Composite damping sheets

A composite damping and sheet technology, applied in the fields of construction, transportation, machinery and equipment, can solve the problems of flow deformation, aging, cold flow, etc., and achieve the effect of high damping, low price and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

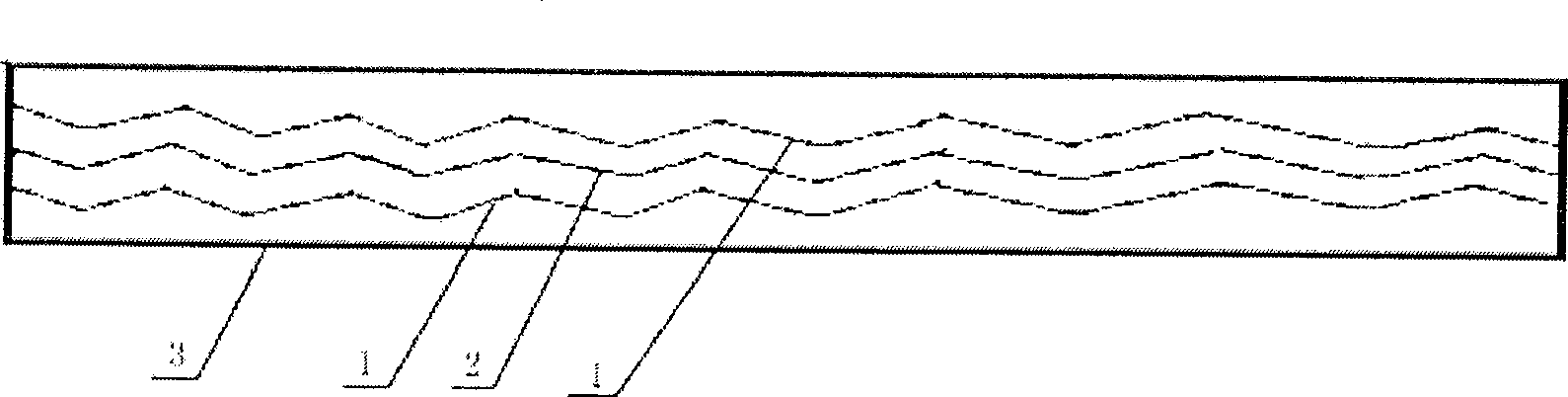

[0014] Embodiment one, with reference to the attached figure 1 , a composite damping sheet, comprising a damping layer 1, the damping layer is sandwiched with at least one fiber reinforced layer 2, the outer surface of the damping layer is covered with a film layer 3, and the damping material in the damping layer 1 is The blend of asphalt and SBS elastomer, the damping enhancer is mica powder, the fiber reinforced layer material is metal fiber fabric, and the film layer is a fully enclosed plastic film.

Embodiment 2

[0015] Embodiment 2 Refer to the attached figure 1 , a composite damping sheet, comprising a damping layer 1, the damping layer is sandwiched with at least one fiber reinforced layer 2, the outer surface of the damping layer is covered with a film layer 3, and the damping matrix material in the damping layer 1 It is a blend of asphalt and APP elastomer, the strength enhancer is Dura fiber, the filling material is rubber powder, the fiber reinforced layer material is non-metallic fiber fabric, and the film layer is a fully enclosed metal film.

Embodiment 3

[0016] Embodiment Three Refer to the attached figure 1 , a composite damping sheet, comprising a damping layer 1, the damping layer is sandwiched with at least one fiber reinforced layer 2, the outer surface of the damping layer is covered with a film layer 3, and the damping matrix material is asphalt and SBS elastic In the case of a blend of bodies, the fiber reinforced layer material is polymer fiber fabric, and the film layer is a fully enclosed composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com