Power shift type automatic transmission system

A technology of automatic shifting and power shifting, which is applied in the direction of transmission, gear transmission, transmission control, etc., can solve problems such as idleness, improve power and driving comfort, realize power shift performance, and improve power Effects on performance and fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

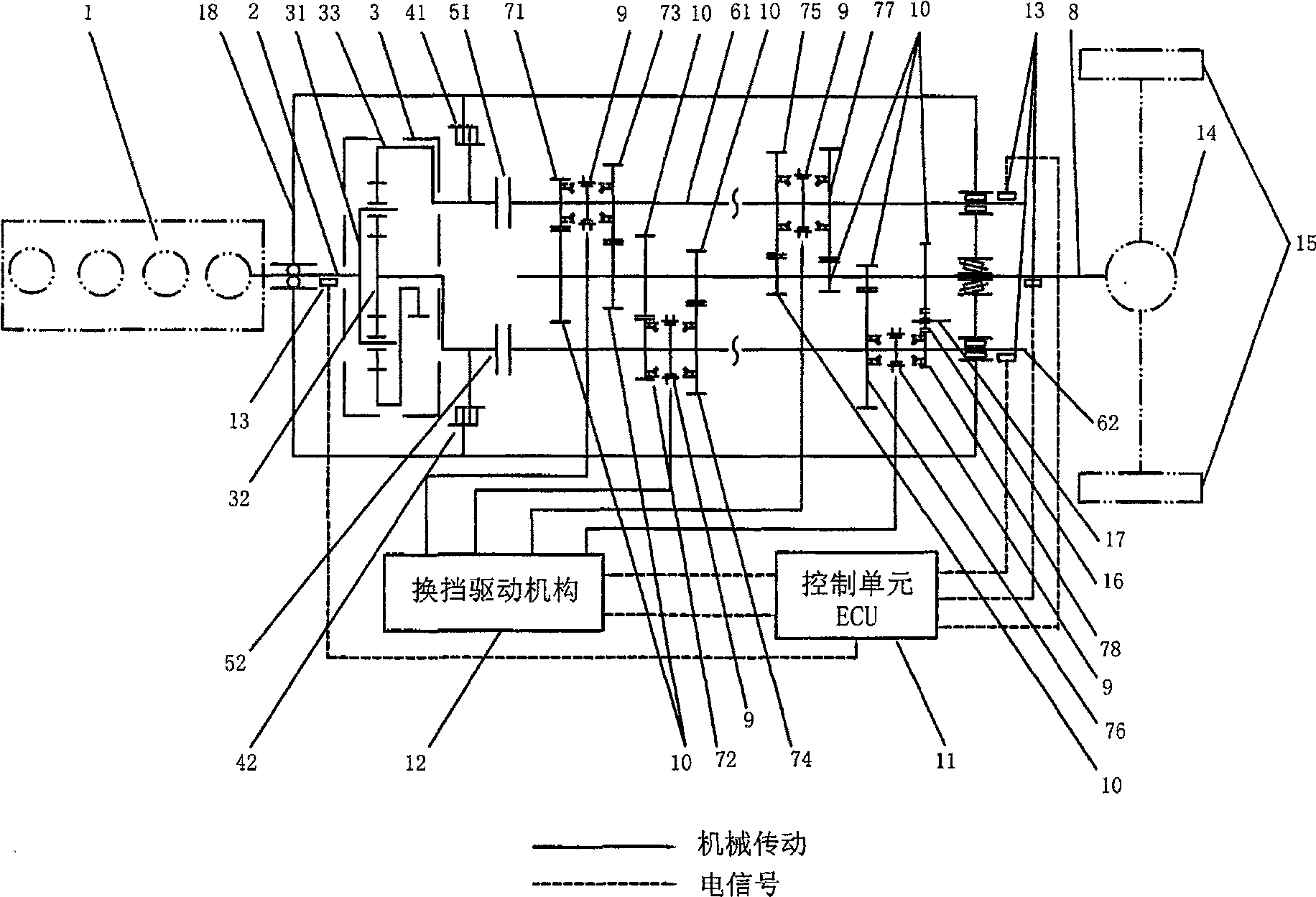

[0050] Example 1: Transformation of the transmission of a dual-clutch automatic transmission car with four forward gears

[0051] Such as figure 2 Shown: A single planetary planetary mechanism and two brakes are added between the engine and the gearbox. One end of the input shaft 2 is connected to the crankshaft of the engine 1, and the other end is connected to the planet carrier 31 of the planetary mechanism 3 as a power input end. . The ring gear 33 and the sun gear 32 of the planetary mechanism 3 are respectively connected to the driving discs of the first clutch 51 and the second clutch 52; one end of the first brake 41 is fixed to the housing of the gearbox 18, and the other end is connected to the planetary mechanism The ring gear 33 of 3 is connected; one end of the second brake 42 is also fixed to the housing of the gearbox 18, and the other end is connected to the sun gear 32 of the planetary mechanism. The rotation of the ring gear 33 and the sun gear 32 is controlled ...

