Electric motor with brush holder and its assemblage method

一种组件、电刷装置的技术,应用在机电装置、电动组件、电路等方向,能够解决高速高功率电机不适用、电刷和换向器磨损、管道变形等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

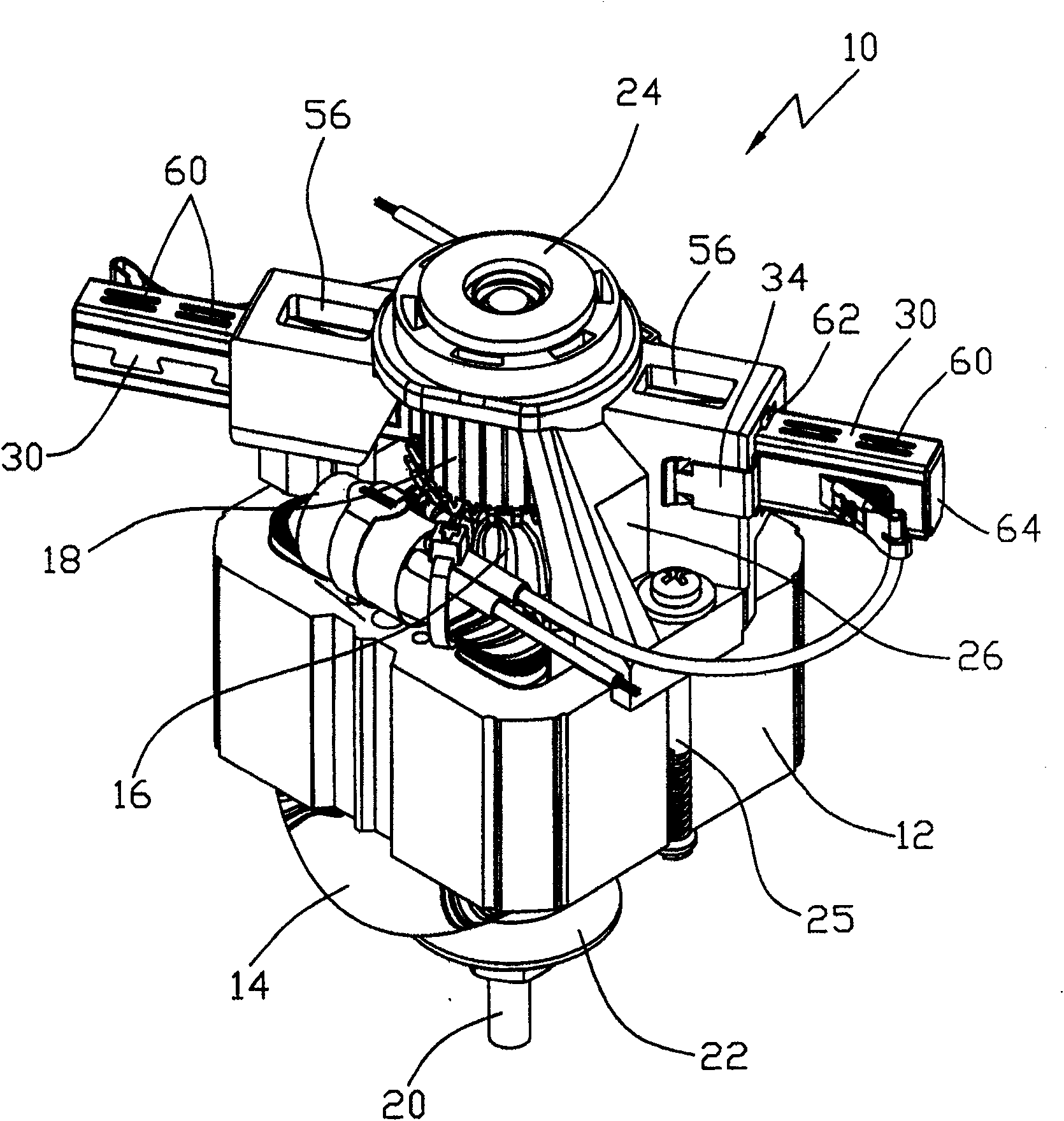

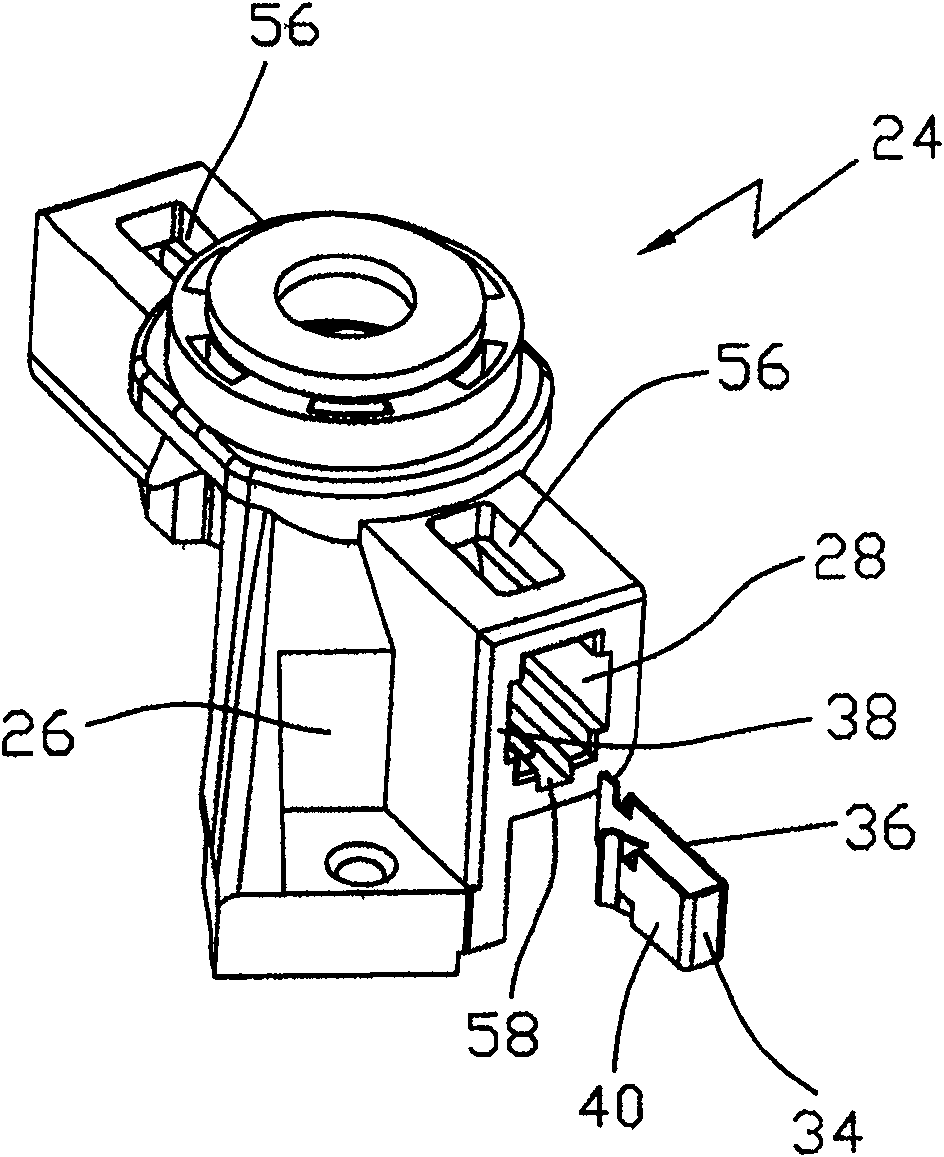

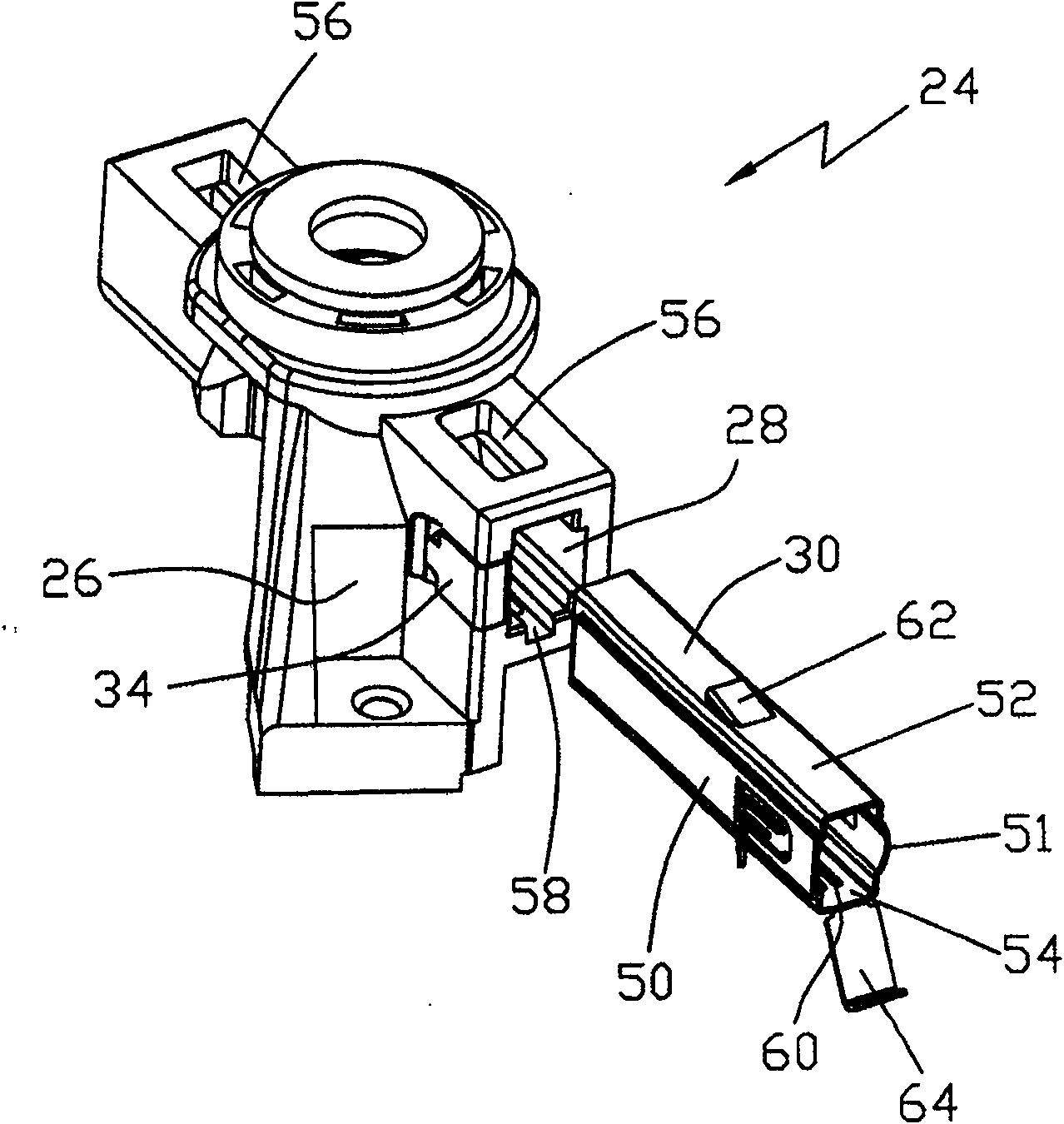

[0031] In the following, we will describe the figure 1 The invention is illustrated with reference to a preferred embodiment of a brush assembly for use in a general motor as shown. The general purpose electric machine 10 has a laminated stator core 12 supporting stator windings 14 . The wound rotor 16 includes a commutator 18 and a shaft 20 and is positioned extending through the stator core 12 . The output bearing housing 22 is fixed to one axial end of the stator core. The input bearing housing 24 is fixed to the other axial end of the stator core. The bearing blocks 22 , 24 are fixed to the stator core 12 by screws 25 , which here extend through the through holes of the bearing blocks 22 , 24 and pass through or flank the stator core 12 . Two bearing blocks 22, 24 support bearings in which the shaft 20 is journalled. The output bearing housing 22 is U-shaped and may include additional holes for mounting the motor to other equipment. The input bearing housing 24 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com