Method for fastening wrapping sheets in pulp-bale packaging, and fastening element

A wrapping and pulp bale technology, applied in the field of wrapping sheets, can solve problems such as reduced productivity and prolonged wrapping time, and achieve the effects of low consumption, cost avoidance, and prevention of staple connection loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

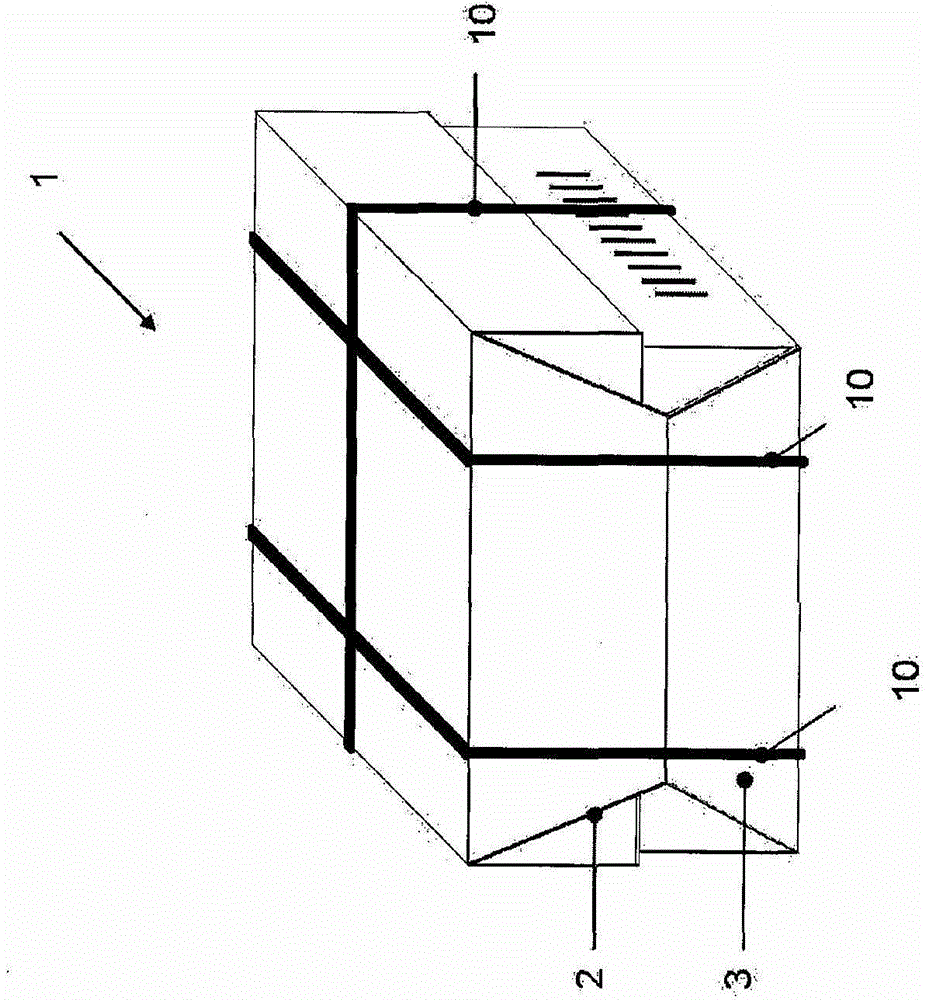

[0017] Figure 1a A view of a packaged pulp bale 1 according to the prior art is shown. This shows a variant with an upper 2 and a lower cellulose sheet 3 superimposed on each other. The two cellulose sheets are secured by means of strips 10 of paper.

