MgO evaporation material

A technology for evaporating materials and pellets, applied in vacuum evaporation plating, metal material coating process, sputtering plating, etc., can solve problems such as wrong addressing and insufficient strength, improve brightness and reduce manufacturing costs , The effect of reducing the number of address ICs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

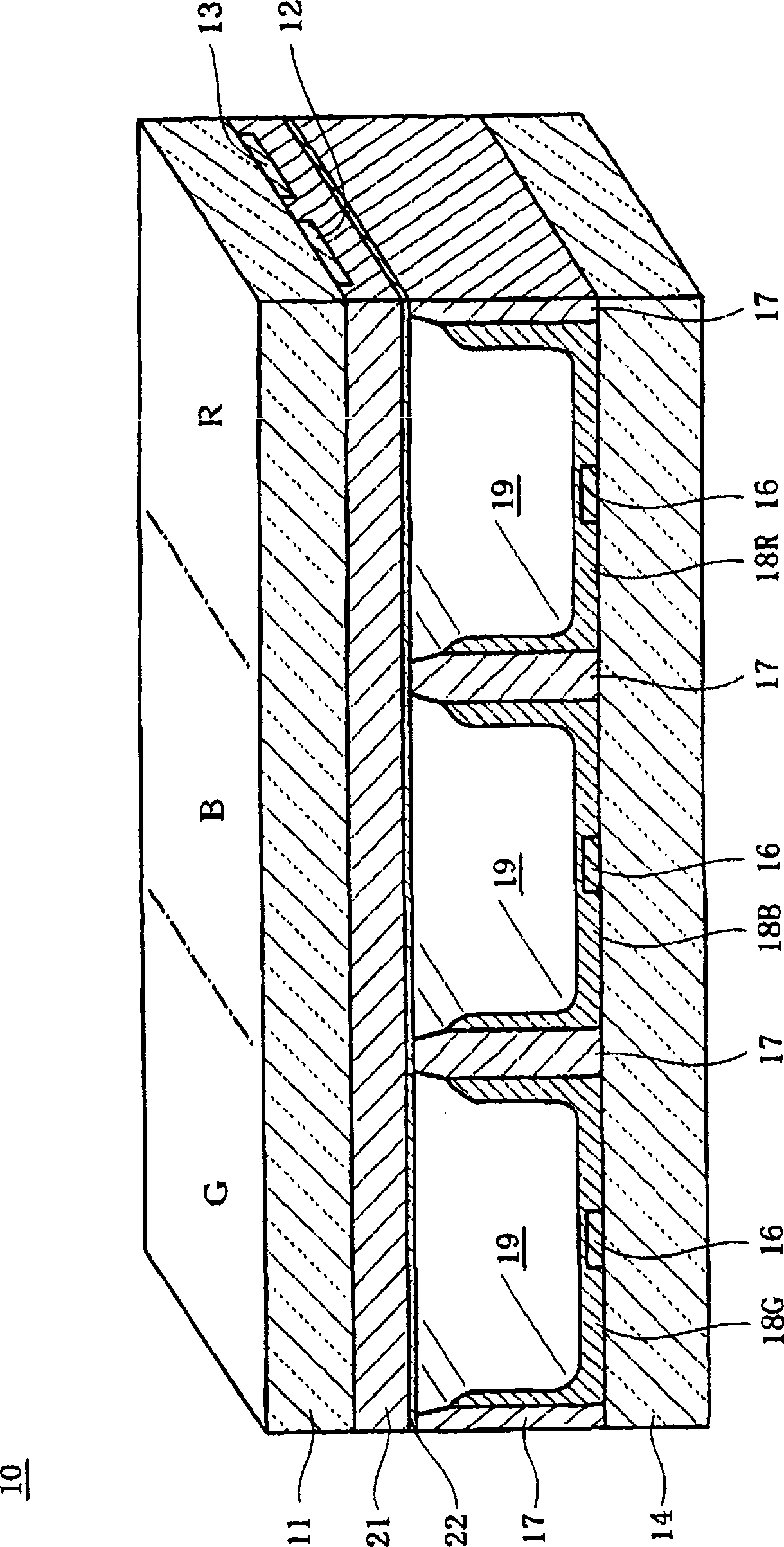

Image

Examples

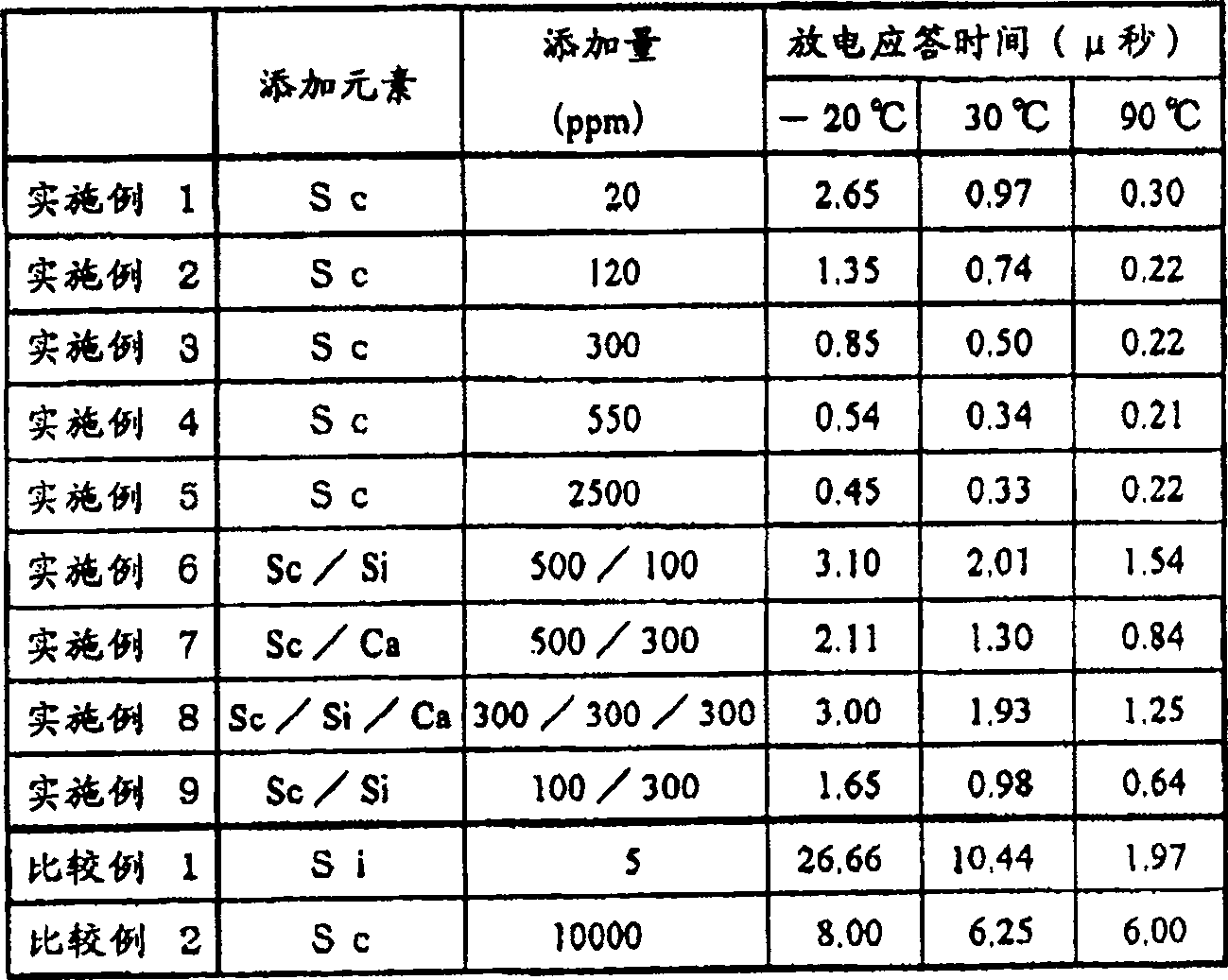

Embodiment 1

[0070] As a MgO vapor deposition material, polycrystalline MgO pellets with a purity of 99.95% of MgO, a relative density of 98%, and a concentration of Sc contained in MgO of 20 ppm were prepared. The diameter and thickness of the MgO vapor deposition material are 5 mm and 1.6 mm, respectively. In addition, an ITO electrode and a silver electrode were formed on the surface area to form electrodes, and in order to cover the electrodes, a glass substrate on which a dielectric glass layer was formed was prepared.

[0071] On the upper surface of the dielectric glass layer formed on the glass substrate, the above-mentioned MgO vapor deposition material was used to form a film thickness of (800nm), MgO film with (111) plane orientation. The film forming condition is that the final vacuum degree is 1.0×10 -4 Pa, oxygen partial pressure is 1.0×10 -2 Pa, substrate temperature is 200℃, film forming speed is / Sec (2nm / sec).

Embodiment 2

[0073] The MgO film was formed by the same method as in Example 1, except that a MgO vapor deposition material having a Sc concentration of 120 ppm contained in the MgO pellets was used.

Embodiment 3

[0075] The MgO film was formed by the same method as in Example 1, except that a MgO vapor deposition material with a Sc concentration of 300 ppm contained in the MgO pellets was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com