Light modulator

A technology for a dimming device and a mounting member, which is applied to lighting devices, light sources, and components of lighting devices, etc., can solve the problems of the bidirectional three-terminal thyristor Q being unable to maintain the conduction state and non-conducting, and achieve heat dissipation. Improves, suppresses temperature rise, and reduces assembly area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

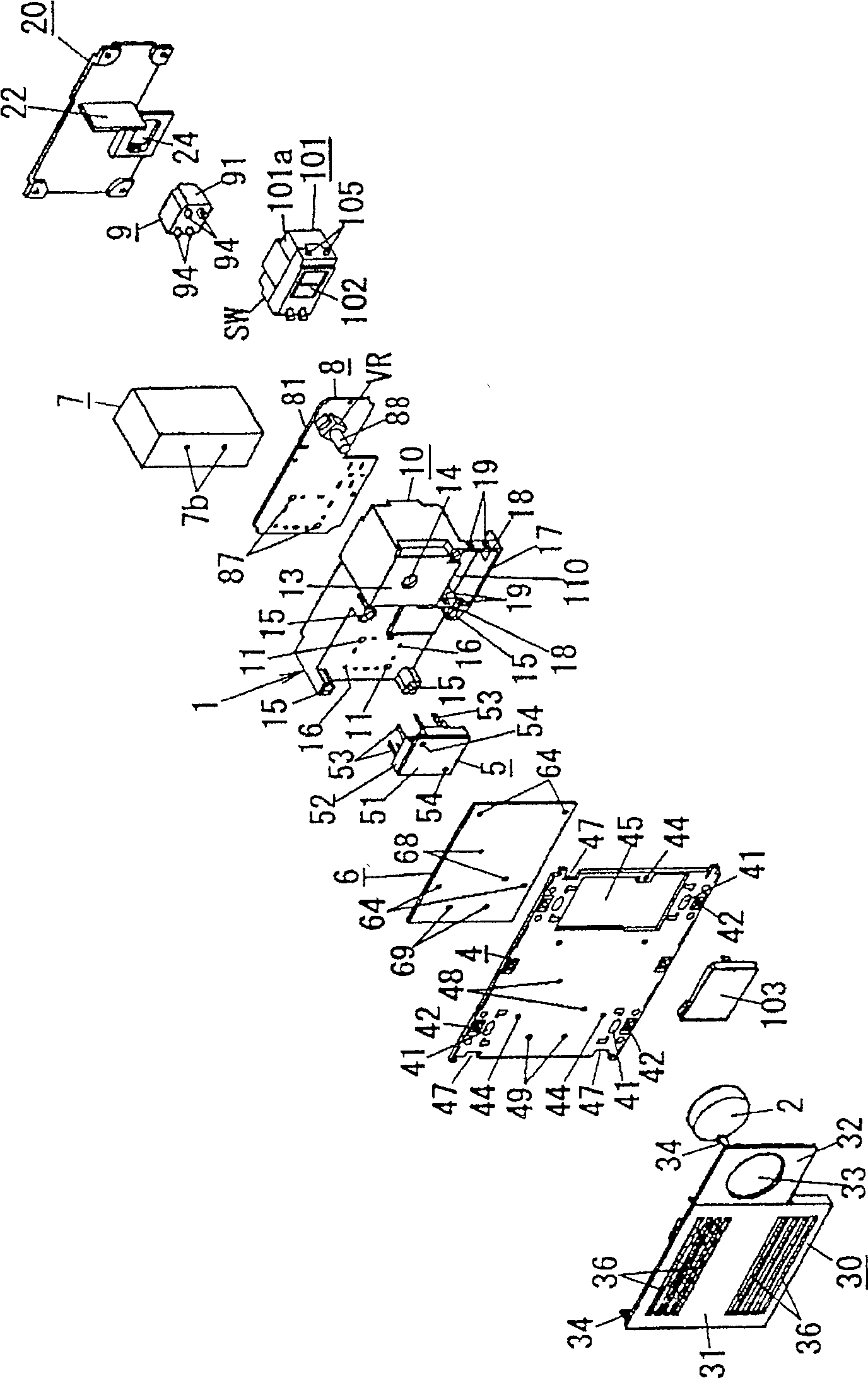

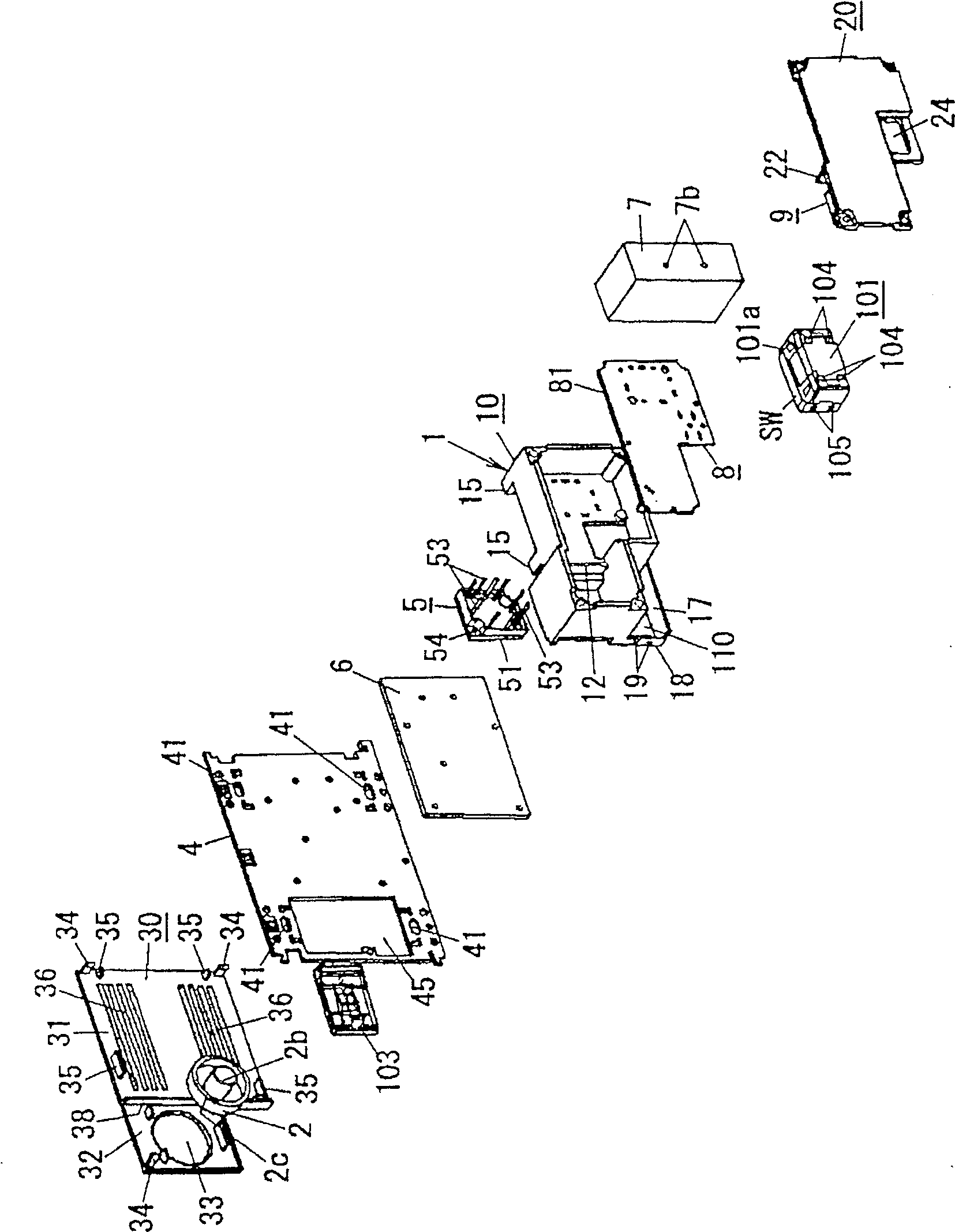

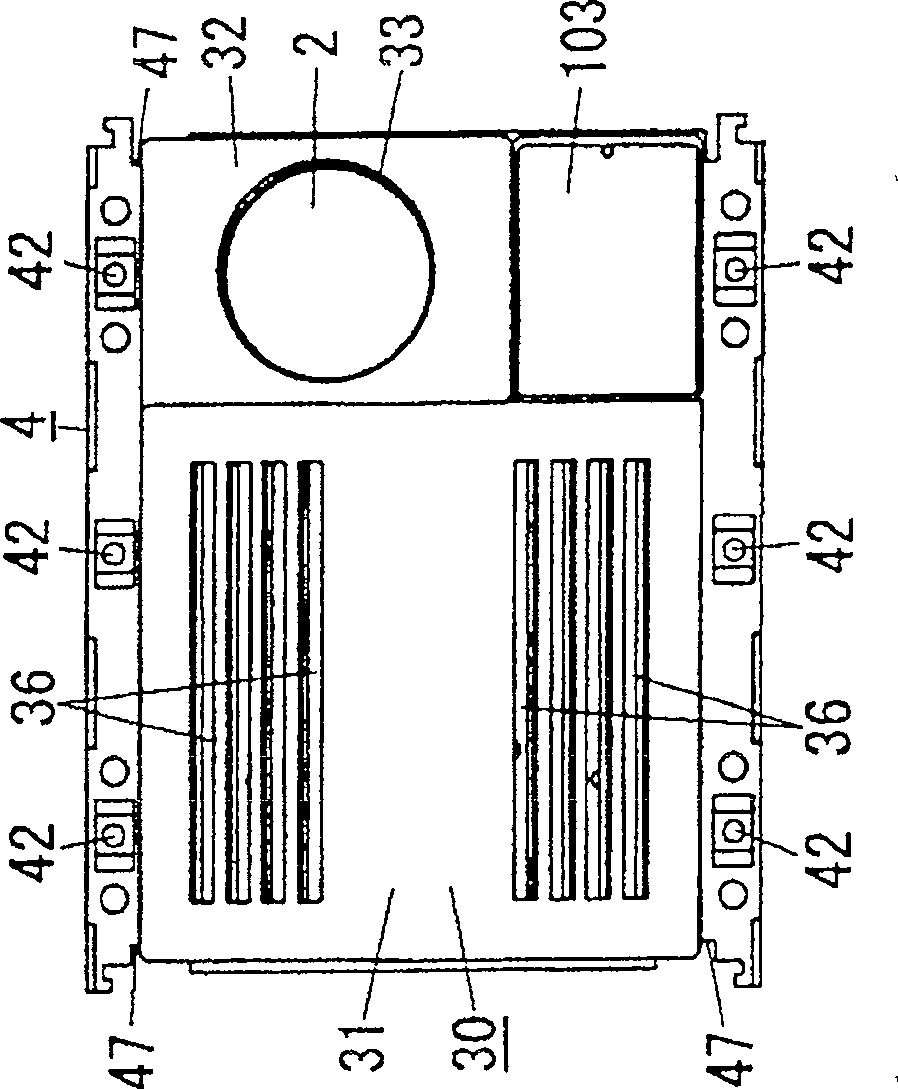

[0094] Below, refer to Figure 1 to Figure 10 The dimming device of this embodiment will be described. In addition, due to the circuit structure of the dimming device of this embodiment and Figure 13 The circuit structures shown are the same, and illustration and description are omitted.