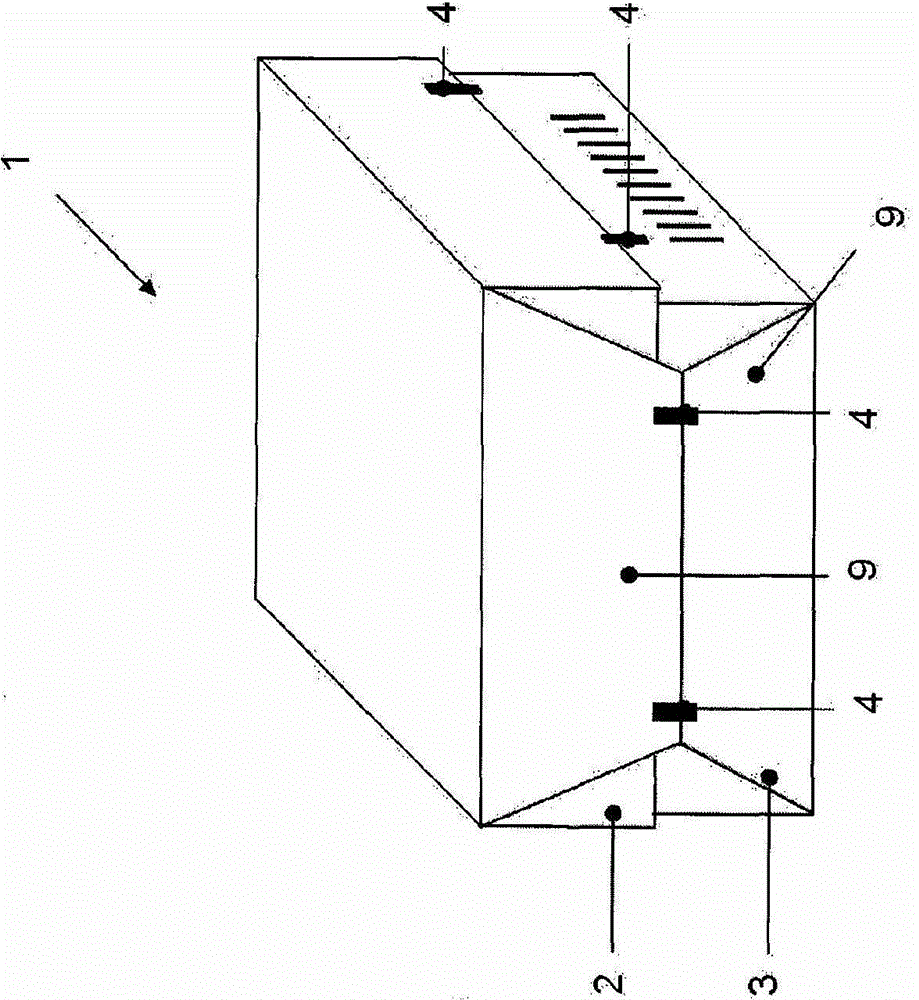

[0018] In contrast, Figure 1b A pulp bale 1 with cellulose sheets 2 , 3 secured by means of staples 4 is shown. It can be clearly seen here that, compared to the prior art, additional saving of paper or cellulose strips is achieved, the consumption of paper or cellulose strips corresponding to no more than about 20% of the variants according to the prior art to 25%. During wrapping with the one-piece wrapper made of paper, only the end folds, that is to say, the two folds 9 have to be fixed.

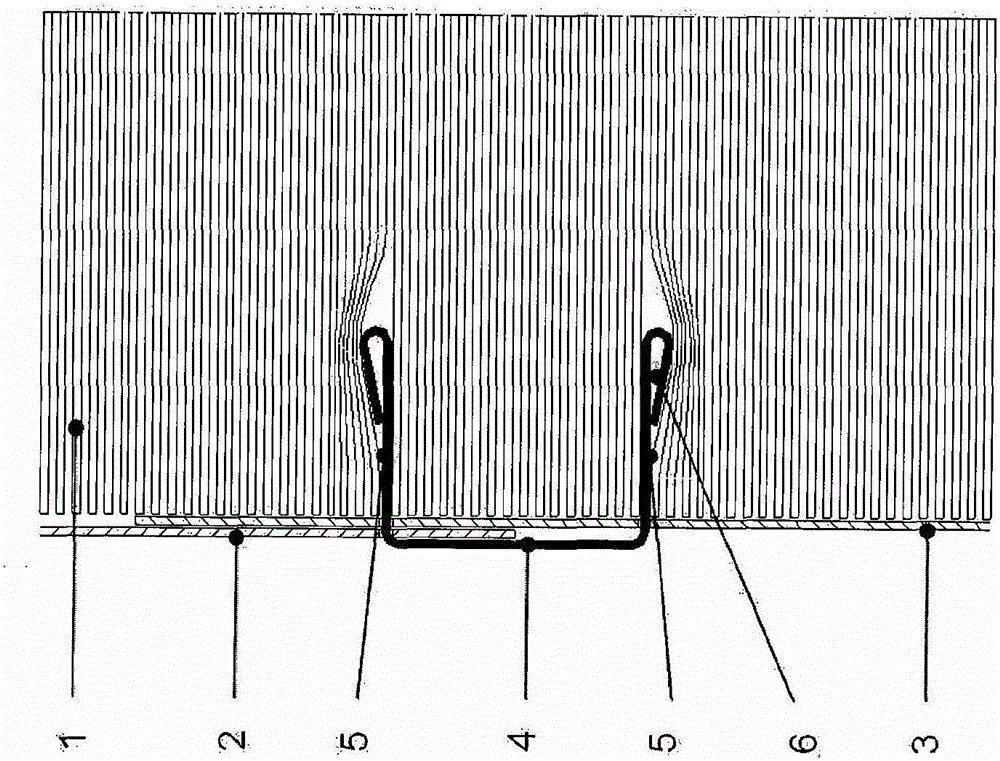

[0019] Figure 2a An already packaged pulp bale 1 (shown in cross-section) is shown as an example with an upper cellulose sheet 2 and a lower cellulose sheet 3 which overlap each other and must be Fastens securely to pulp bales. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com