Waste gas recirculation heat-exchanger

A waste gas recirculation and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of low heat exchange efficiency and heat exchange effect of heat exchangers that cannot meet the requirements, and achieve Improved heat exchange efficiency, simple structure, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

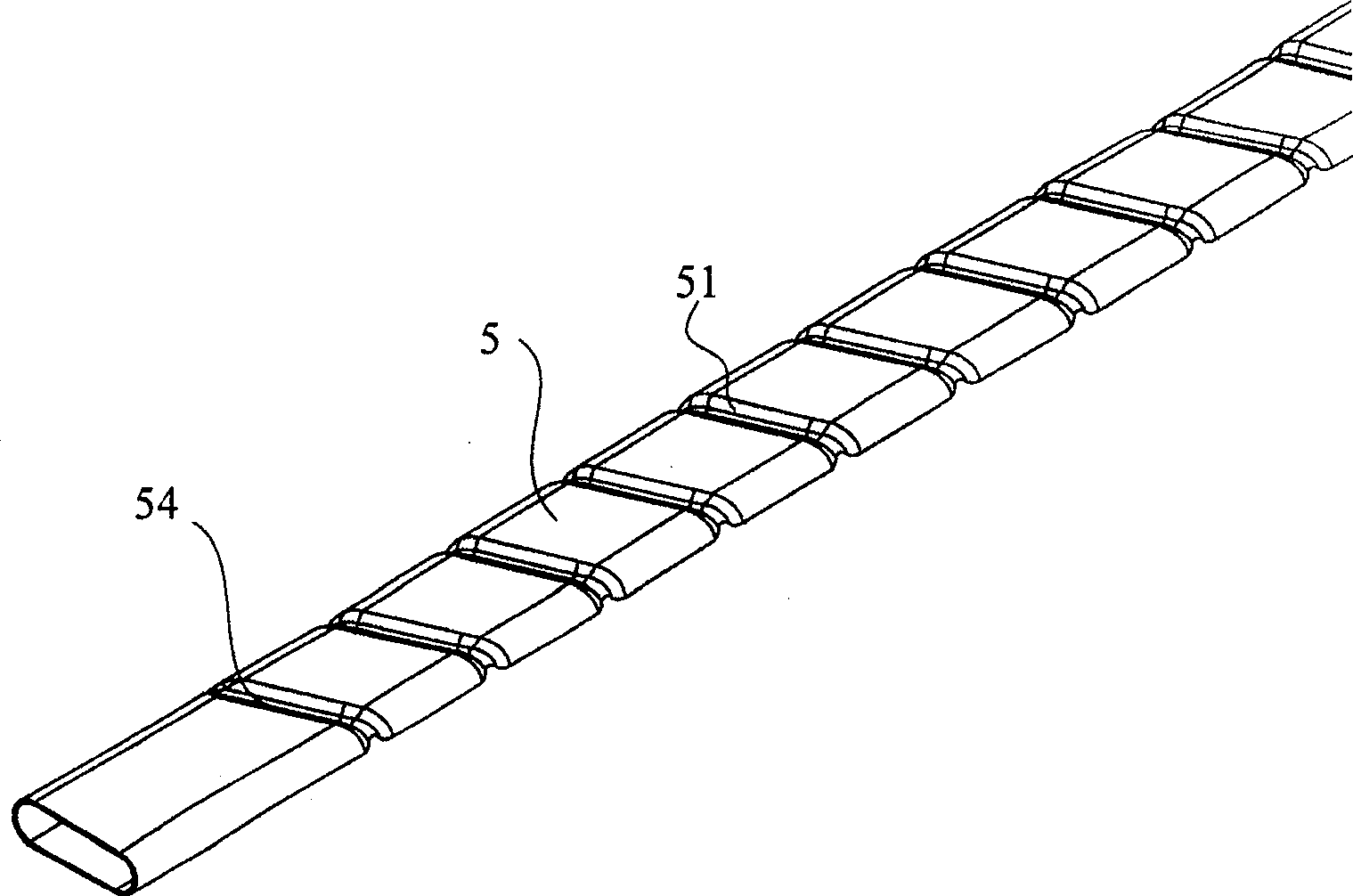

[0046] see Figure 11 , is when the shell 6 of the heat exchanger has a circular cross section, the arrangement of the heat exchange tubes 5 with a flat cross section in the shell 6; the heat exchange tubes 5 are compactly arranged in the shell, and the heat exchanger The arrangement includes sequential arrangement and staggered arrangement, and the heat exchange tubes along the shell are arranged in a ring shape at a certain angle. This arrangement is compact and can improve the heat exchange efficiency of the heat exchanger.

Embodiment 2

[0048] see Figure 12 , when the shell 6 of the heat exchanger has a rectangular cross section, the arrangement of the heat exchange tubes 5 with a rectangular cross section in the shell 6; the heat exchange tubes 5 are staggered at a certain angle, and two adjacent rows of tube bundles are symmetrical Arranged in a distributed manner, the two ends of the nozzles of the heat exchange tubes 5 are welded and fixed on the tube plates 62 at both ends of the shell 6. This arrangement makes the flow of the coolant outside the tubes intensified, thereby increasing the amount of heat exchange.

Embodiment 3

[0050] see Figure 13 , is when the shell 6 of the heat exchanger has a rectangular cross-section, the arrangement of the heat exchange tubes whose cross-sectional shapes are arc-shaped in the shell 6 . The heat exchange tubes 5 are staggeredly arranged in the housing in two ways of vertical and parallel. Such an arrangement increases the turbulence of the coolant outside the tube, which enhances the heat exchange effect inside and outside the tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com