Car engine camshaft bearing cap

A technology for automobile engines and camshafts, which is applied to engine components, machines/engines, cylinder heads, etc., can solve the problems of complicated processing technology of oil holes in cylinder heads, increased engine volume and large frame volume, etc., and can reduce the machining process. Difficulty, compact structure, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the automobile engine camshaft bearing cap of the present invention is described in further detail.

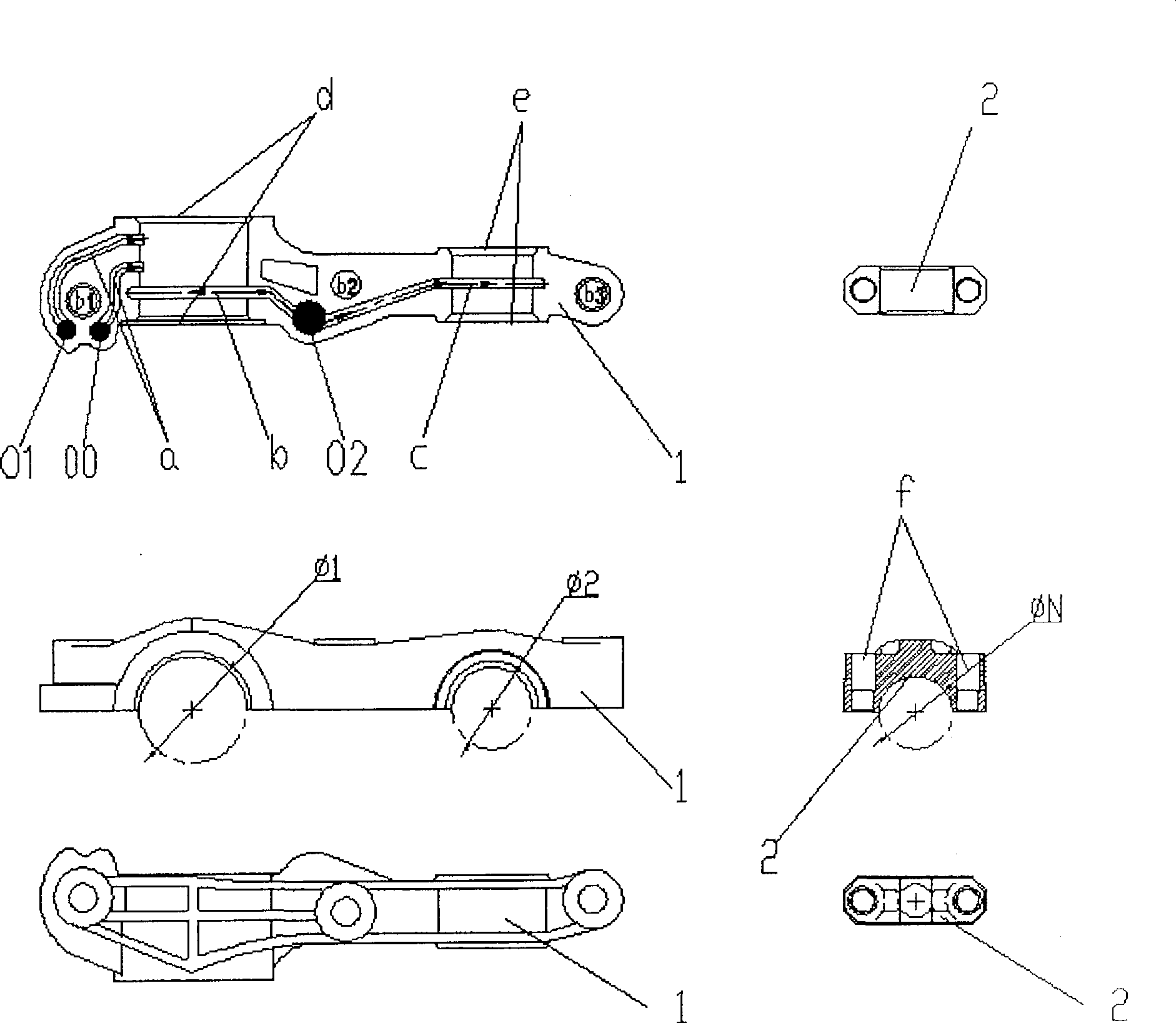

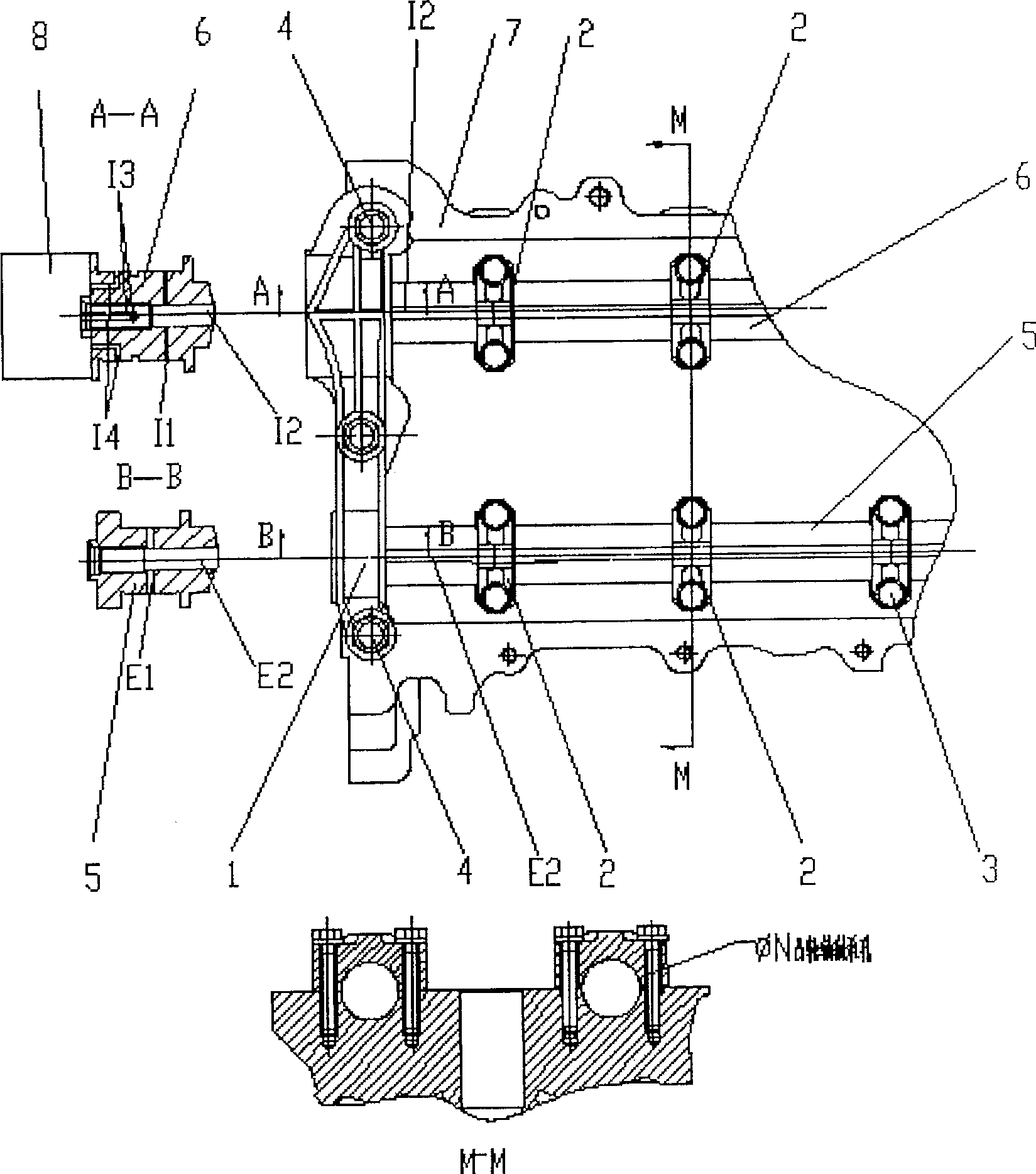

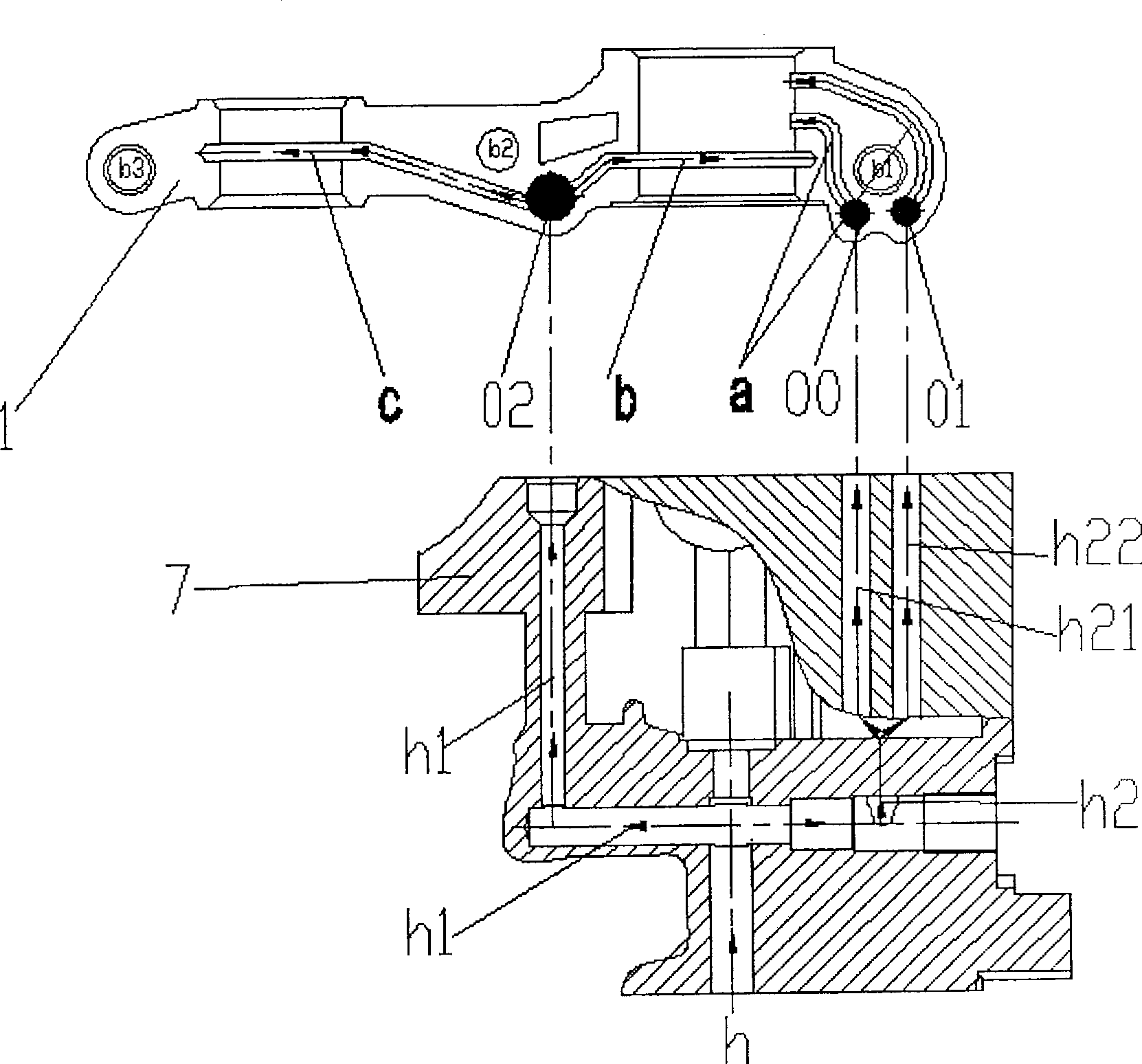

[0019] refer to figure 1 , 3 , discloses the automobile engine camshaft bearing cap of the present invention, comprises the first camshaft bearing cap 1, the second to N camshaft bearing caps 2, that is, there are multiple bearing caps with the same structure as the second camshaft bearing cap. First camshaft bearing cap 1 and multiple second camshaft bearing caps figure 2 Installed on the engine cylinder head 7, constitute the shaft diameter holes φ1, φ2 and several φN of the camshafts 5, 6 together. The first camshaft bearing cap 1 is positioned by combining the two positioning sleeves 4 installed on the cylinder head 7 with the cylinder head, and the second to N camshaft bearing caps 2 are positioned by combining the positioning bolts 3 with the cylinder head 7 , to ensure the coaxiality of the camshaft hole. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com