Door type solar energy warm booth production method

A solar energy and door-type technology, applied in botany equipment and methods, horticulture, greenhouse cultivation, etc., can solve the problems of roof bracket waterproof, anti-corrosion, poor performance, poor wall insulation effect, short service life of brackets, etc., to achieve The effect of improving the comprehensive index, prolonging the service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

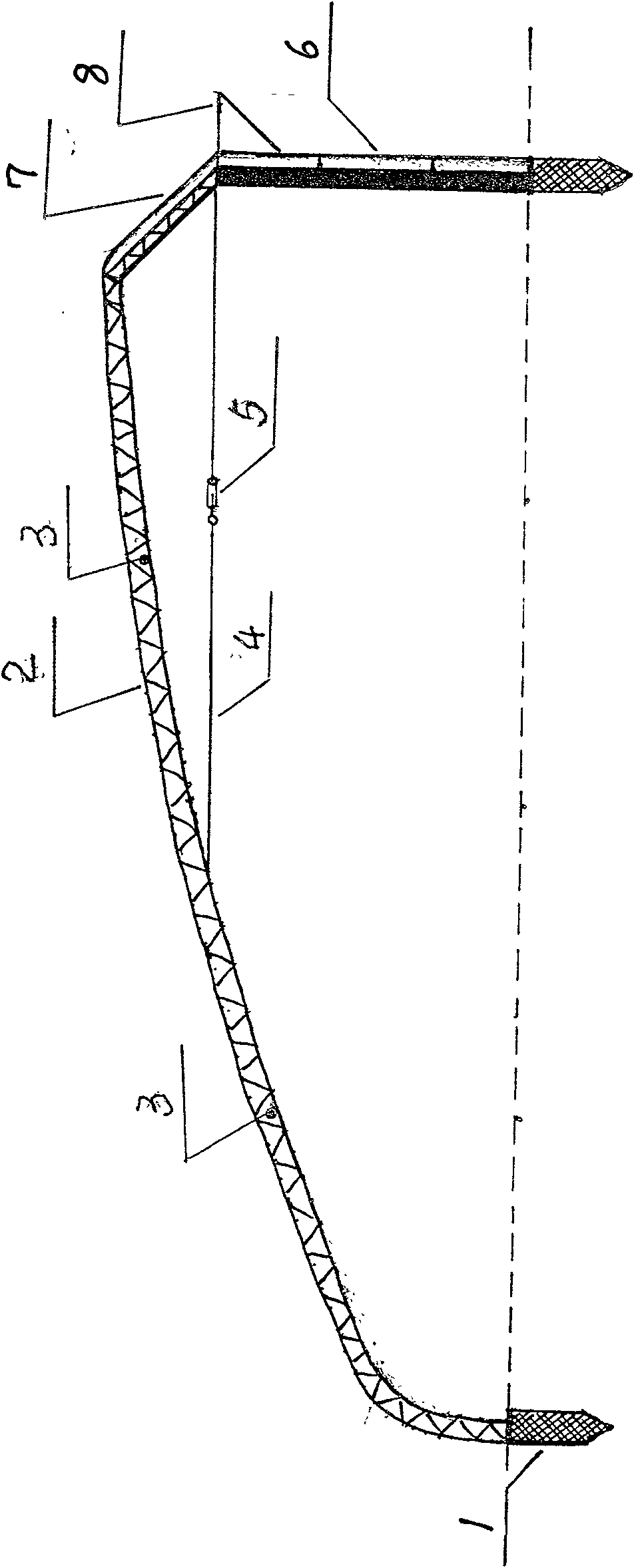

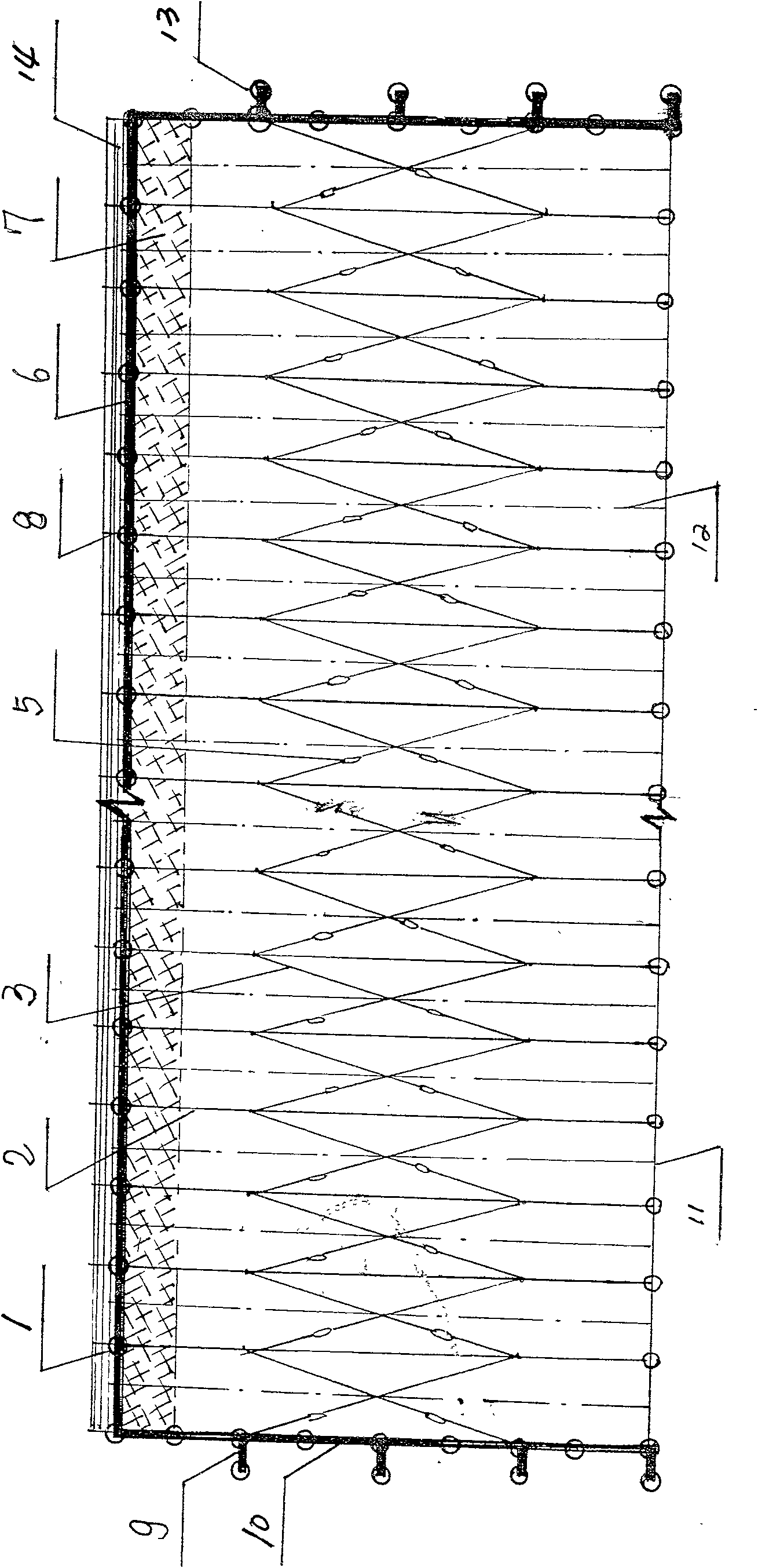

