Multi-parameter sensor for measuring differential pressure/pressure/temperature

A differential pressure sensor, detection sensor technology, applied in the pressure difference measurement between multiple valves, elastic deformation meter type fluid pressure measurement, fluid pressure measurement using capacitance changes, etc., can solve the difficult detection of various parameters, etc. problem, to achieve the effect of light weight, good development space, small and exquisite appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

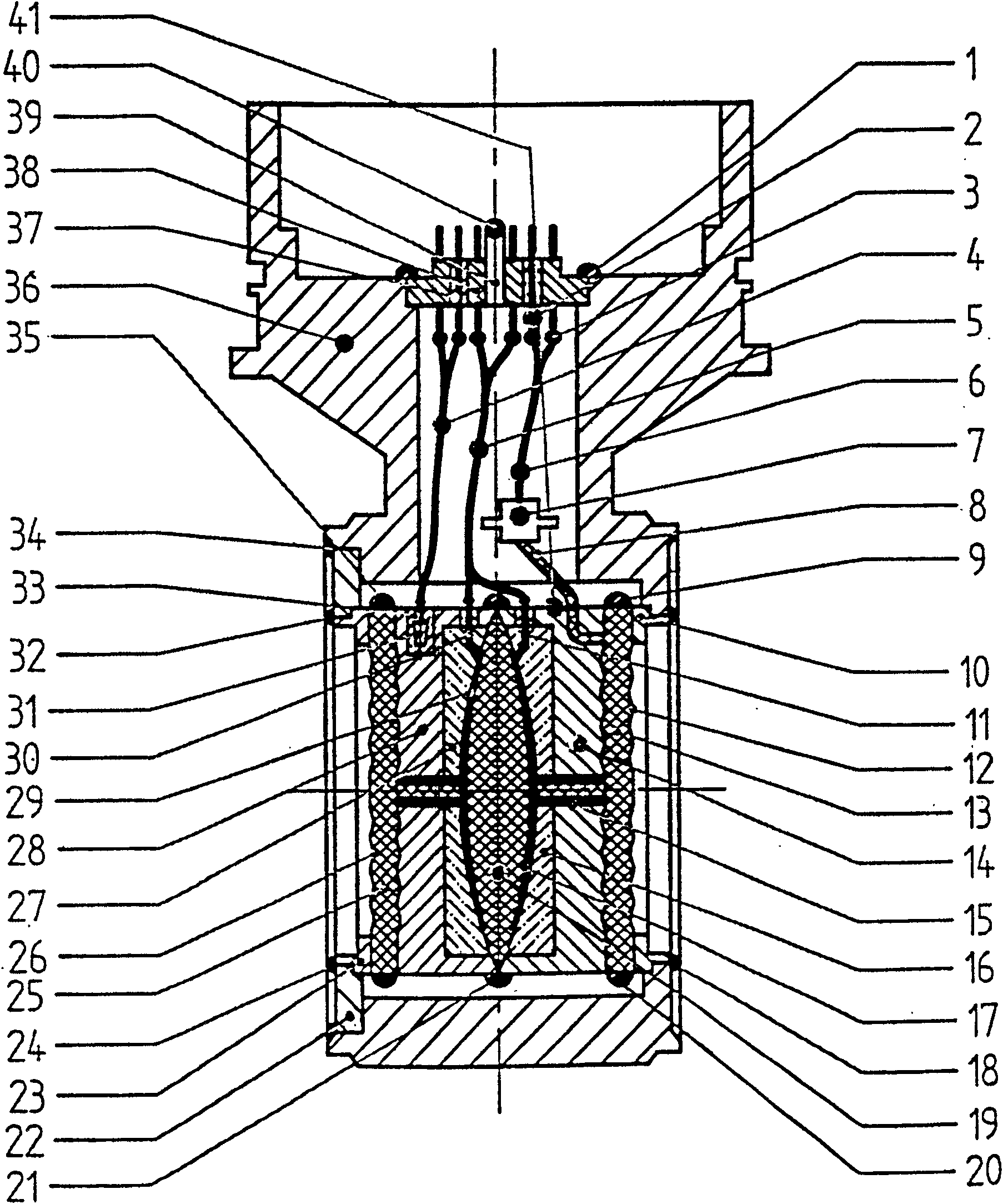

[0015] A multi-parameter sensor for simultaneous measurement of differential pressure, pressure and temperature, composed of figure 1 As shown, it is characterized in that a differential capacitance bellows type differential pressure sensor 41 for detecting differential pressure signals is packaged in combination in the housing 36; a piezoresistive static pressure sensor 7 for detecting static pressure signals and the detection sensor itself and A high-precision integrated temperature measurement chip 31 with digital output of the temperature of the medium in contact with it, and three sensors are used to detect various parameters of differential pressure, pressure and temperature. The above-mentioned differential capacitance capsule-type differential pressure sensor is placed in the lower circular cavity of the housing 36, which consists of two circular metal bases 14, 28 and a circular elastic metal pressure-sensitive diaphragm 19 Welding rings (welding seams) 21 formed by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com