Braking device for apparatuses driven by an electric motor

A braking device and motor technology, applied in electromechanical devices, braking actuators, electric components, etc., can solve problems such as the need to replace parts and affect explosion-proof performance, and achieve high-precision machining, cost and overall reliability advantages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

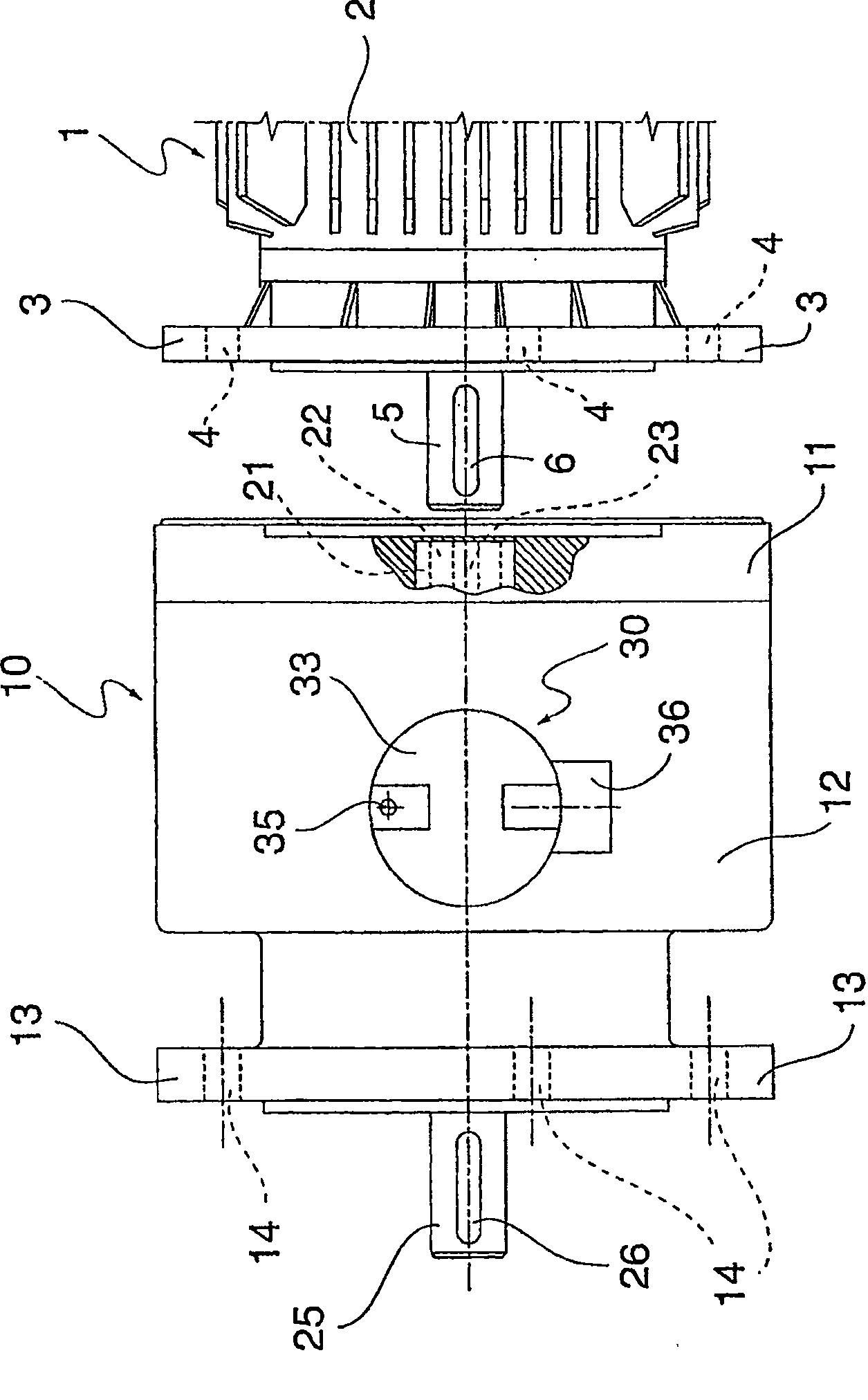

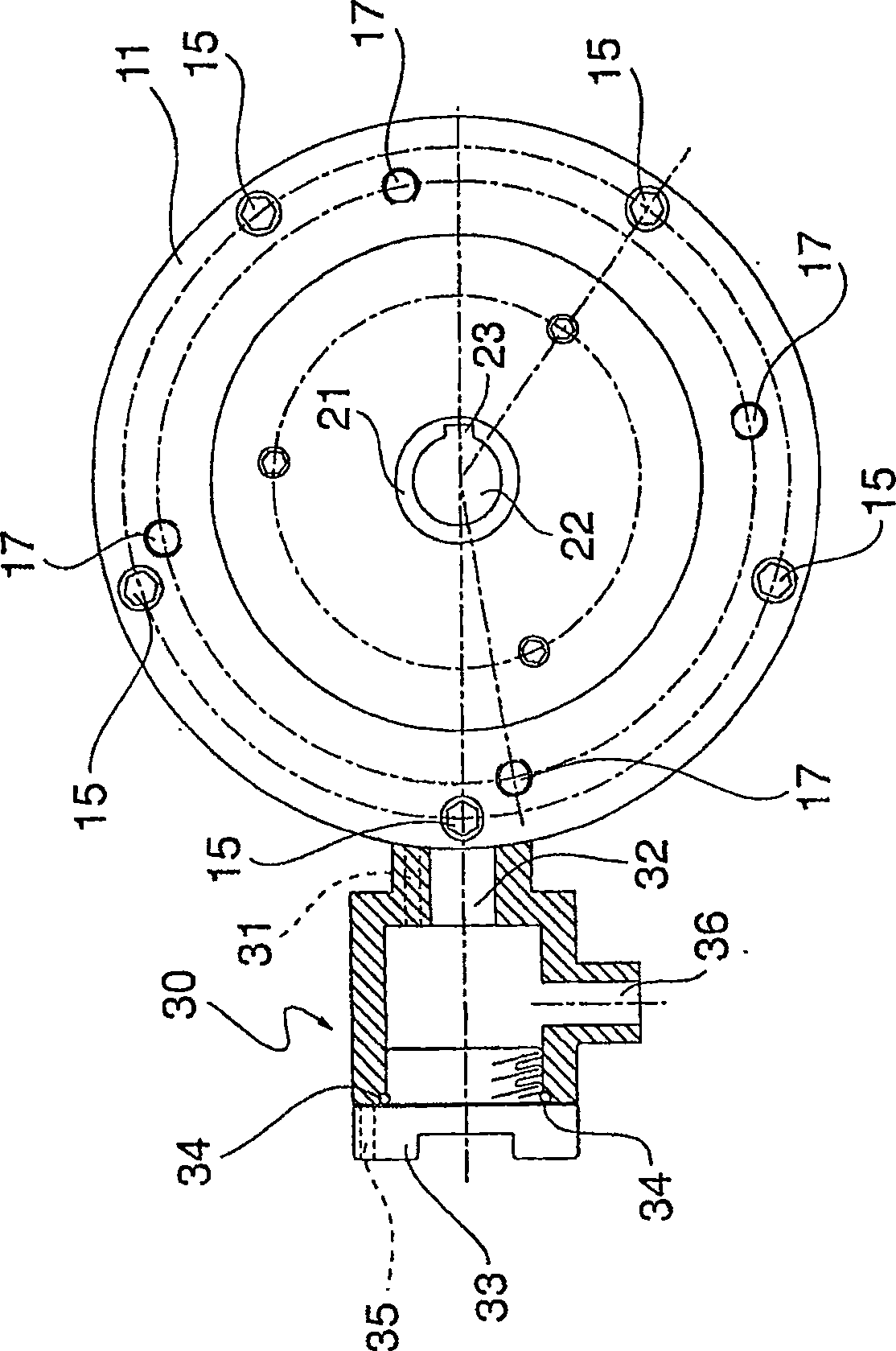

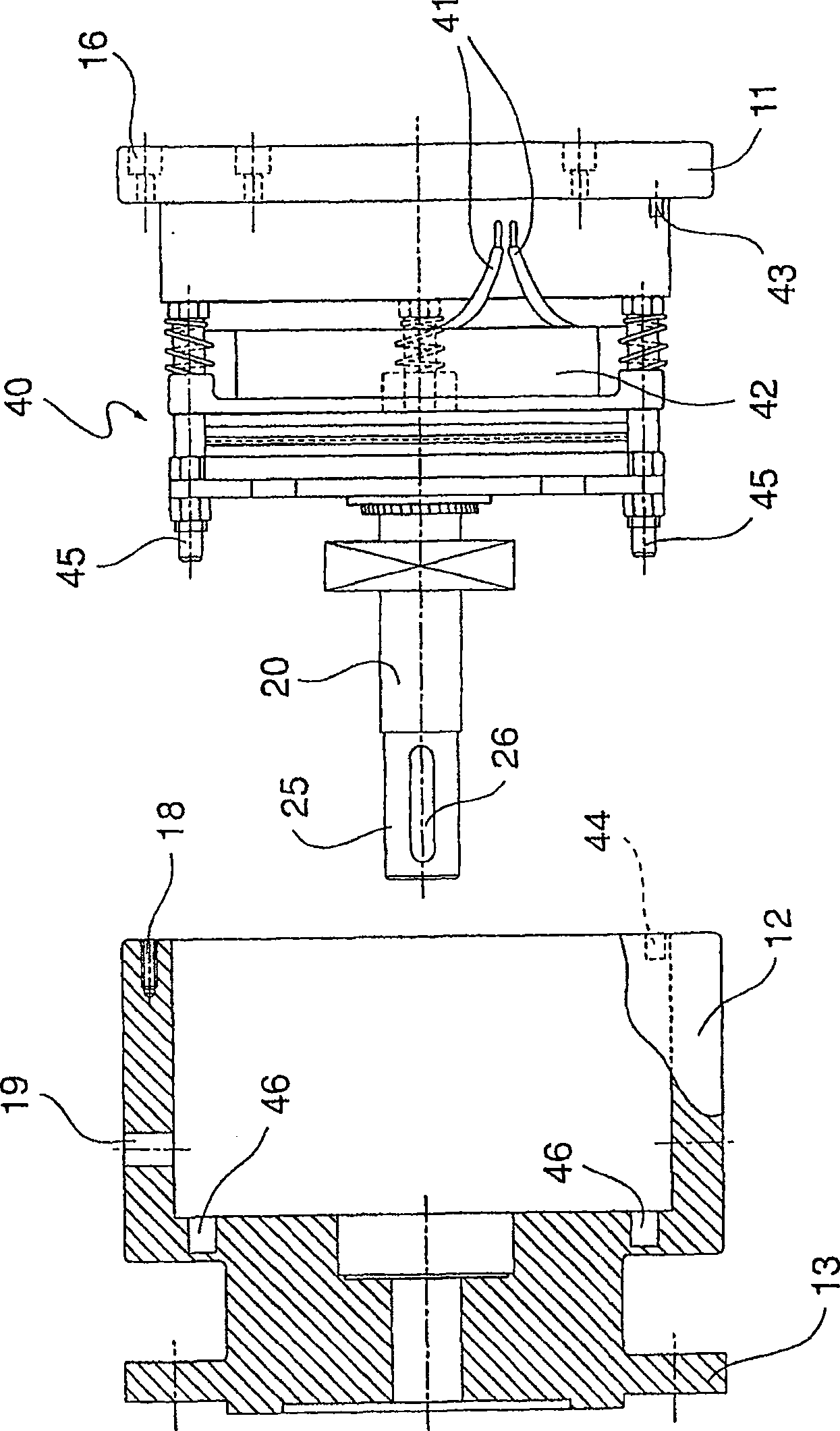

[0025] figure 1 Shown is the front of a motor 1, such as an explosion-proof motor, where a mounting flange 3 with through holes 4 is provided in front of the frame 2 to mount the motor using screws, bolts, etc. Projecting from the front of the frame 2 is an end portion 5 of the motor shaft, said end portion having a slot 6 for receiving known connectors such as keys.

[0026] The braking device 10 according to the embodiment shown here comprises a casing with an explosion-proof seal, wherein said casing consists of a first part 11 designed to be mounted on the flange 3 of the electric motor 1; The second part 12, which is provided with a seal, is fixed to the first part 11 in a detachable manner. The front of the second part 12 of the casing includes a mounting flange 13, wherein the mounting flange 13 can be of any shape and size, or a shape and size similar to the mounting flange 3 of the motor 1, such as figure 1 As shown, and with the through holes 14, its arrangement is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com