Embodiment 2

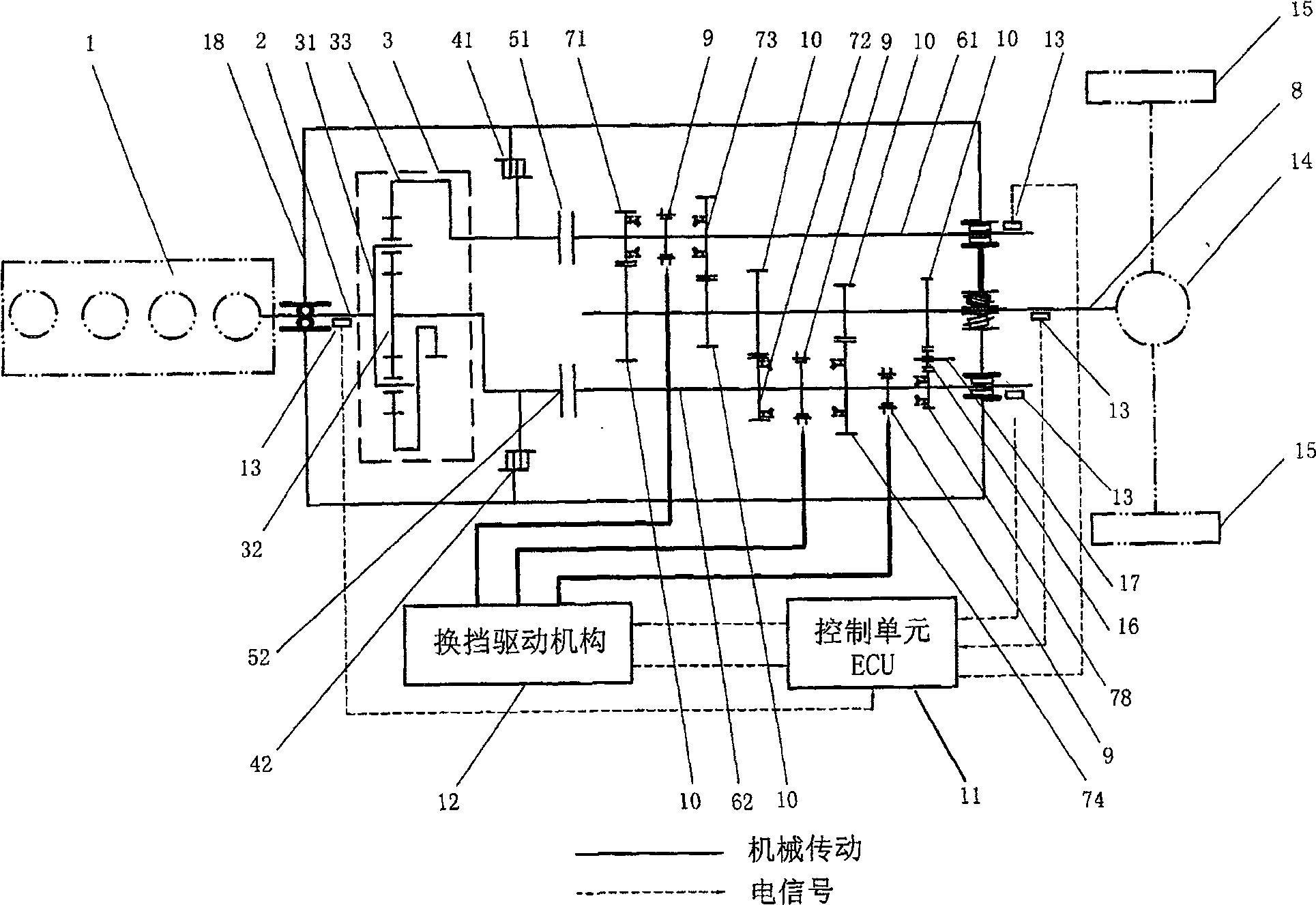

[0068] Such as image 3 Shown. Its structural arrangement is basically the same as that of Embodiment 1, except that the gearbox adds two intermediate transition shafts. One of the power transmission shafts 61 is hollowed with a forward gear 71 and a driving gear 73; the power transmission shaft 62 is hollow with a forward gear second 72, a fourth 74 driving gear 74 and power transmission. Reverse gear 78; one of the driving gear 71 on one of the power transmission shafts 61 and the third driving gear 73 respectively mesh with the driven gear 10 on one of the intermediate shafts 201; one of the driving gears on the second power transmission shaft 62 No. 73 and No. 74 of the driving gear respectively mesh with the driven gear 10 on the No. 2 of the intermediate shaft 202. The reverse gear 16 is freely sleeved on the reverse shaft 17 and is respectively connected to the power transmission shaft No. 62 of the power transmission. The gear 78 meshes with the driven reverse gear 10 on t...

