Fiber reinforcement type brittle composite material pipeline coatings, its coating method and pipeline

A fiber-reinforced, composite material technology, used in rigid pipes, pipeline protection, pipeline anti-corrosion/rust protection, etc., can solve the problems of limitation, complex preparation process, high brittleness, etc. Effect of Material Amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

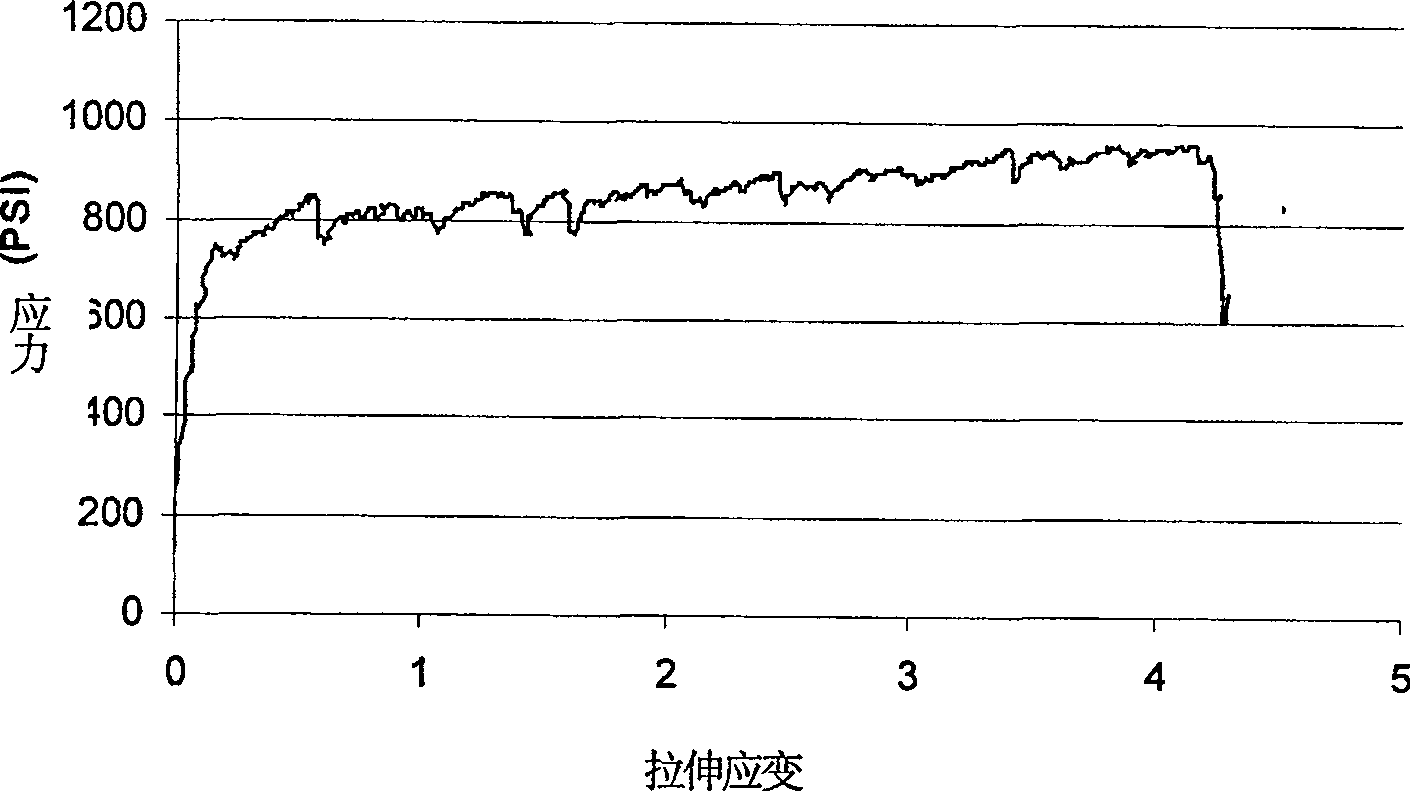

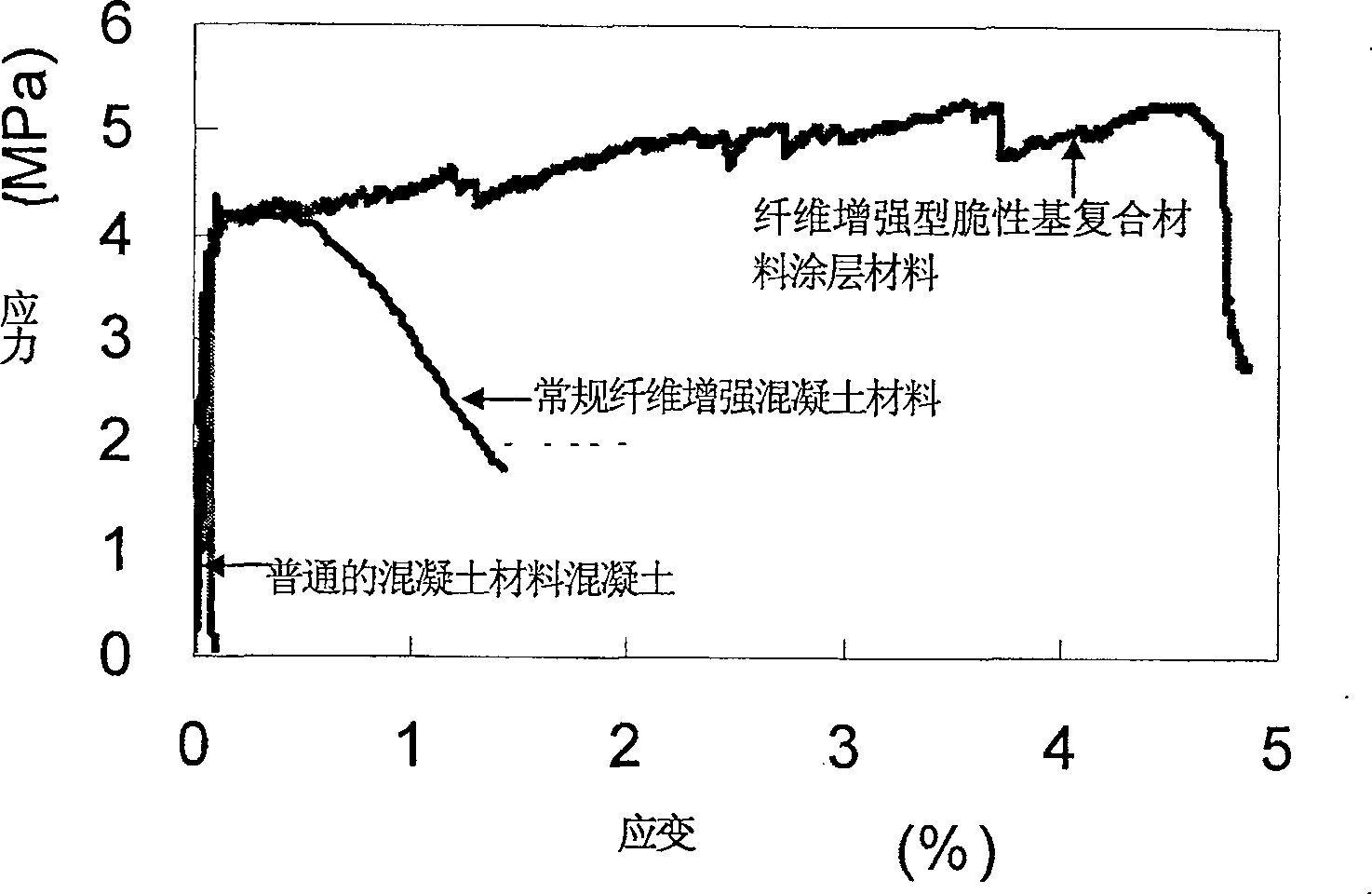

[0032] Example 1: Composition and ratio of fiber-reinforced brittle-matrix composite material.

[0033] The fiber-reinforced brittle-matrix composite material is proportioned as follows: the weight of ordinary No. I Polish cement is 1 unit, and the weight ratios of silica sand, fly ash, water and water-reducing agent to cement are 0.5:1.2:0.5:0.01, respectively; The total volume ratio of the polyvinyl alcohol fibers to the above raw materials after mixing was 0.01.

Embodiment 2

[0034] Example 2: Composition and ratio of fiber-reinforced brittle-matrix composite material.

[0035]The fiber-reinforced brittle-matrix composite material is proportioned as follows: the weight of ordinary No. I Polish cement is 1 unit, and the weight ratios of silica sand, iron ore sand, water and water-reducing agent to cement are 0.8:1.5:0.8:0.03; The total volume ratio of the steel fiber to the above raw materials after mixing was 0.02.

Embodiment 3

[0036] Example 3: Composition and ratio of fiber-reinforced brittle-matrix composite material.

[0037] Fiber-reinforced brittle-matrix composites are proportioned as follows: the weight of ordinary No. I Polish cement is 1 unit, and the weight ratios of silica sand, carbon powder, water and water-reducing agent to cement are 2.0:1.4:0.6:0.02; glass The total volume ratio of the fibers to the above raw materials after mixing was 0.04.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com