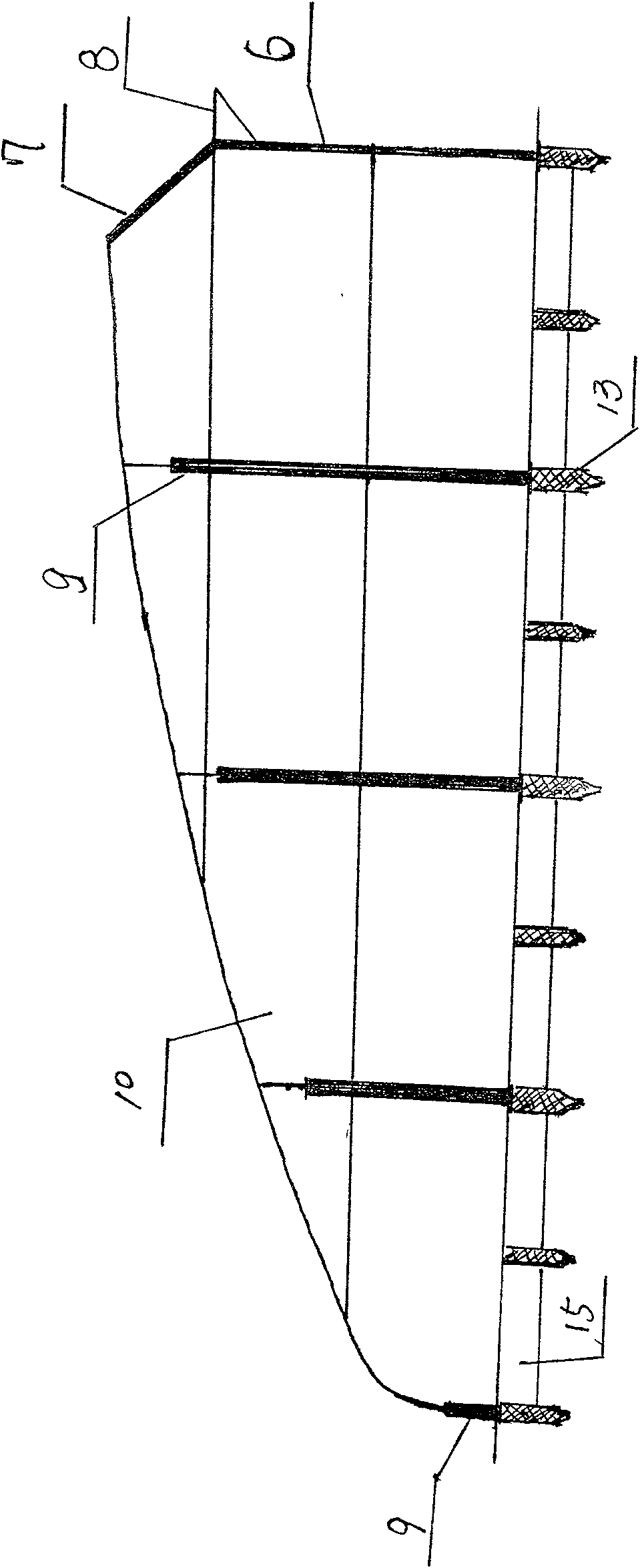

[0019] According to the winter climate conditions in Beijing, the width of the portal solar greenhouse is designed to be 8000mm, the distance between the portal trusses is 1200mm, and the height of the rear wall is 2000mm.

[0020] 1. For the production of foundation piles, set the pile height to 900mm and the side length to 120×120mm. The two sides of the pile are triangular grooves with a depth of 30 mm. A mold is made. Welding cage-type iron bars are placed in the mold, mixed according to the proportion of the polymer concrete mentioned above, mixed into a plastic slurry, poured into the mold, and vibrated and hardened. Demoulding, welding length 200mm, width 120mm, thickness 8mm at the pile head, flat iron plate, and foundation pile.

[0021] 2. For the production of freeze-insulated laminates, take 18kg / m 3 Polystyrene insulation board, length 1140mm, width 600mm, thickness 50mm, the upper edge and the left and right edges are cut into triangular tenons.

[0022] 3. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com