Low-temperature residual heat power generating system for steel smelting sintering ring-cooling machine

A sintered annular cooler and low-temperature waste heat technology, which is used in machinery/engine, waste heat treatment, mechanical equipment, etc., can solve the problems of low power generation output, high steam consumption for power generation, low heat exchange efficiency of heat exchange elements, etc., to improve efficiency. , the effect of improving the power generation capacity of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

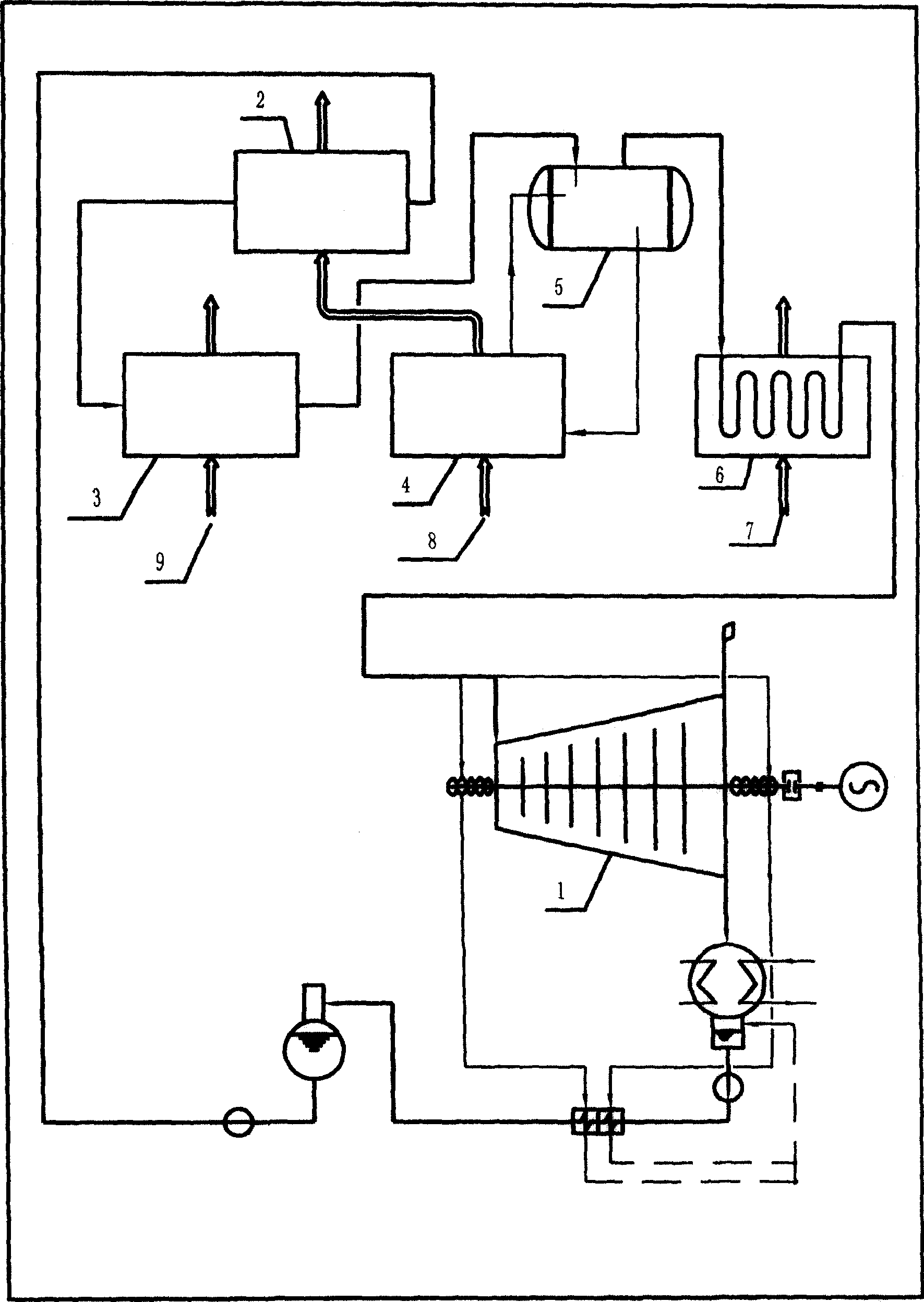

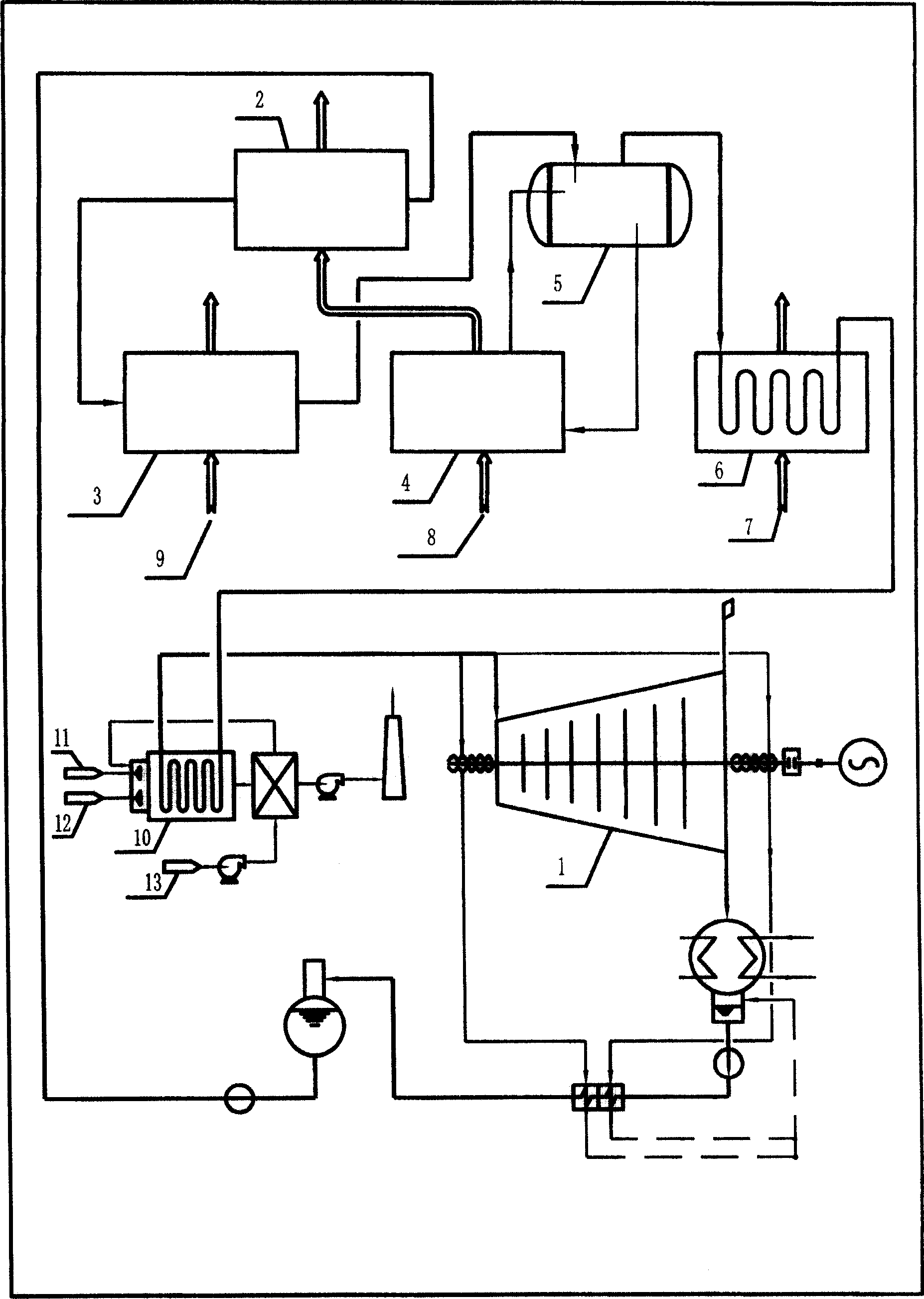

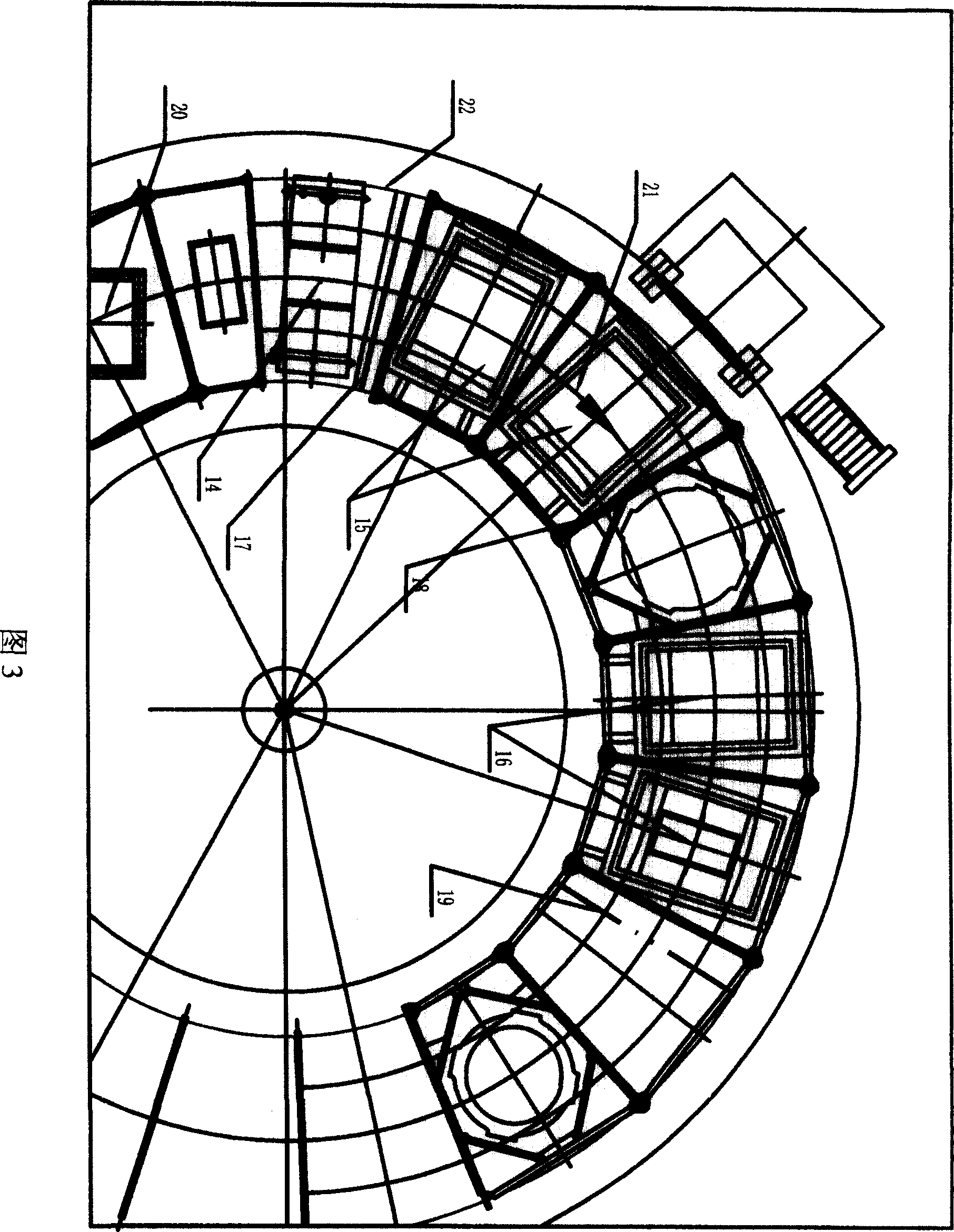

[0017] As shown in Figure 3, during the process of the sintered red ore in the ring cooler from the inlet to the outlet, the ambient air blown in by the blower gradually cools its temperature from about 650°C to below 150°C. After heat exchange Three strands of hot flue gas at 420°C, 370°C and 225°C are generated. Among them, the flue gas at 420°C is discharged into the original electrostatic precipitator system, and the flue gas at 370°C and 225°C is discharged into the atmosphere through the upper chimney of the sintering ring cooler. The solution of the present invention is to utilize flue gas resources in cascades, arrange an evaporator and a first-stage economizer at a medium-temperature heat source at 370°C, arrange a second-stage economizer at a low-temperature heat source at 225°C, and arrange a second-stage economizer at a high-temperature heat source at 420°C. stage superheater. Through heat exchange, the hot flue gas of the annular cooler can produce superheated st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com