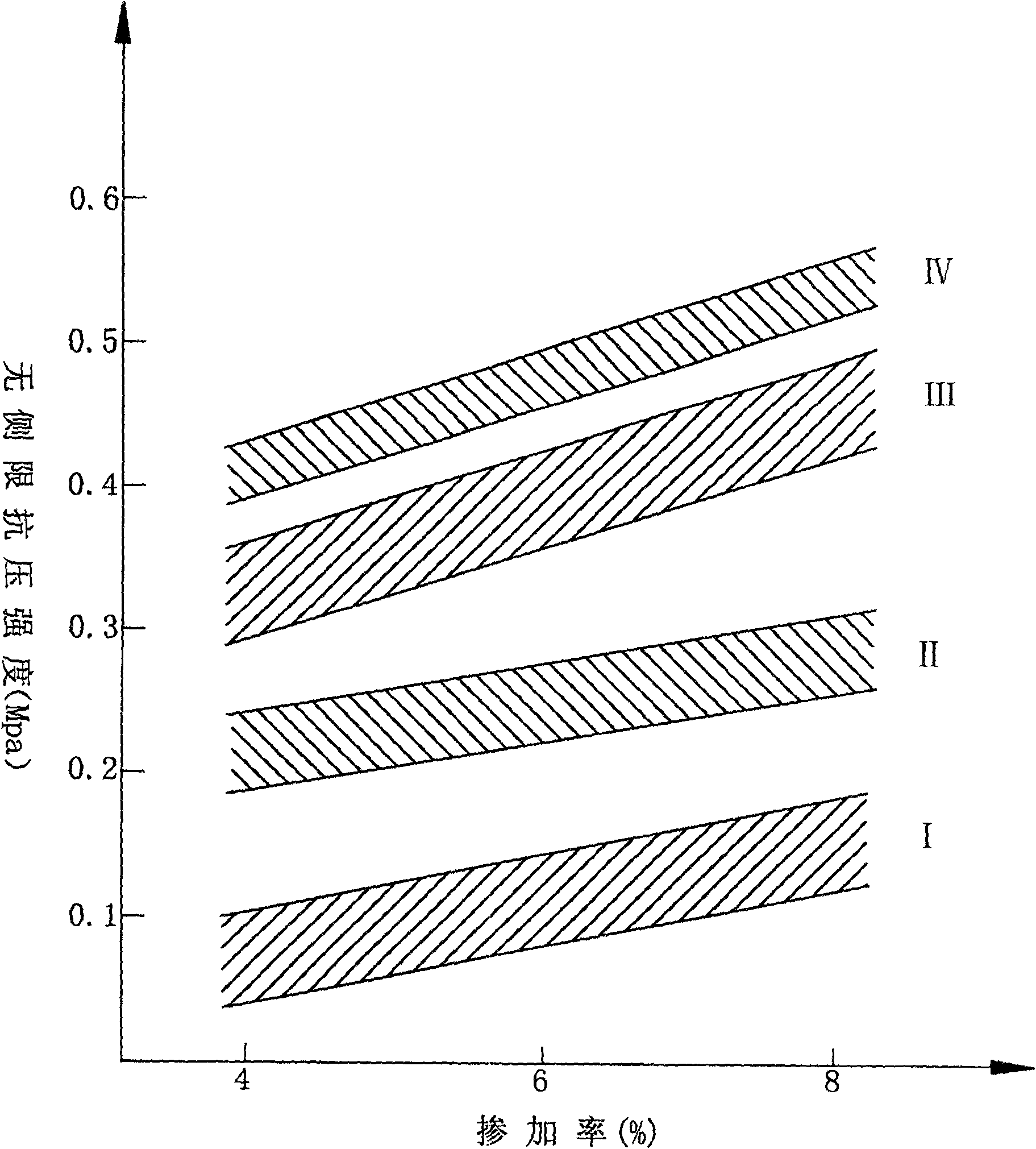

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com