[0095] The dimming device of this embodiment is constructed by embedding part of it in a construction surface such as a wall, and is used to control the dimming of lighting loads La such as incandescent lamps. The metal mounting plate 4 corresponding to the triple use mounting frame used in the type wiring appliance. That is, the mounting plate 4 is formed of a metal material such as aluminum, and the overall shape is formed so that three of them can be installed in three rows in a row. Corresponds to the installation frame for triple use of the unit size of the installation of up to 3 units of wiring equipment (the external dimension is formed to be equal to the installation frame for t...

Embodiment 2

[0119] The basic structure of the dimming device of this embodiment is roughly the same as that of Embodiment 1. It is characterized in that the material used in Embodiment 1 is the heat dissipation plate 6 and heat dissipation block 7 of the thermal bonding member and the installation plate 4 of the installation member. The same metal material (such as aluminum), such as Figure 11 As shown, the heat dissipation plate 6, the installation plate 4 and the heat dissipation block 7 are integrally formed by metal mold casting (aluminum mold casting), which is the same as the case where the heat dissipation plate 6, the installation plate 4 and the heat dissipation block 7 are separately formed as in Embodiment 1. Ratio, the assembly is improved, and the thermal conductivity is improved, and the heat dissipation efficiency is improved. Since other structures are the same as those in Embodiment 1, explanations are omitted. In this embodiment, the heat sink plate 6, the mounting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com