Method for preparing decoloring material of dyeing waste water by attapulgite ore

A technology for printing and dyeing wastewater and attapulgite, which is applied in separation methods, chemical instruments and methods, and textile industry wastewater treatment, etc., can solve the problems of low mechanical strength and blister strength of granular materials, high equipment corrosion, and poor recyclability. Excellent decolorization performance, eliminate pollution, reduce the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Attapulgite clay 100kg, 80 mesh, and H concentration of 1.5mol / L 2 SO 4 The solid-liquid ratio is 1:2.5 mixed, activated at room temperature for 2h, and then neutralized with 5mol / L NaOH to a pH of about 7.5, a solid-liquid separation, granulation into 3~5mm granules, drying at 90℃, and then After calcination at 700°C for 1 hour, 85kg of decolorizing material for printing and dyeing wastewater can be obtained. Evaporate and concentrate the filtrate and crystallize to obtain Na 2 SO 4 ·10H 2 O by-product is about 70kg, and the mother liquor is recycled.

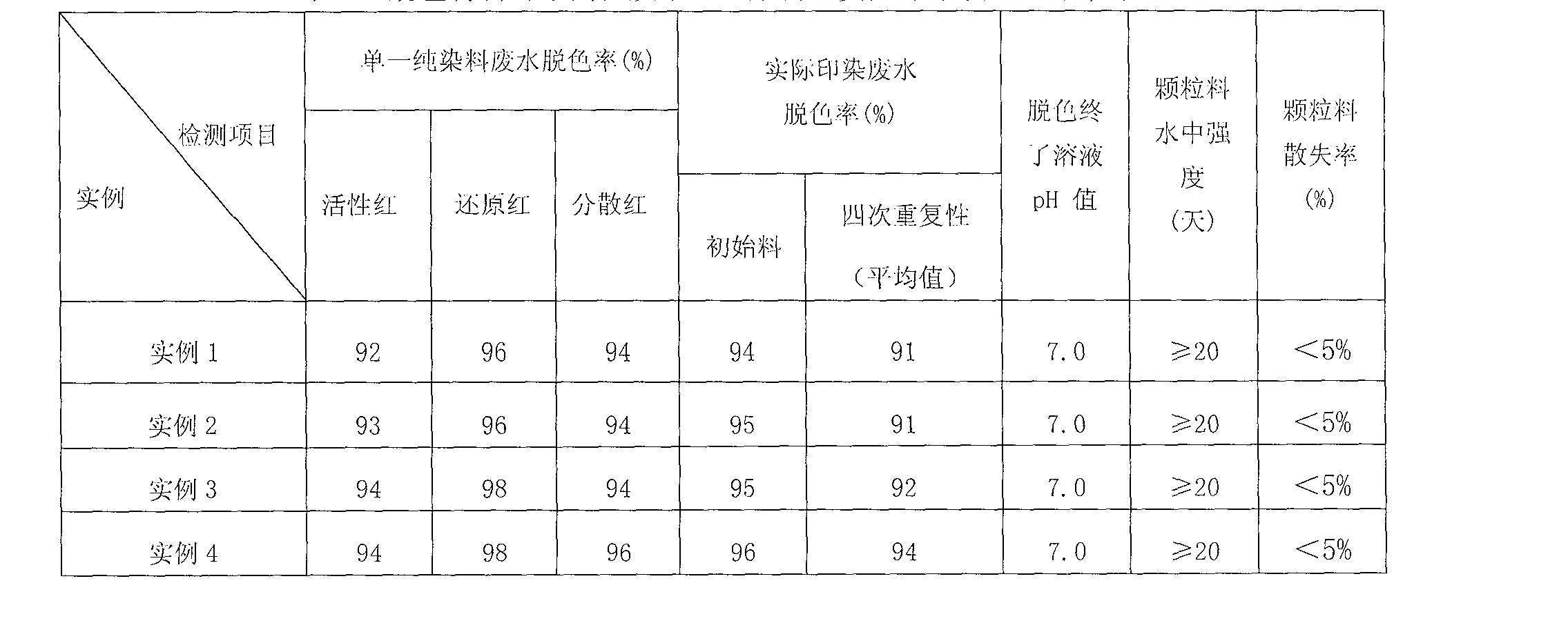

[0022] The decolorizing material after decolorization is soaked in a 5mol / L ammonium sulfate solution for 3 minutes and then calcined at 300°C for 5 minutes, which can be reused. The particle strength of the decolorizing material and its decolorizing effect on single pure dyes with different properties and actual printing and dyeing wastewater are shown in Table 1.

example 2

[0024] Attapulgite clay 100kg, 80 mesh, and H concentration of 2.0mol / L 2 SO 4 Mix with solid-liquid ratio of 1:2.0, activate at room temperature for 2h, then neutralize to pH 7.5 with 5mol / L NaOH, separate solid-liquid once, granulate into 3~5mm pellets, dry at 90℃, and then After calcination at 700°C for 1 hour, 90kg of decolorizing material for printing and dyeing wastewater can be obtained. Evaporate and concentrate the filtrate and crystallize to obtain Na 2 SO 4 ·10H 2 O by-product is about 70kg, and the mother liquor is recycled.

[0025]The decolorizing material after decolorization is soaked in a 3mol / L ammonium sulfate solution for 3 minutes and then calcined at 300°C for 5 minutes, which can be reused. The particle strength of the decolorizing material and its decolorizing effect on single pure dyes with different properties and actual printing and dyeing wastewater are shown in Table 1.

example 3

[0027] Attapulgite clay 100kg, 100 mesh, and H concentration of 1.5mol / L 2 SO 4 Use a solid-liquid ratio of 1:2.0 to mix, activate at room temperature for 1.5h and add 5kg of ferrous sulfate, and then neutralize with 5mol / L NaOH to a pH of about 7.5, a solid-liquid separation, and granulate into 3~5mm pellets. After drying at 90°C and calcining at 700°C for 1 hour, 90kg of decolorizing material for printing and dyeing wastewater can be obtained. Evaporate and concentrate the filtrate and crystallize and separate the produced filtrate to obtain Na 2 SO 4 ·10H 2 The O by-product is about 80kg, and the mother liquor is recycled.

[0028] The decolorizing material after decolorization is soaked in a 2mol / L ammonium sulfate solution for 3 minutes and then calcined at 300°C for 5 minutes, which can be reused. The particle strength of the decolorizing material and its decolorizing effect on single pure dyes with different properties and actual printing and dyeing wastewater are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| acid concentration | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com