Double vertical module forge hammer

A technology of die forging hammer and vertical mold, which is applied in the direction of forging/pressing/hammer device, drop hammer, forging/pressing/hammering machinery, etc. It can solve the problems of large movement gap of hammer head, large energy consumption, waste of water resources, etc. , to achieve low construction and use costs, increase operational safety performance, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

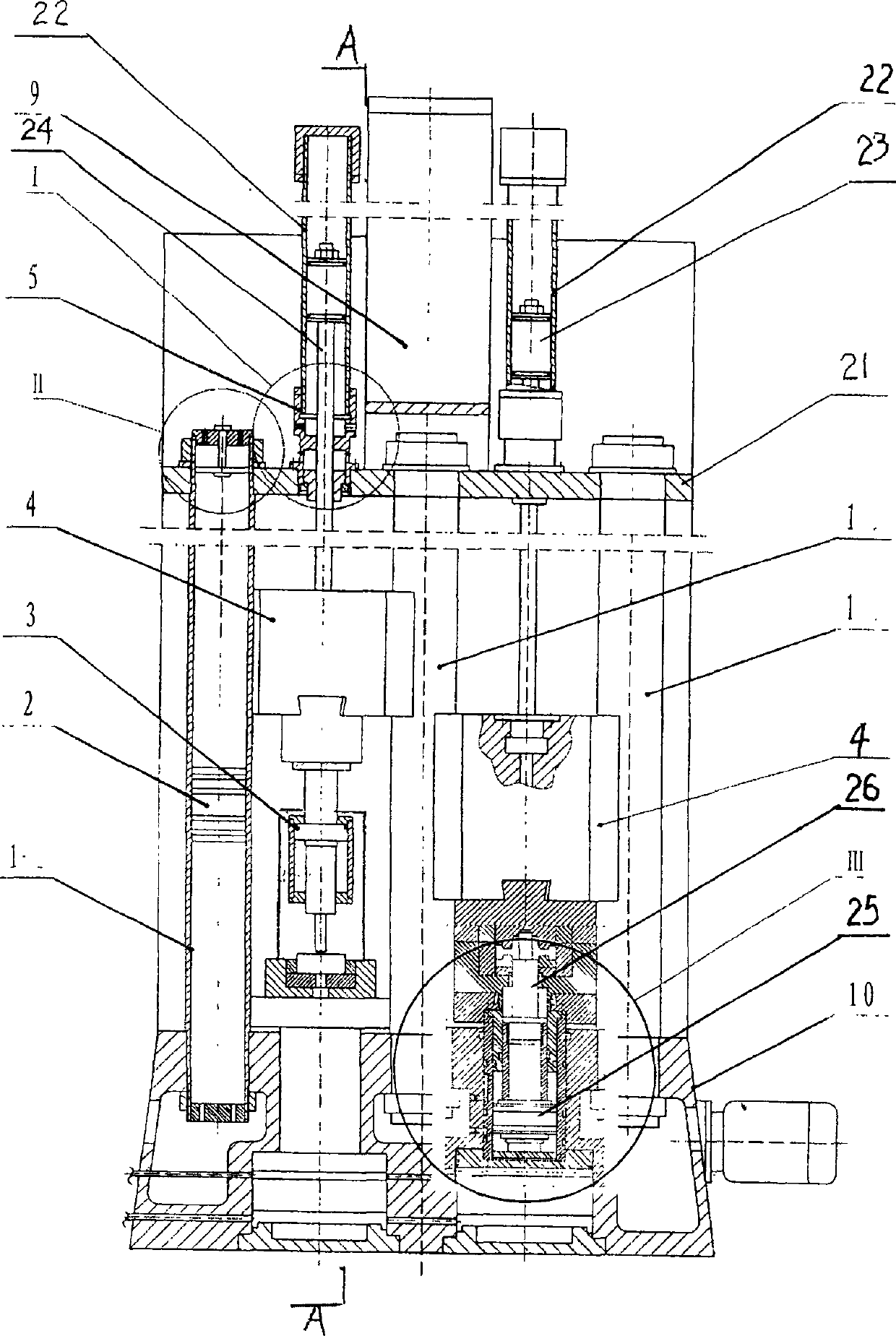

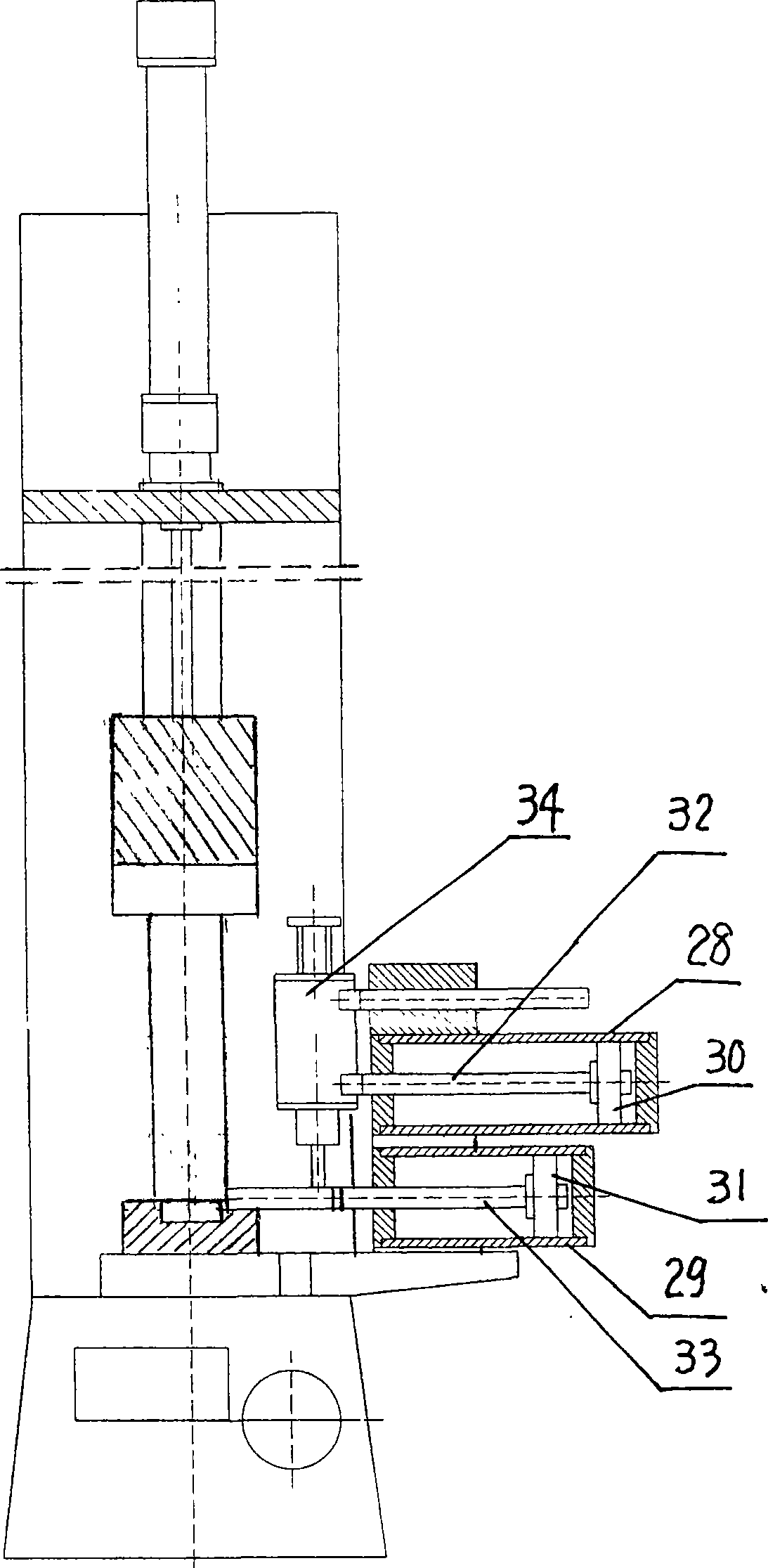

[0023] Combined with Figure 1-3, the composition of die forging hammer includes die forging hammer head, die forging hammer body and die forging hammer base. The die forging hammer head is installed on the upper beam 21, and consists of the die forging hammer head shell 5, the power head cylinder 22 installed on the die forging hammer head shell, the piston 23 arranged in the power head cylinder, and the piston rod connected to the piston. 24 and the storage cylinder 9 that is installed on the upper crossbeam form. The die forging hammer body 4 is installed on the cylinder rod of the die forging hammer head, and the die forging hammer body is equipped with a mold 3 . The upper beam and the die forging hammer base are connected by a column 1. The column is a liner-type column, and an oil-gas separation piston 2 is arranged in the column. The upper end of the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com