Embodiment 3

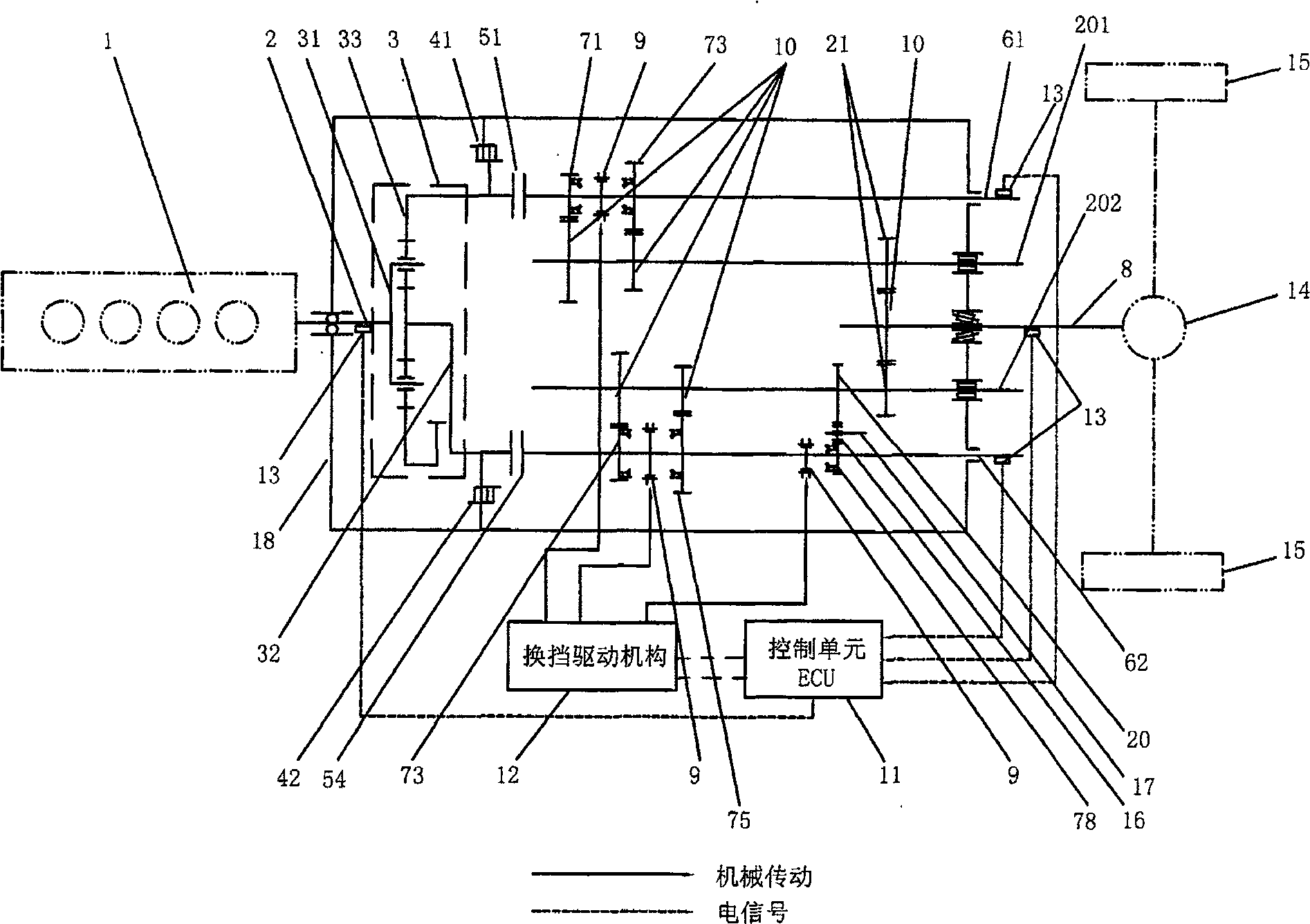

[0071] Such as Figure 4 Shown. Used on the same vehicle transmission as in Example 1. The specific arrangement is to add a single planetary row planetary mechanism 3 between the engine and the gearbox and cooperate with two double-sided clutches. The planetary carrier 31 of the planetary mechanism is used as the power input end and is connected with the output shaft of the engine 1, and the ring gear 33 and the sun gear 32 of the planetary mechanism 3 are respectively used as the power output ends and are respectively connected to the driving discs of the two clutches (consisting of the housing of the double-sided clutch). One) connected. The difference from Example 1 is that two double-sided clutches are used. The two driven discs of one of the double-sided clutches 45 can be regarded as two output ends, one end of which is fixedly connected to the transmission housing 18 as a whole, and the other end is connected to one of the transmission power transmission shafts 61; One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com