Method for producing decoloring material of printing and dyeing waste water

A manufacturing method, printing and dyeing wastewater technology, applied in the direction of adsorption water/sewage treatment, ion exchange water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., to achieve excellent chemical comprehensive decolorization ability, avoid complexity, and reduce production volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

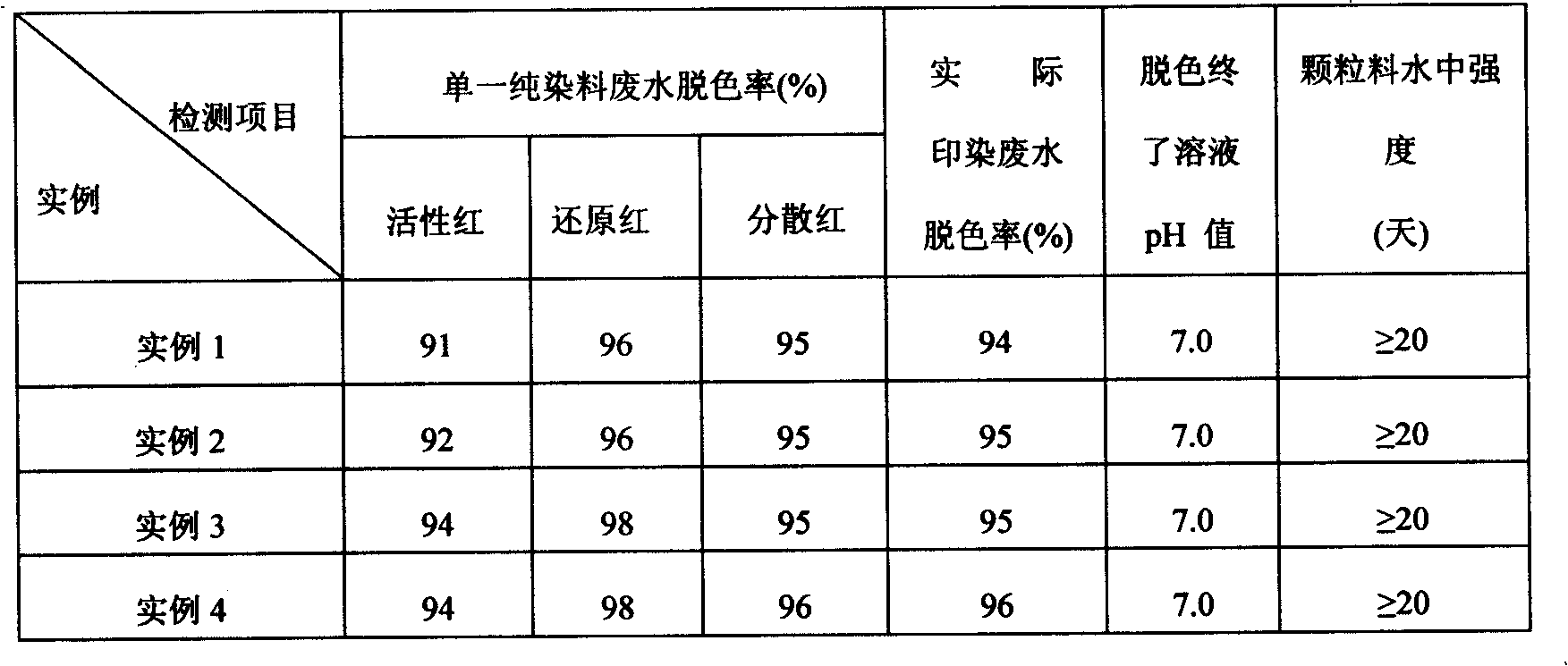

example 1

[0018] Hangjin 2# clay 100kg, coarsely crushed to more than 80 mesh, mixed with H at a concentration of 1.0mol / L 2 SO 4 Use a solid-liquid ratio of 1:3, activate at 95°C for 2 hours, then neutralize with 5mol / L NaOH to a pH value of about 7.5, separate the solid and liquid once, granulate into 3-5mm pellets, dry at 90°C, and then After calcining at 750°C for 3 hours, 85kg of printing and dyeing wastewater decolorization materials can be obtained. The produced filtrate is evaporated and concentrated, crystallized and separated to obtain Na 2 SO 4 10H 2 The O by-product is about 70kg, and the mother liquor is recycled. The particle strength of the decolorizing material and its decolorizing effect on a single pure dye with different properties and actual printing and dyeing wastewater are shown in Table 1.

example 2

[0020] Hangjin 2# clay 100kg, coarsely crushed to more than 80 mesh, mixed with H at a concentration of 1.5mol / L 2 SO 4 Use a solid-liquid ratio of 1:2.5, activate at 95°C for 2 hours, then neutralize with 5mol / L NaOH to a pH value of about 7.5, separate solid-liquid once, granulate into 3-5mm pellets, dry at 90°C, and then After calcining at 750°C for 3 hours, 90kg of printing and dyeing wastewater decolorization materials can be obtained. The produced filtrate is evaporated and concentrated, crystallized and separated to obtain Na 2 SO 4 10H 2 O by-product about 80kg, mother liquor recycling. The particle strength of the decolorizing material and its decolorizing effect on a single pure dye with different properties and actual printing and dyeing wastewater are shown in Table 1.

example 3

[0022] 100kg of Hangjin 2# clay, coarsely crushed to above 40 mesh, mixed with H at a concentration of 2.0mol / L 2 SO 4 Mix with a solid-liquid ratio of 1:2.0, activate at 90°C for 1.5h, then neutralize with 5mol / L NaOH to a pH value of about 7.5, separate solid-liquid once, granulate into 3-5mm pellets, and dry at 90°C. After calcining at 750°C for 3 hours, 90kg of printing and dyeing wastewater decolorization materials can be obtained. The produced filtrate is evaporated and concentrated, crystallized and separated to obtain Na 2 SO 4 10H 2 O by-product about 80kg, mother liquor recycling. The particle strength of the decolorizing material and its decolorizing effect on a single pure dye with different properties and actual printing and dyeing wastewater are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com