Programmable gain amplifier

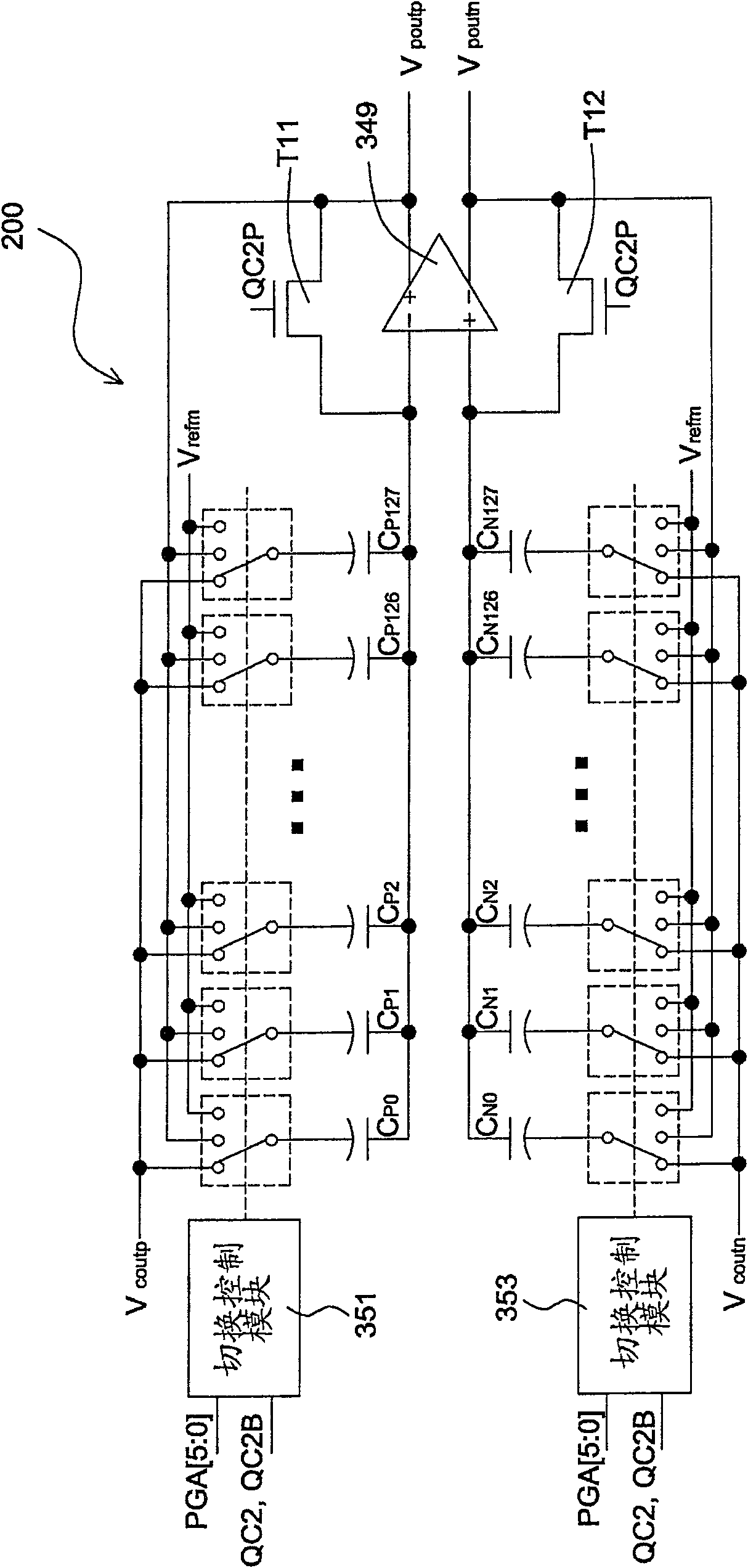

A programming gain and amplifier technology, applied in the direction of analog-to-digital converters, etc., can solve the problems of not being able to save the capacitor CF area, and cannot provide a variety of control mechanisms, so as to achieve the effect of saving the capacitor area and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The programmable gain amplifier of the present invention will be described in detail below with reference to the drawings.

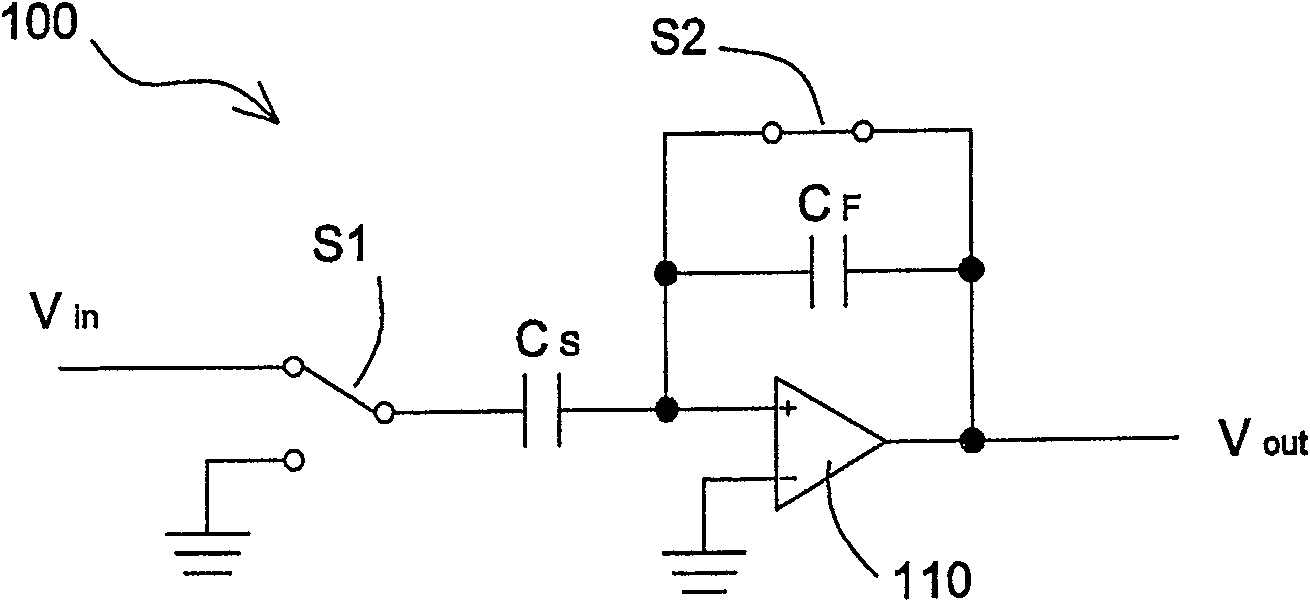

[0035] Figure 4A It is a schematic diagram of the first embodiment of the programmable gain amplifier 400 of the present invention. In this embodiment, the programmable gain amplifier 400 is a 4-bit programmable gain amplifier. The programmable gain amplifier 400 includes an operational amplifier 110, two groups (N+1 groups) of adjusting capacitor modules 402, 404, two groups (N+1 groups) of switch modules 406, 408, and a feedback switch S F , One (N) attenuation capacitor C SC , A feedback capacitor C F , And a control module 430. Where N is a positive integer greater than 0, and N is 1 in this embodiment.

[0036] Such as Figure 4A As shown, the first group of adjusting capacitor modules 402 includes capacitors C1 and C2 connected to the first end; the second group of adjusting capacitor modules 404 includes capacitors C3 and C4 connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com