Preparation method of microcapsule for electronic paper display

A display and microcapsule technology, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor pressure performance, poor stability, and high cost, and achieve the effect of reducing costs and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

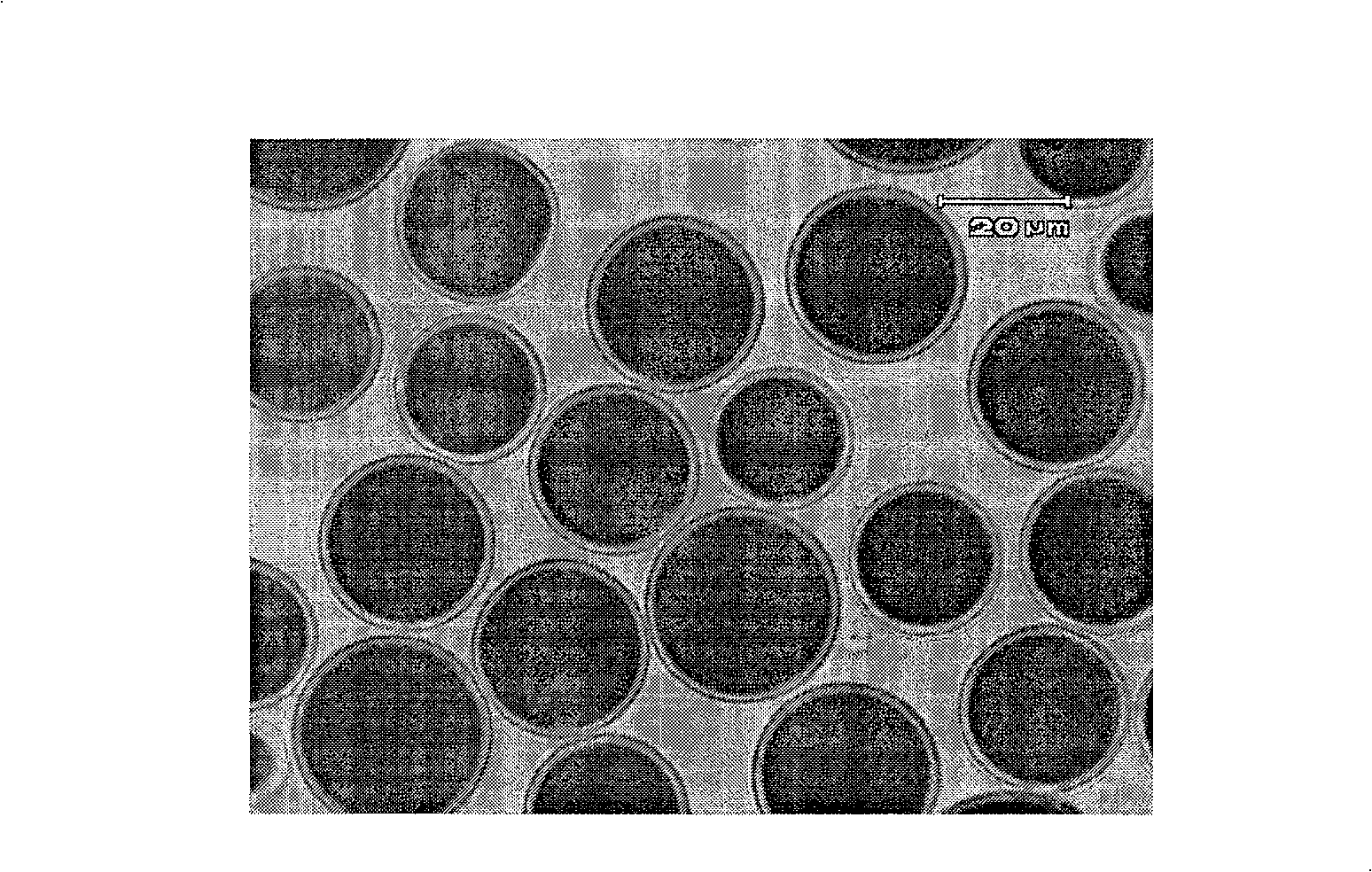

Image

Examples

Embodiment 1

[0019] 1) Dissolving 10 grams of sodium carboxylignin sulfonate and 0.1 gram of sodium hexadecyl sulfonate in water at 80°C to obtain an aqueous solution;

[0020] 2) Add 5 grams of silica particles and 0.5 grams of oil-soluble blue to 300 grams of tetrachlorethylene, and ultrasonically vibrate at 40°C to make it a uniform electrophoretic suspension. Take 70 grams of the electrophoretic suspension and add it to In the above aqueous solution, stir for 20 minutes to obtain an O / W emulsion;

[0021] 3) Dissolve 200 grams of gelatin in water at 50°C to make a 50% aqueous solution, add 20% acetic acid solution, adjust the pH value to 6.5, and add the prepared gelatin aqueous solution to the above O / W emulsion;

[0022] 4) At 50°C, add 20% acetic acid solution to the product of step 3), and adjust the pH value to 4.5;

[0023] 5) During stirring, the temperature of the reaction product in step 4) was reduced to 10°C, and 2.5 milliliters of 37% formaldehyde aqueous solution was adde...

Embodiment 2

[0026] 1) Dissolving 10 grams of polyacrylamide and 1 gram of sodium hexadecylbenzenesulfonate in water at 40°C to obtain an aqueous solution;

[0027] 2) Add 5 grams of silicon dioxide particles and 0.5 grams of oil-soluble black to 200 grams of tetrachlorethylene, and ultrasonically vibrate at 50 ° C to make it a uniform electrophoretic suspension. Take 10 grams of the electrophoretic suspension and add it to In the above aqueous solution, stir for 5 minutes to obtain an O / W emulsion;

[0028] 3) Dissolve 1 gram of gelatin in water at 40°C to make a 1% aqueous solution, add 5% sulfuric acid solution, adjust the pH to 6.0, and add the prepared gelatin aqueous solution to the above-mentioned O / W emulsion;

[0029] 4) At 40°C, add 5% sulfuric acid solution to the product of step 3) to adjust the pH value to 4.0;

[0030] 5) During stirring, the temperature of the reaction product in step 4) was reduced to 0°C, and 4 ml of 15% formaldehyde solution was added to cross-link the w...

Embodiment 3

[0033] 1) Dissolving 1 gram of sodium alginate and 1 gram of sodium α-alkenyl sulfonate in water at 100°C to obtain an aqueous solution;

[0034] 2) Add 10 grams of titanium dioxide particles and 0.5 grams of oil soluble blue to 300 grams of tetrachlorethylene, and ultrasonically vibrate at 70 ° C to make it a uniform electrophoretic suspension. Take 100 grams of the electrophoretic suspension and add it to the above aqueous solution , stirred for 70 minutes to obtain an O / W emulsion;

[0035] 3) Dissolve 10 grams of gelatin in water at 70°C to make a 2% aqueous solution, add 0.05% hydrochloric acid solution, adjust the pH value to 6.2, and add the prepared gelatin aqueous solution to the above O / W emulsion;

[0036] 4) At 40°C, add 0.05% hydrochloric acid solution to the product of step 3) to adjust the pH value to 4.8;

[0037] 5) During stirring, the temperature of the reaction product in step 4) was lowered to 15° C., and 6 ml of 25% formaldehyde solution was added to cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com