Device for conveying printing material in a machine, conveyor system therein and manufacture method

A transmission system and printing material technology, applied in the field of transmission systems, can solve the problems of low-adjustment dynamic performance, etc., and achieve the effects of high switching dynamic performance, precise mechanical guidance, and fast switching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

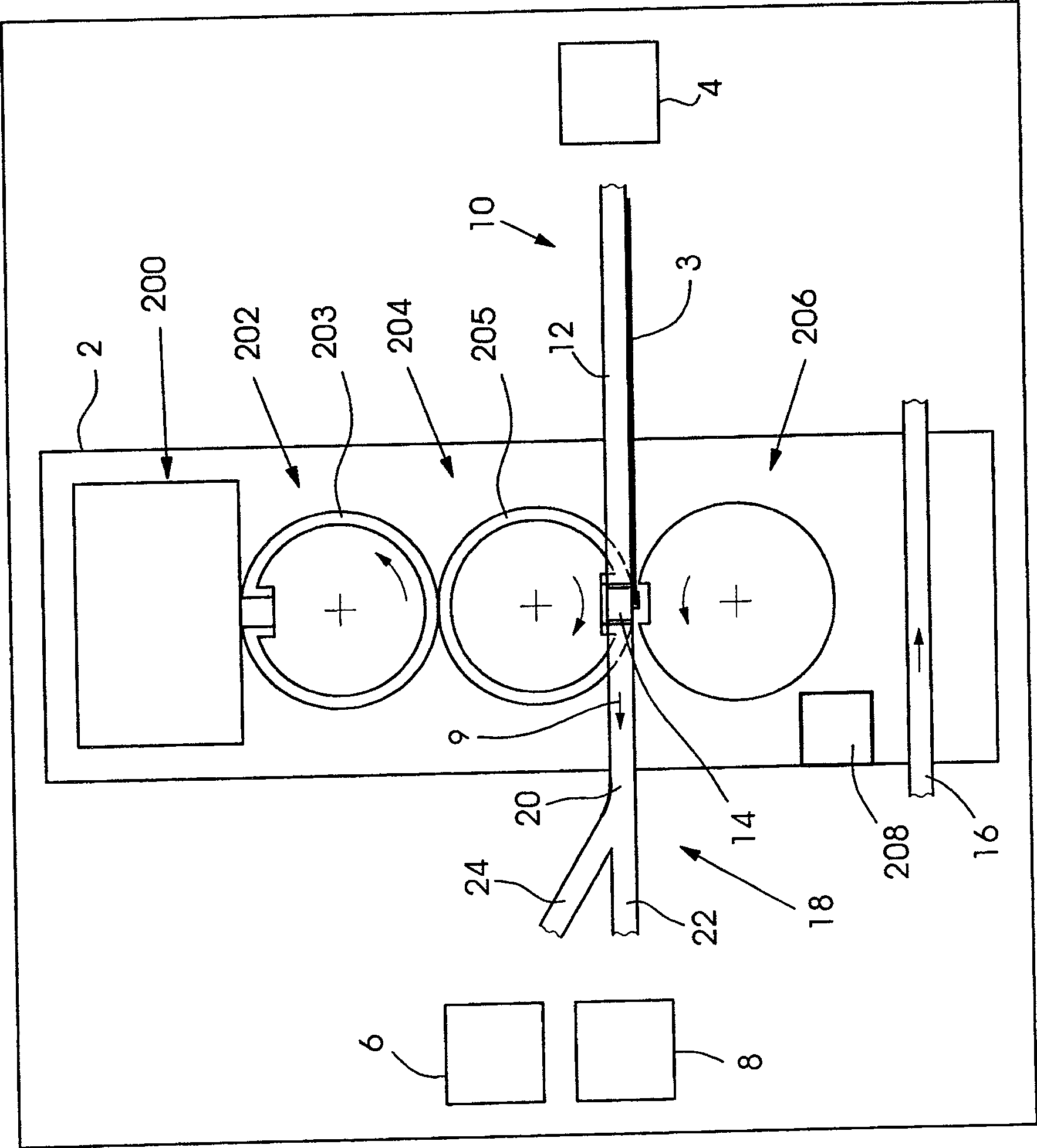

[0074] figure 1 A schematic side view of a printing unit 2 of a printing press 1 that processes printing materials 3 , for example in the form of printed sheets, is shown. At least one unit 4 is provided in front of the printing unit 2, such as an additional printing unit or a sheet feeder, and at least two units 6, 8 are provided behind the printing unit, such as additional printing units, Coating units, dryers, sheet receivers or finishing units (such as cutters, folders, punchers, binders or packaging stations).

[0075] The printing unit has an inking and / or dampening unit 200 with rollers, a printing plate cylinder with a tensioned printing plate 203 (for example a printing plate or a printing sleeve), a tensioned transfer cloth 205 (such as a blanket or blanket cover) transfer roller 204 and a counterpress roller 206. Furthermore, the printing unit 2 can also have a separate electric motor 208 for driving the cylinders and rollers, or the printing unit can be driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com