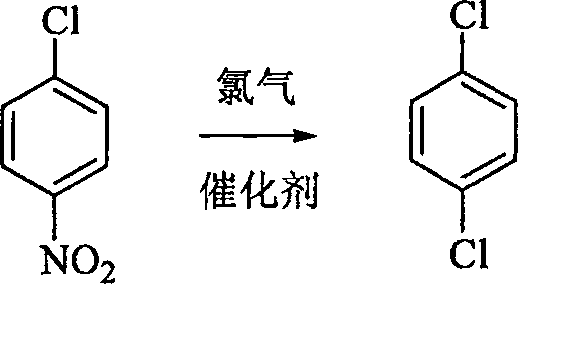

Method for synthesizing p-dichlorobenzene

A technology of p-dichlorobenzene and p-nitrochlorobenzene, which is applied in the field of synthesis of p-dichlorobenzene, can solve the problems of small scale, difficult separation, and poor product quality, and achieve mild reaction conditions, simple process operation, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 15.8 grams (0.1 moles) of p-nitrochlorobenzene and 0.08 grams of catalyst benzoyl peroxide into the reaction flask, heat to 200 ° C, and feed chlorine gas to react for 6 hours to obtain the crude product of p-dichlorobenzene, which is rectified Column rectification, obtains the product 13.6 grams of purity ≥ 99.5%, yield 93%. The melting point is 52-53°C. The brown-red gas (nitroxyl chloride) produced during the reaction is absorbed with ammonia and ammonium chloride liquid.

Embodiment 2

[0024] Add 15.8 grams (0.1 moles) of p-nitrochlorobenzene and 0.08 grams of catalyst azobisisobutyronitrile into the reaction flask, heat to 200 ° C, and feed chlorine gas to react for 6 hours to obtain the crude product of p-dichlorobenzene. Distillation column rectification, obtains the product 13.8 grams of purity ≥ 99.5%, yield 94%. The melting point is 52-53°C. The brown-red gas (nitroxyl chloride) produced during the reaction is absorbed with ammonia and ammonium chloride liquid.

Embodiment 3

[0026] Add 15.8 g (0.1 mole) of p-nitrochlorobenzene and 0.1 g of catalyst azobisisobutyronitrile into the reaction flask, heat to 150° C., and feed chlorine gas to react for 6 hours to obtain the crude p-dichlorobenzene, which is refined and purified. Distillation column rectification, obtains the product 13 grams of purity ≥ 99.5%, yield 89%. The melting point is 52-53°C. The brown-red gas (nitroxyl chloride) produced during the reaction is absorbed with ammonia and ammonium chloride liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com