A canal step channel unit transistor and its manufacture method

A manufacturing method and technology of transistors, which can be used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., and can solve problems such as leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

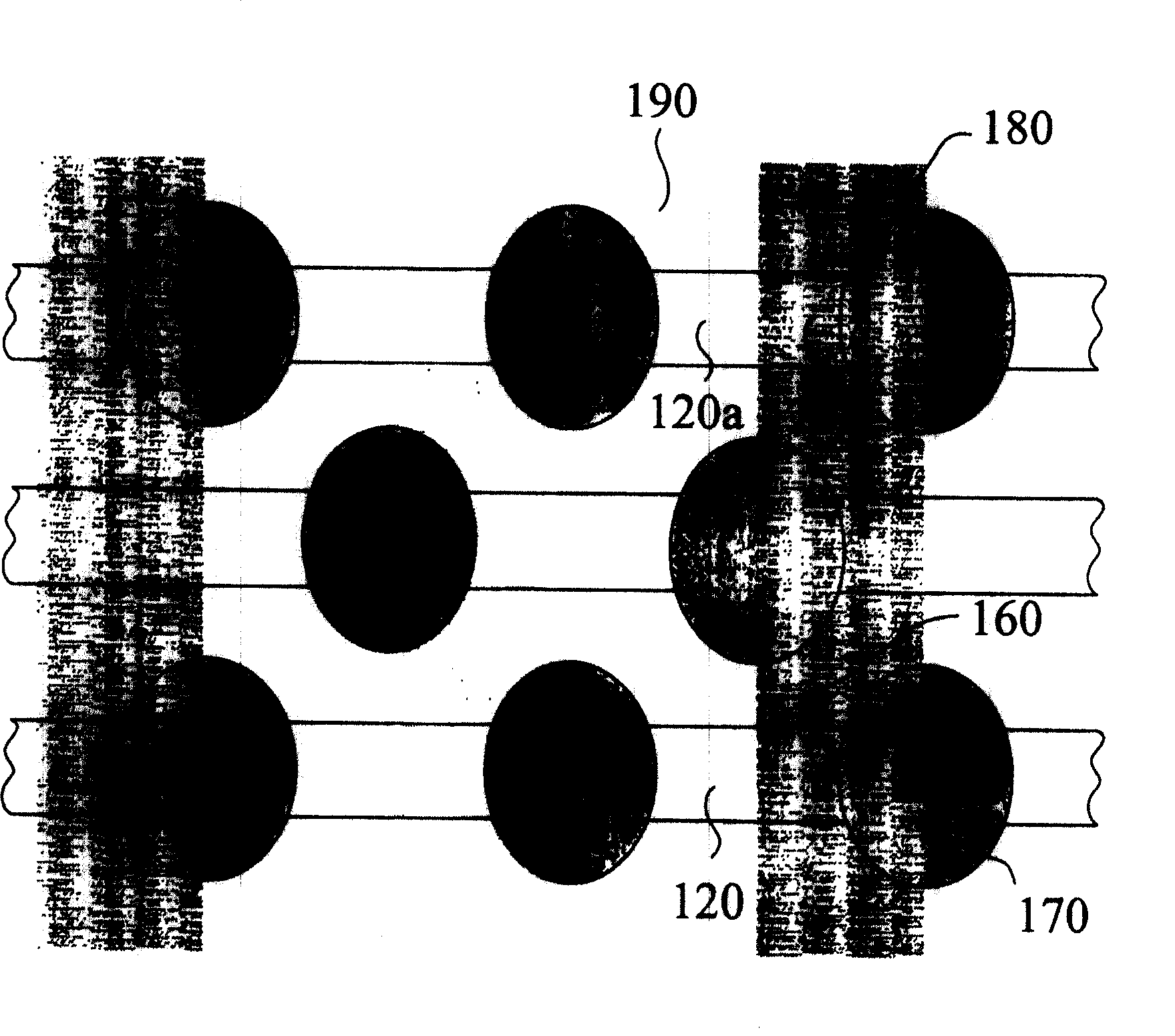

[0057] figure 1 A trench step channel unit transistor applying the technology of the present invention is shown, and the figure shows a schematic diagram of the relative positions of the components of the present invention. The channel of the trench stepped channel transistor of the present invention mainly includes an anisotropic stepped silicon layer 110 and an active element region 120 in the substrate 100, wherein the substrate 100 has a trench capacitor structure, and the capacitor structure includes a deep trench structure 170, The first electrode 260, the insulating layer 270, the second electrode 280, the buried conductor layer 290, and the like.

[0058] Secondly, in terms of position setting, the anisotropic step silicon layer 110 is located above the active element region 120, the deep trench structure 170 is located in the substrate 100, and the first electrode 260 is located in the substrate 100 and surrounds the lower edge of the deep trench structure 170 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com