High strength aluminium alloy wire and rod and their prepn process

A preparation process, aluminum alloy technology, applied in metal rolling and other directions, can solve problems such as inability to meet high-voltage transmission grids, and achieve the effect of avoiding repeated investment, reducing intermediate links, and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiment of the present invention: high-strength aluminum alloy wire rod, which contains aluminum, iron, magnesium, silicon, copper, zinc, manganese, chromium, boron, titanium elements, the mass percentage of each element is: iron 0.20%, magnesium 0.65% , silicon 0.60%, copper ≤0.10%, zinc ≤0.10%, manganese ≤0.03%, chromium ≤0.03%, boron ≤0.06%, titanium 0.006%, impurity content ≤0.10%, and the rest is aluminum.

[0015] When preparing the above-mentioned high-strength aluminum alloy wire rod, the following steps are included:

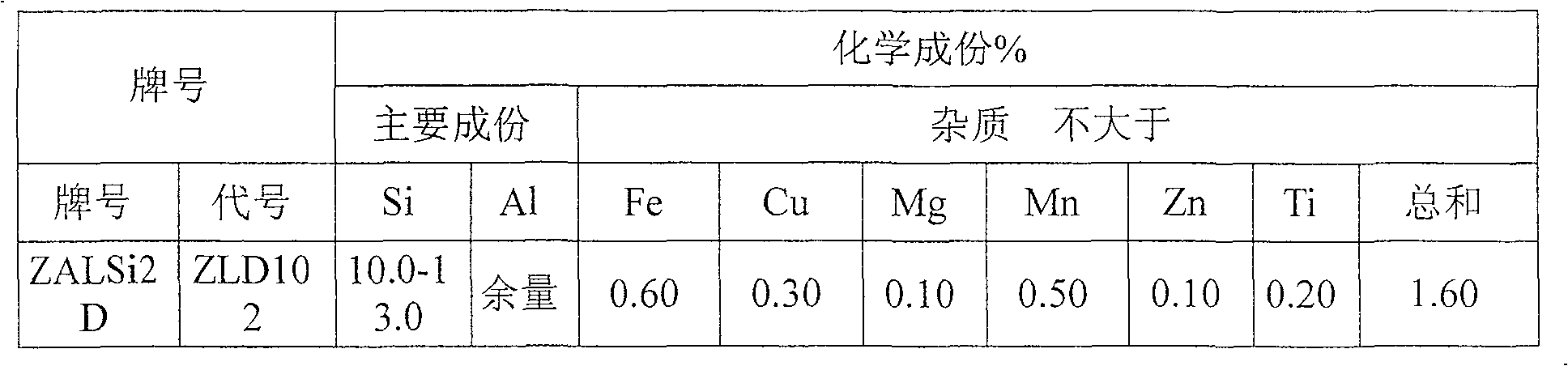

[0016] A. Melting of aluminum alloy: first add 102 intermediate alloy block and metal magnesium ingot into the holding furnace. The quality of 102 alloy should meet the standard requirements of GB / TB733-2000 "ZLD102 Alloy Ingot", and the chemical composition should meet the requirements of the following table:

[0017]

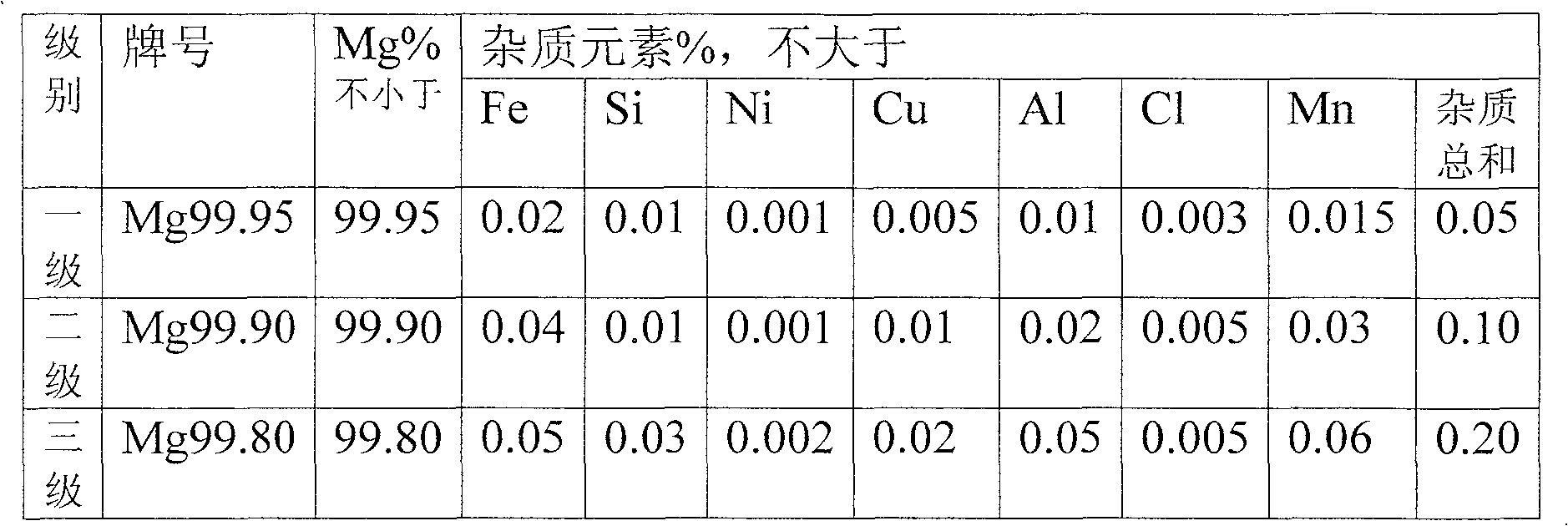

[0018] The quality of metal magnesium ingots should meet the requirements of GB / T3499-83 standard level two or above, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com