Piezoelectric ceramic composition and piezoelectric element

A technology of piezoelectric ceramics and piezoelectric components, which is applied to electrical components, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. High numerical value and other problems, to achieve the effect of excellent piezoelectric characteristics and good electromechanical bonding coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

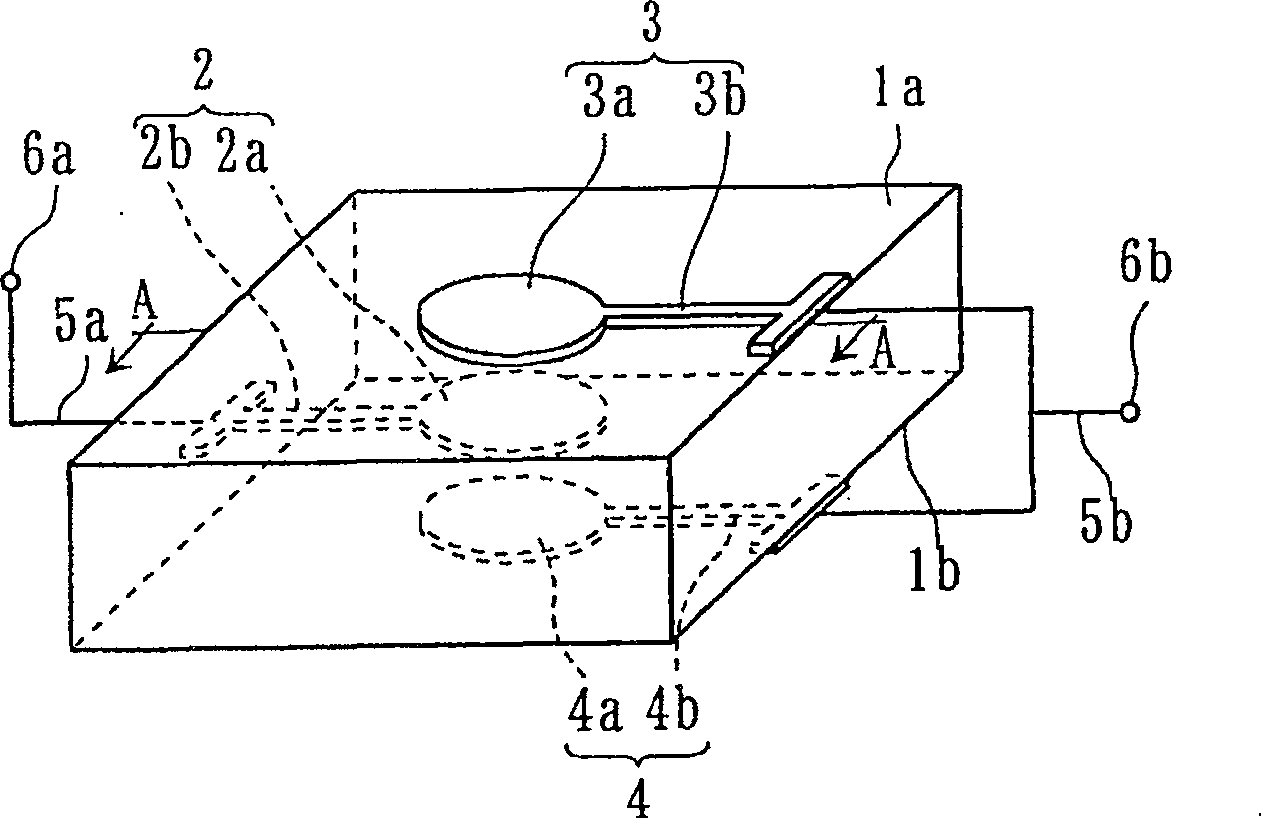

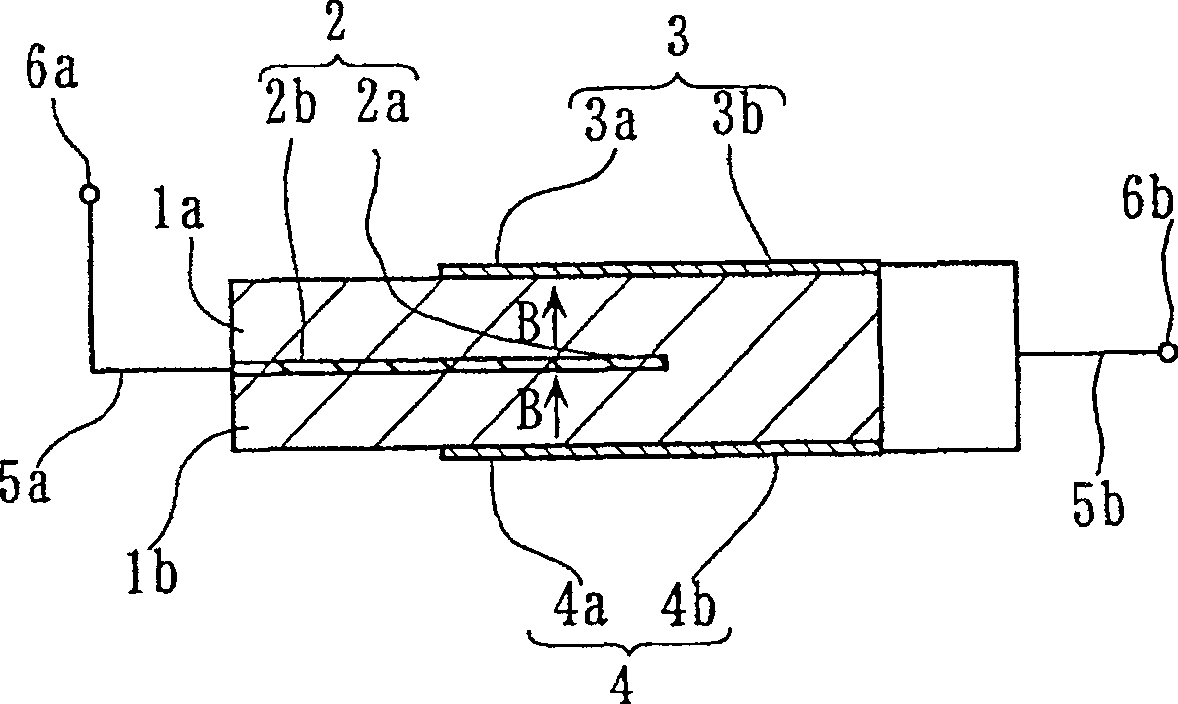

Image

Examples

Embodiment 1

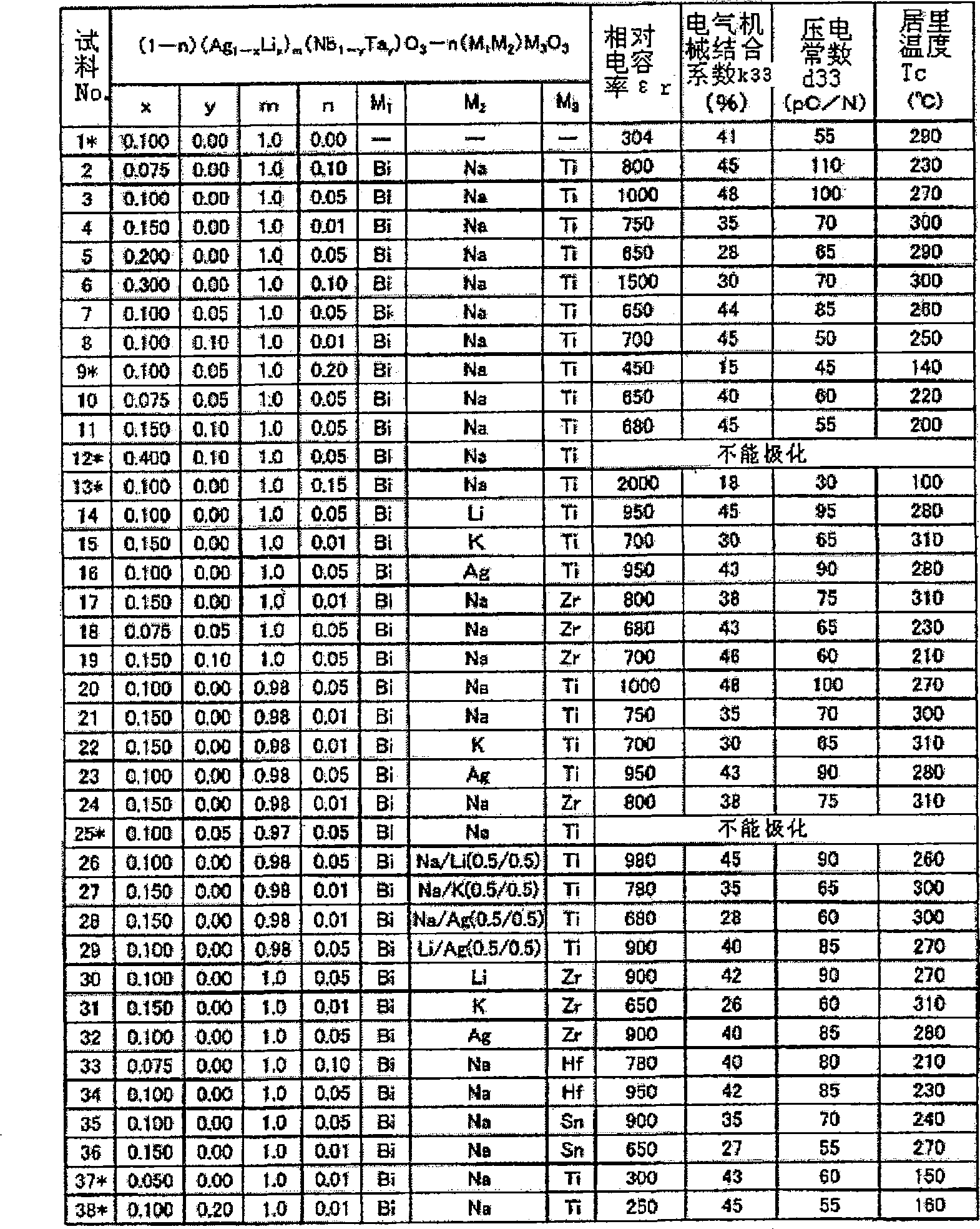

[0093] First, weigh the following powders according to the composition of Table 1: Ag 2 O. Li 2 CO 3 , Nb 2 o 5 、 Ta 2 o 5 、 Bi 2 o 3 、Na 2 CO 3 、K 2 CO 3 、TiO 2 , ZrO 2 , SnO 2 , HfO 2 , using an electric furnace in an oxidative atmosphere at a temperature of 850° C. to 1100° C. for 10 hours of pre-calcination treatment to obtain pre-calcined objects.

