Method for processing vinyl acetate-ethylene copolymerization emulsions wastewater

A technology of ethylene copolymer emulsion and vinyl acetate, which is applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of large dosage of coagulant and large amount of scum , Unsatisfactory treatment effect and other problems, to achieve stable and reliable treatment effect, simple operation, good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

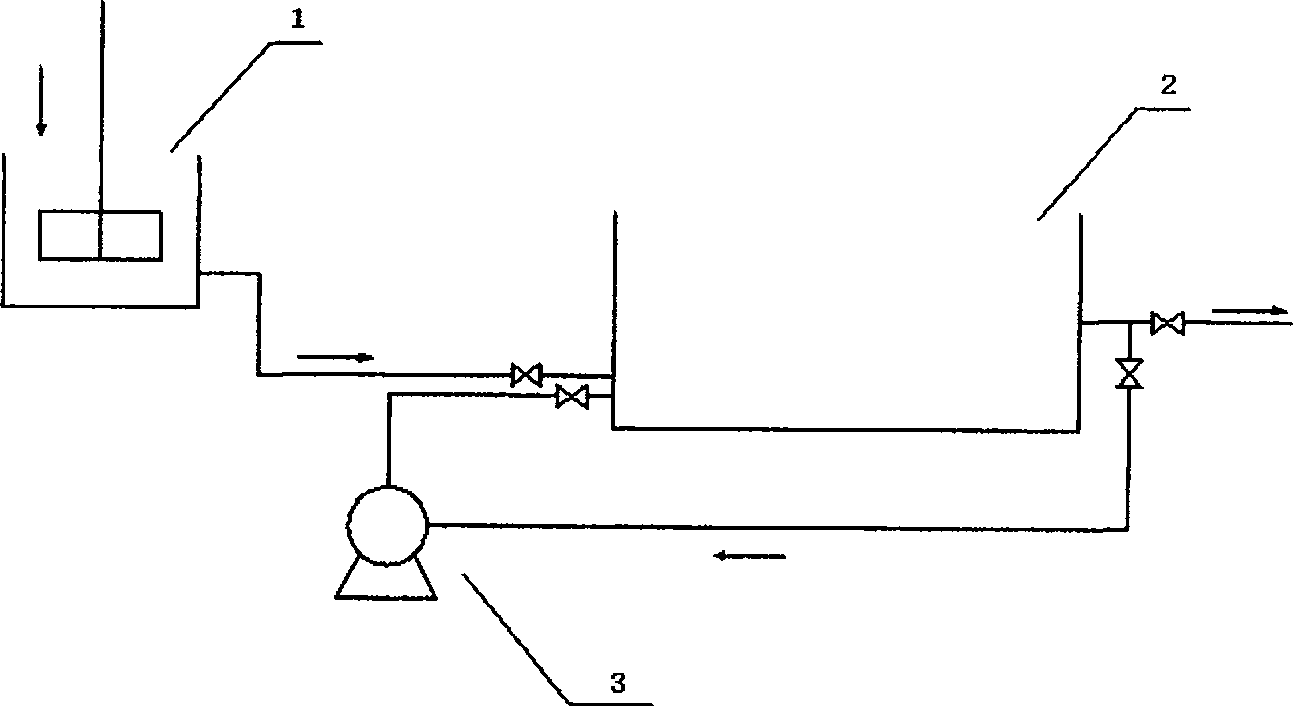

Image

Examples

Embodiment 1

[0023] In this example, the COD of raw water is 3085 mg / L, the turbidity is 2635 NTU, and the pH value is 7.28. Under the condition of G value of 215s-1, add compound high-efficiency coagulant (see attached table 1) 125mg / L, add cationic polyacrylamide 1.5mg / l after 25s, and stir for 8min; control the air flotation device The air flotation pressure is 0.3MPa, and the reflux ratio is 50%. The mixing time of coagulation effluent and dissolved air water is 10min. The effluent water quality indicators are tested, and the COD is reduced to 55.28mg / L, and the turbidity is reduced to 6.0NTU. The equipment is running well and the effluent water quality is stable.

Embodiment 2

[0025] In this example, the COD of raw water is 3612 mg / L, the turbidity is 3210 NTU, and the pH value is 7.18. Under the condition that the G value is 215s-1, add 225mg / L of compound high-efficiency coagulant (see attached table 1 for the composition), add 2.5mg / l of cationic polyacrylamide after 30s, and stir for 8 minutes; control the air flotation device The air flotation pressure is 0.35MPa, and the reflux ratio is 50%. The mixing time of coagulation effluent and dissolved air water is 10min. The effluent water quality indicators are tested, and the COD is reduced to 55.30mg / L, and the turbidity is reduced to 5.5NTU. The equipment is running well and the effluent water quality is stable.

Embodiment 3

[0027] In this embodiment, the COD of the raw water is 4906 mg / L, the turbidity is 4510 NTU, and the pH value is 7.10. Under the condition of G value of 258s-1, add compound high-efficiency coagulant (see attached table 1) 300mg / L, add cationic polyacrylamide 3.2mg / l after 30s, and stir for 10min; control the air flotation device The air flotation pressure is 0.4MPa, and the reflux ratio is 50%. The mixing time of coagulation effluent and dissolved air water is 10min. The effluent water quality indicators are tested, and the COD is reduced to 55.36mg / L, and the turbidity is reduced to 6.5NTU. The equipment is running well and the effluent water quality is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com