Cotton roll equal length gradually pressurizing structure and control device thereof

A technology of gradually increasing pressure and lap, applied in the field of blowing and rolling machines, can solve the problems of poor effect, unreasonable, and the draft length of cotton lap does not meet the national standard, etc., and it is more scientific to achieve reasonable pressure on the cotton layer. , the effect of accurate value accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

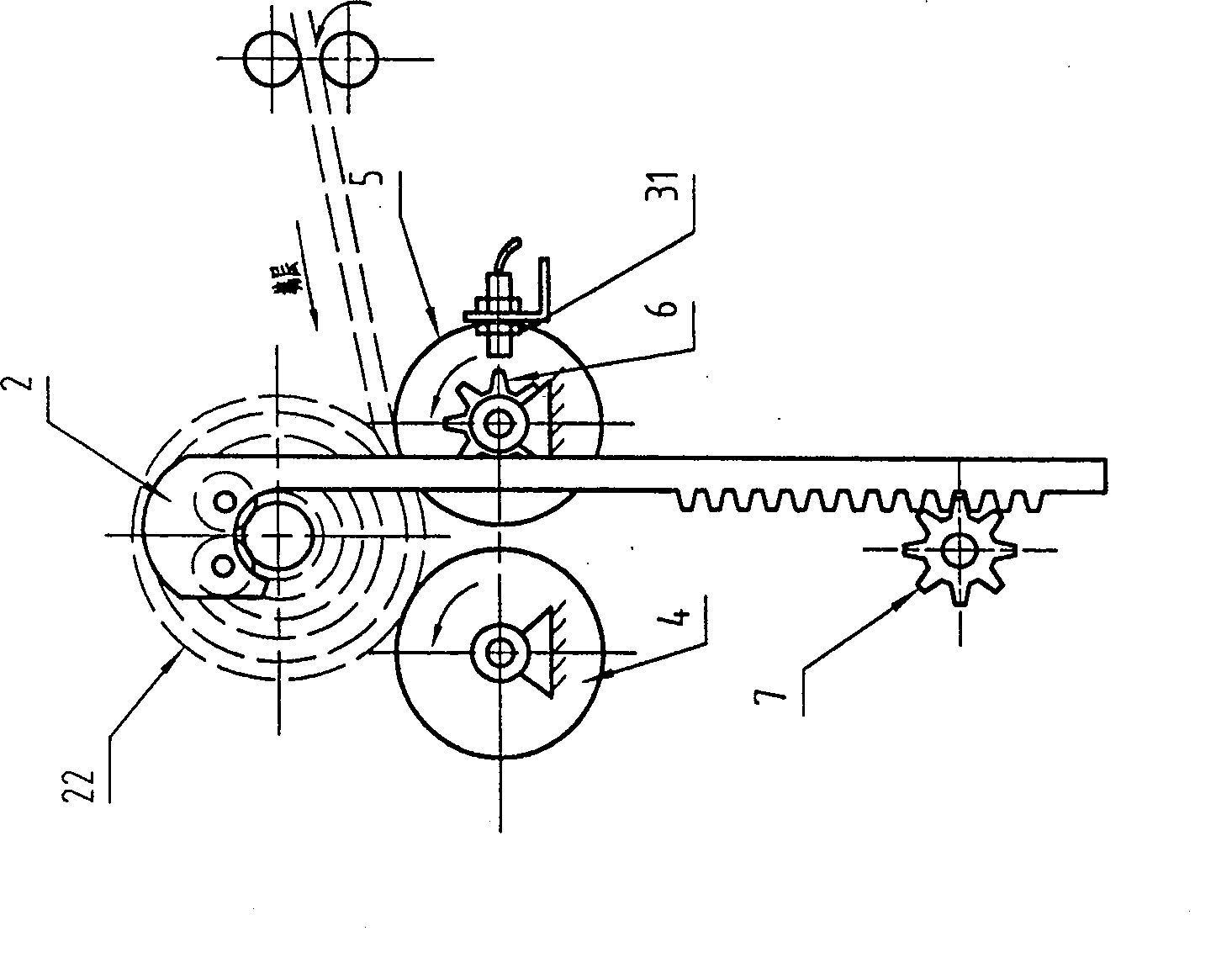

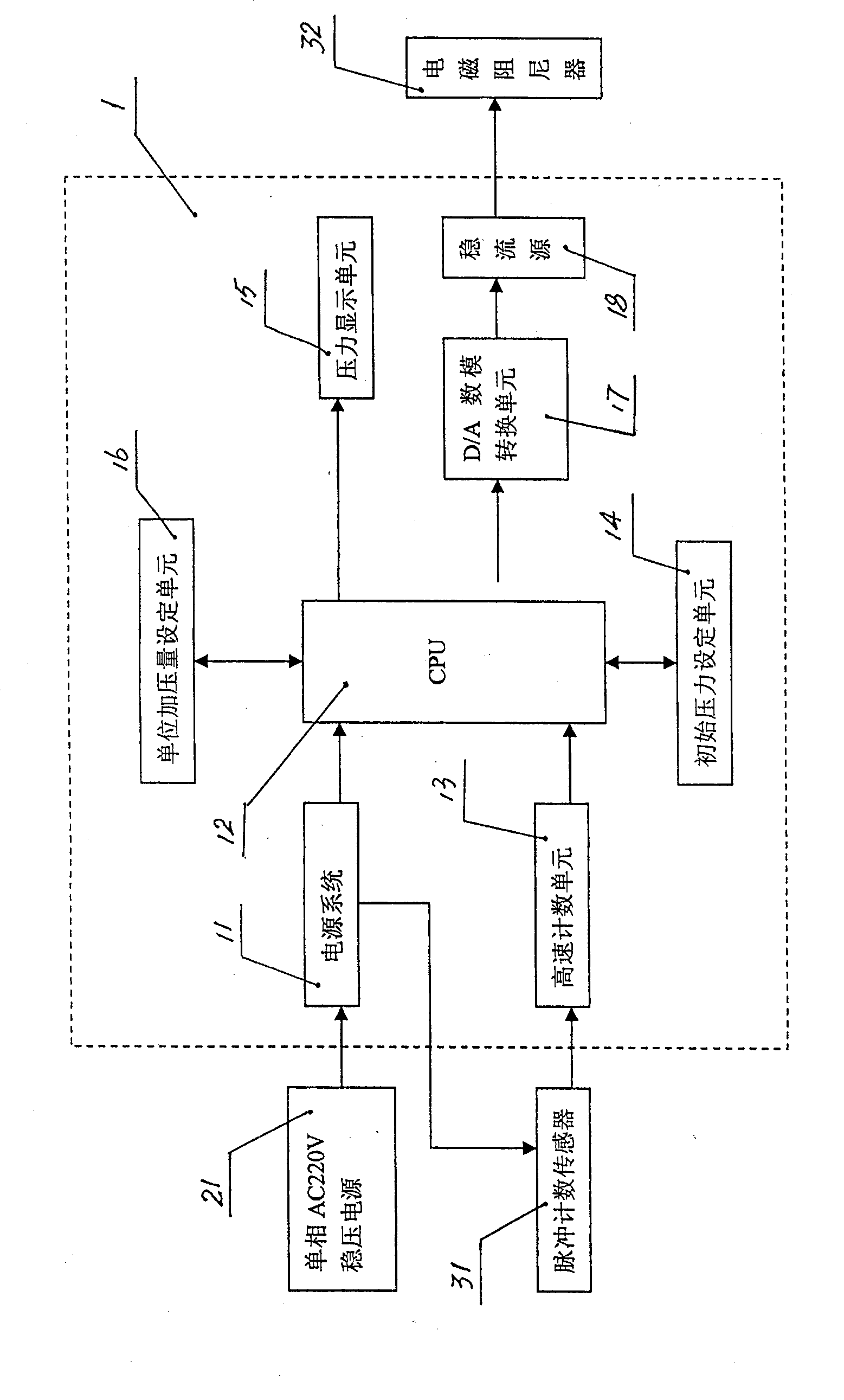

[0013] Depend on figure 1 , figure 2 , image 3 It can be seen that the equal-length and gradually increasing pressure mechanism of the lap according to the present invention is composed of the lap 22, the lap press hook 2, the lap roller 3, the front lap roller 4, the rear lap roller 5, the detection disc 6, and the gear 7 , a pressurized transmission shaft 8, a pulley 9, a motor 10, a pulse counting sensor 31, an electromagnetic damper 32, a control device, etc., the two gears 7 and the electromagnetic damper 30 are fixedly installed on the pressurized transmission shaft 8, and the gear 7 It meshes with the rack on the lap press hook 2, the front lap roller 4 and the rear lap roller 5 are in contact with the lap 22, and the detection disc 6 is installed on the rear lap roller 5 or on the front lap roller 4 , eight signal collection poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com