[0094] Next, after performing wet pulverization treatment on this precalcined product, the polyvinyl alcohol resin as a binder is 5 parts by weight with respect to 100 parts by weight of the calcined product, and the precalcined product and the polyvinyl alcohol resin are mixed in this manner. , followed by drying, using a single-screw extruder to 9.8×10 8 The pressure of Pa is pressed to form a prism shape of 12 mm in length, 12 mm in width, and 2.5 mm in thickness, and then fired at 950°C to 1200°C for 3 to 10 hours in an oxidizing atmosphere to produce piezoelectric ceramics.

[0095] Next, Ag paste was app...

Embodiment 2

[0113] Weigh the following powders according to the composition of Table 2: Ag 2 O. Li 2 CO 3 , Nb 2 o 5 、 Ta 2 o 5 、BaO 3 , SrCO 3 , CaCO 3 , MgO, TiO 2 , ZrO 2 , SnO 2 , HfO 2 , using an electric furnace under an oxidizing atmosphere to perform pre-calcination treatment on each weighing object at a temperature of 800° C. to 1100° C. for 10 hours to obtain a pre-calcined object.

[0114] Thereafter, piezoelectric elements of sample numbers 41 to 80 were obtained by the same method and procedure as in Example 1.

[0115] Next, according to the same method and procedure as in Example 1, the relative permittivity εr and the electromechanical connection coefficient K under thickness vibration were carried out for the piezoelectric elements of sample numbers 41 to 80 33 , piezoelectric constant d under thickness vibration 33 , and the determination of the Curie temperature Tc.

[0116] Table 2 shows the components and measurement results of sample numbers 41 to 80. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com