Stud welding laser locating system and working method thereof

A working method and stud welding technology, which is applied in the direction of manufacturing tools, welding equipment, welding accessories, etc., can solve problems such as shape, size deformation, welding position error, and tolerance inconsistency, so as to save installation time, improve product quality, and install flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

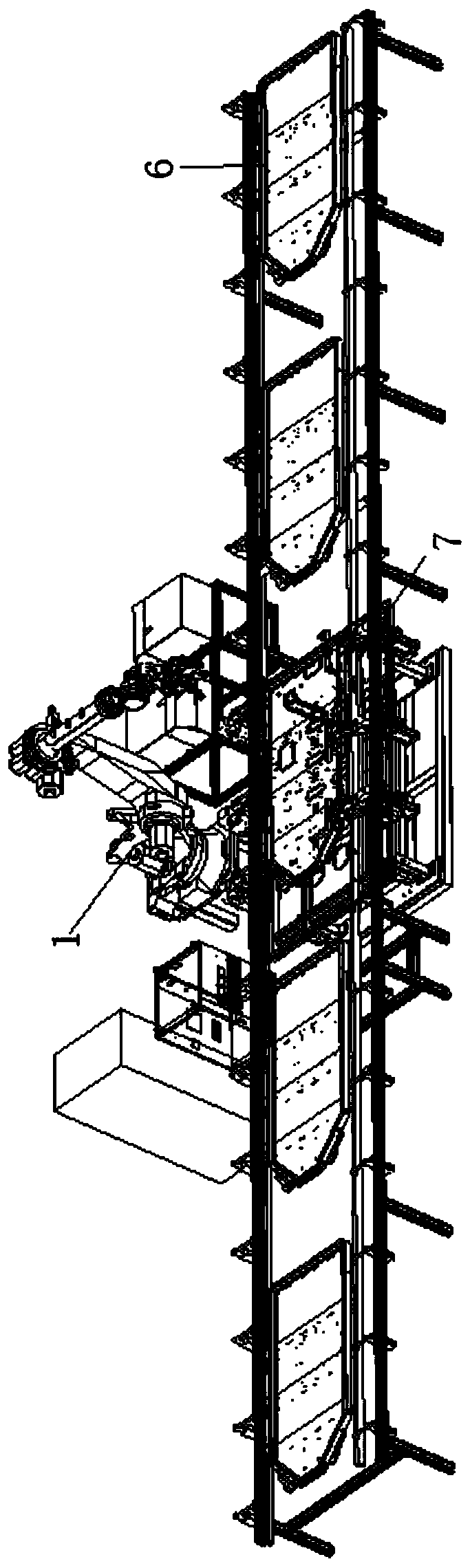

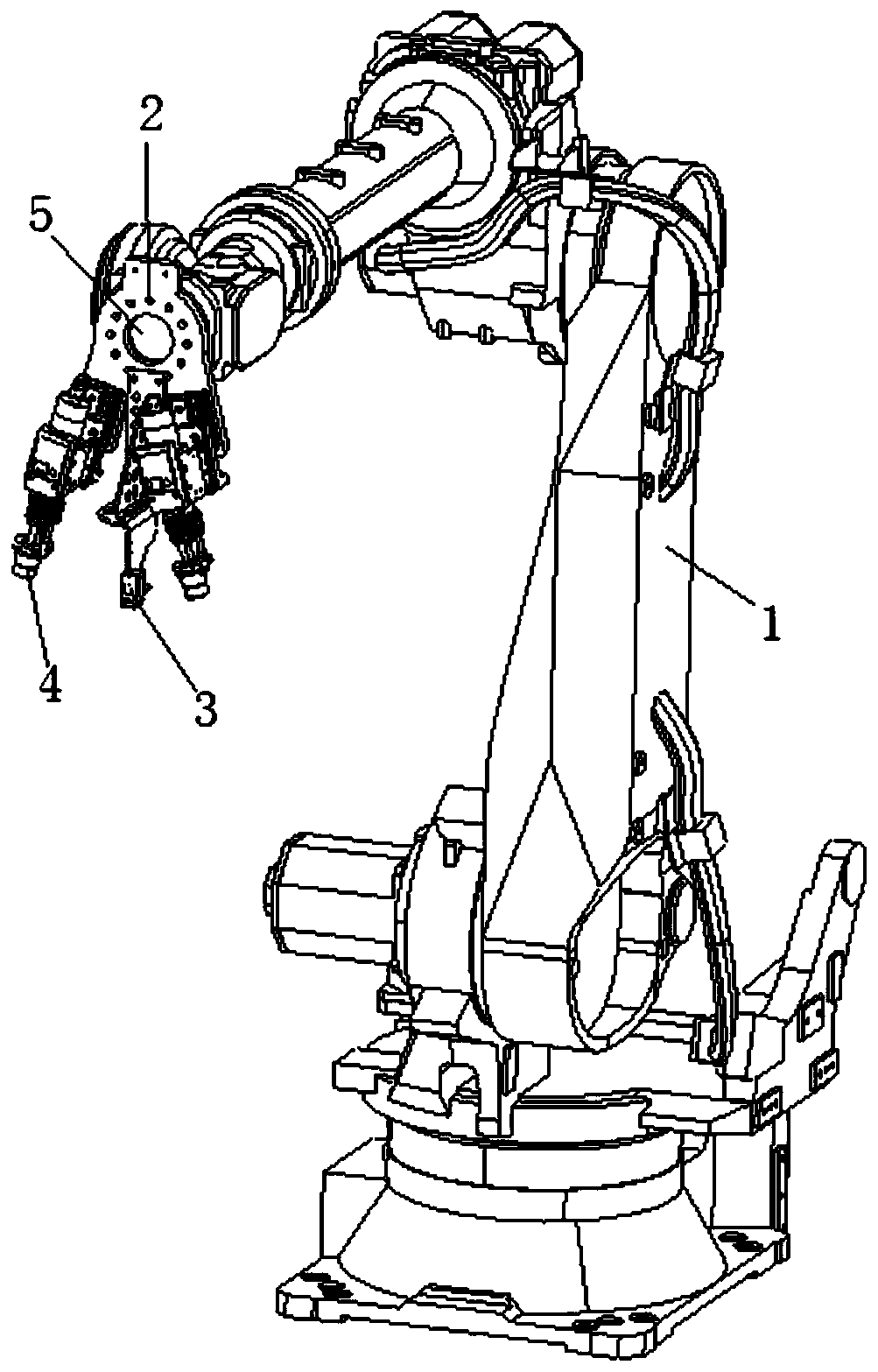

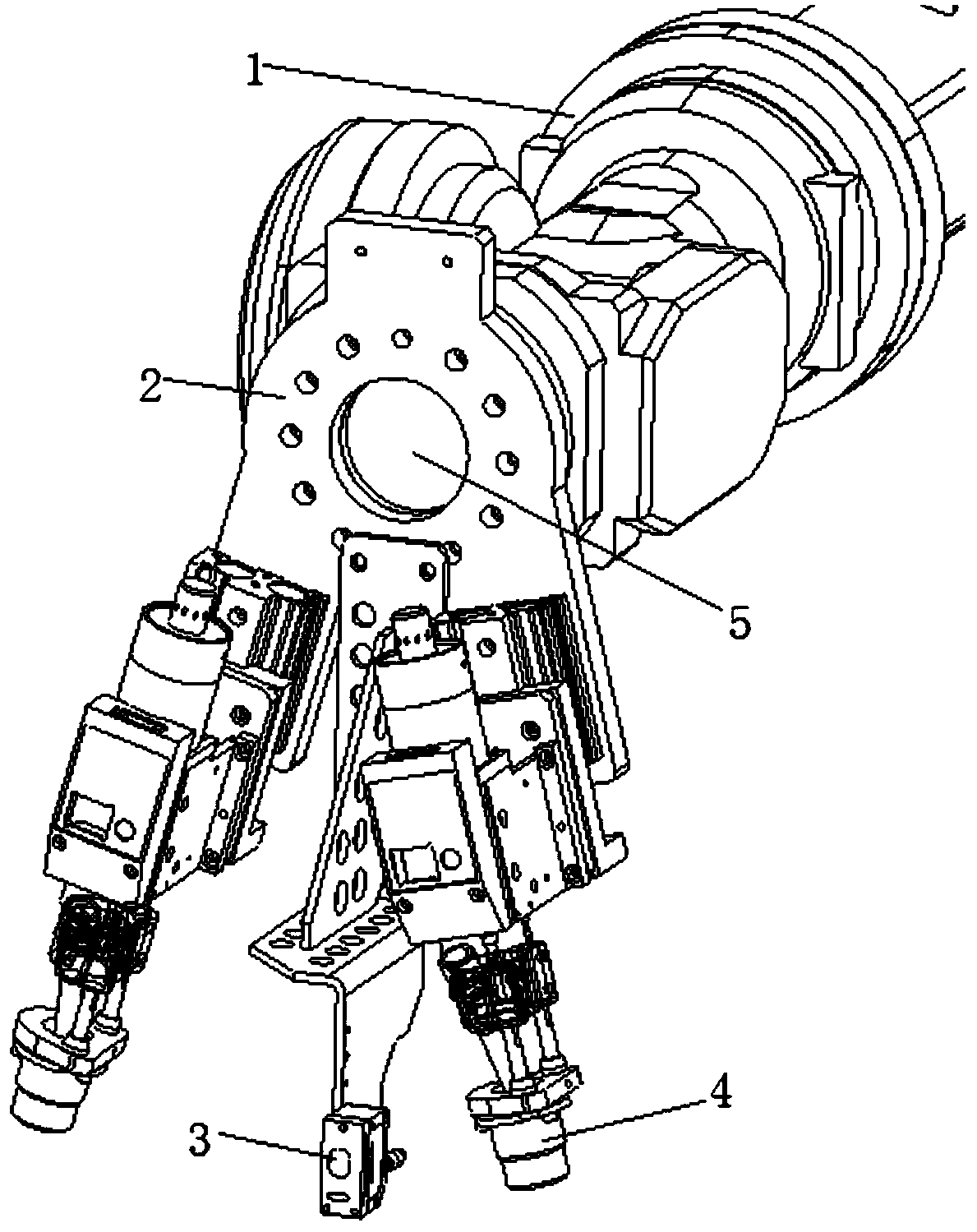

[0023] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0024] Such as Figure 1 to Figure 3 As shown, a stud welding laser positioning system includes a multi-axis robot 1, one end of the multi-axis robot 1 is fixed, and the other end of the multi-axis robot 1 is provided with a mounting base 2. A laser position sensor 3 and a stud welding torch 4 are arranged on the installation base 2 .

[0025] Specifically, the installation base 2 is connected to the multi-axis robot 1 through an end rotating shaft 5 , and the laser position sensor 3 and the stud welding torch 4 are arranged along the radial direction of the end rotating shaft 5 . There are multiple stud welding guns 4 and they are respectively used for welding studs of different specifications. It also includes an assembly line platform 6 in which a welding station 7 is arranged, and the multi-axis robot 1 is arranged on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com