Construction for enhancing reliability of phase-change memory storage unit and manufacturing method thereof

A technology of phase-change memory and storage unit, which is applied in the direction of static memory, read-only memory, digital memory information, etc., and can solve problems that affect device performance and reliability, difficulty in distinguishing resistance values, and large contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

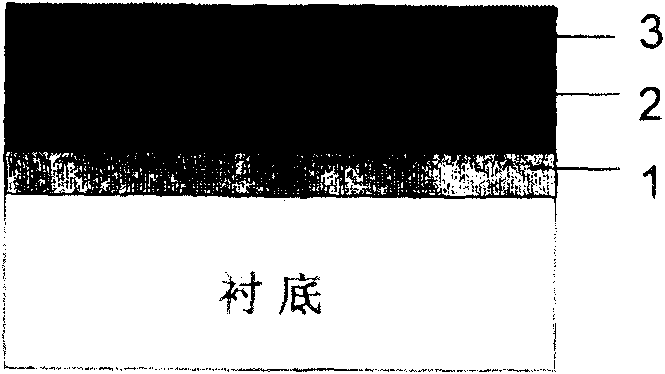

[0036] (1) Prepare a 200nm thick Al film on the substrate as the bottom electrode, and prepare a 350nm thick SiO on the bottom electrode Al film by electron beam evaporation 2 , in SiO 2 The nanoholes are prepared by electron beam etching method, the bottom of the hole is connected with the bottom electrode, the diameter of the hole is 200nm, and the W film is deposited in the hole by PVD technology until the hole is filled;

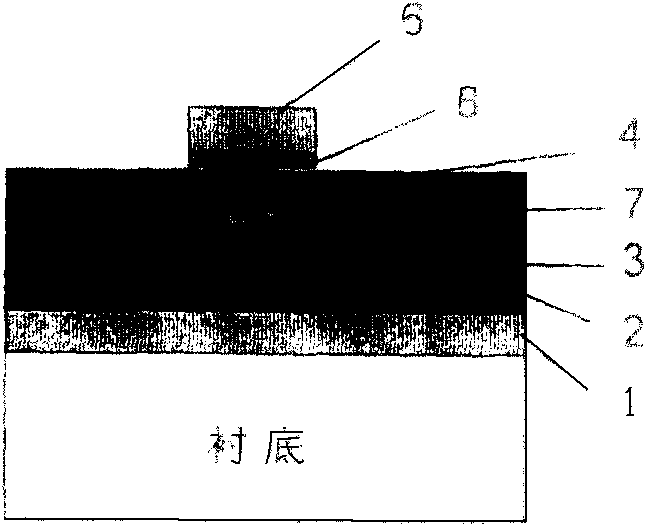

[0037] (2) Use CMP technology to throw away W in the area outside the pores to form SiO 2 A structure in which a columnar W heating electrode is embedded in the medium; ( figure 2 )

[0038] (3) Using W and SiO 2 Different etching rates of the medium, using RIE to etch the top of the W heating electrode to 200nm, thereby forming a dielectric hole at the top of the W heating electrode; ( image 3 )

[0039] (4) Use ALD technology to fill the buffer material TiN in the dielectric hole at the top of the W heating electrode, and polish the TiN outside ...

Embodiment 2

[0045] Replace the heating electrode W in Example 1 with WTiN, prepare a columnar WTiN in the dielectric hole in the first step of Example 1 as the heating electrode, and then etch a part of the top of the WTiN to form a dielectric hole, and then fill the phase change material. Other follow-up The process steps are the same as in Example 1, and similar properties can be obtained, but the process steps are more simplified.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com