High performance dehydrating drier

A dryer and high-efficiency technology, applied in the direction of non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of energy consumption, low output, and increased equipment investment costs, and achieve improved production efficiency, simple structure, Effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

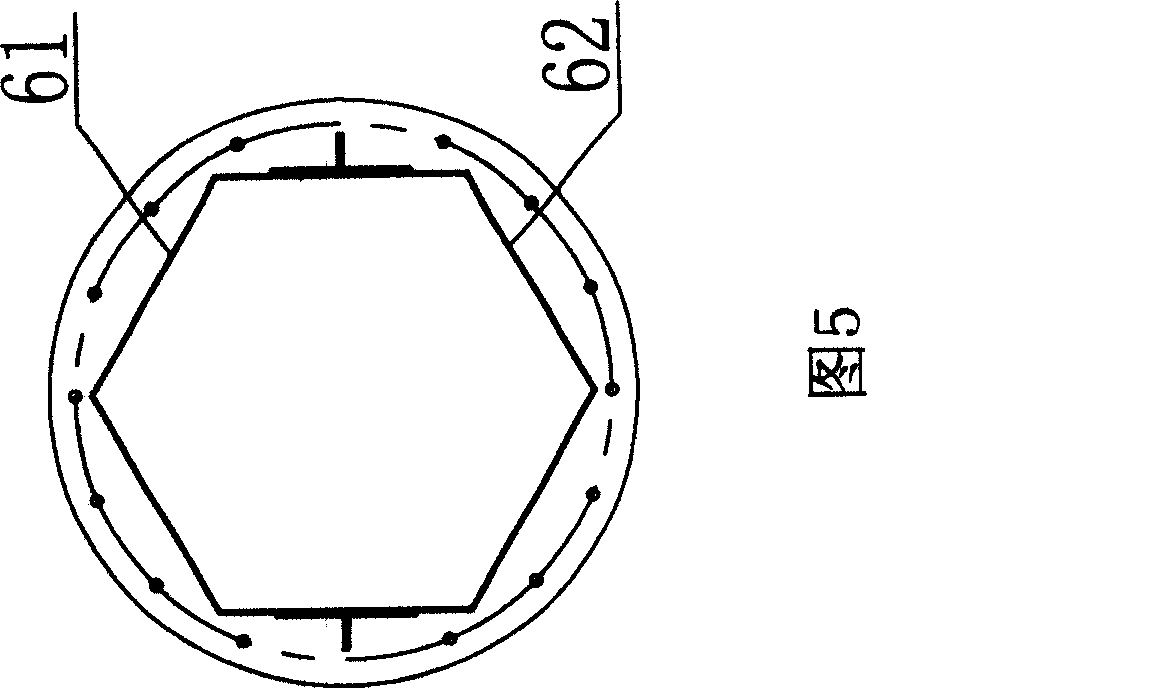

[0020] As shown in Fig. 1 and Fig. 2, in the present embodiment, the high-efficiency dehydration dryer includes: a frame 1, on which is provided a cylindrical shape composed of upper and lower semi-cylindrical bodies 31 and 32. Housing, one side of upper and lower semi-cylindrical bodies 31 and 32 are mutually hinged by hinge 312, and driving oil cylinder 311 is fixedly installed on the frame 1, and the piston rod 313 of driving oil cylinder 311 and the driving arm fixed on the semi-cylindrical body 31 314 is movably connected, and the semi-cylindrical body 31 can be opened or closed by controlling the drive cylinder 311; the bottom of the casing is provided with a water outlet 33, and the main shaft 4 is set in the casing through a pair of bearings 5, and one end of the main shaft 4 is set after extending out of the casing Driven wheel 71 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com