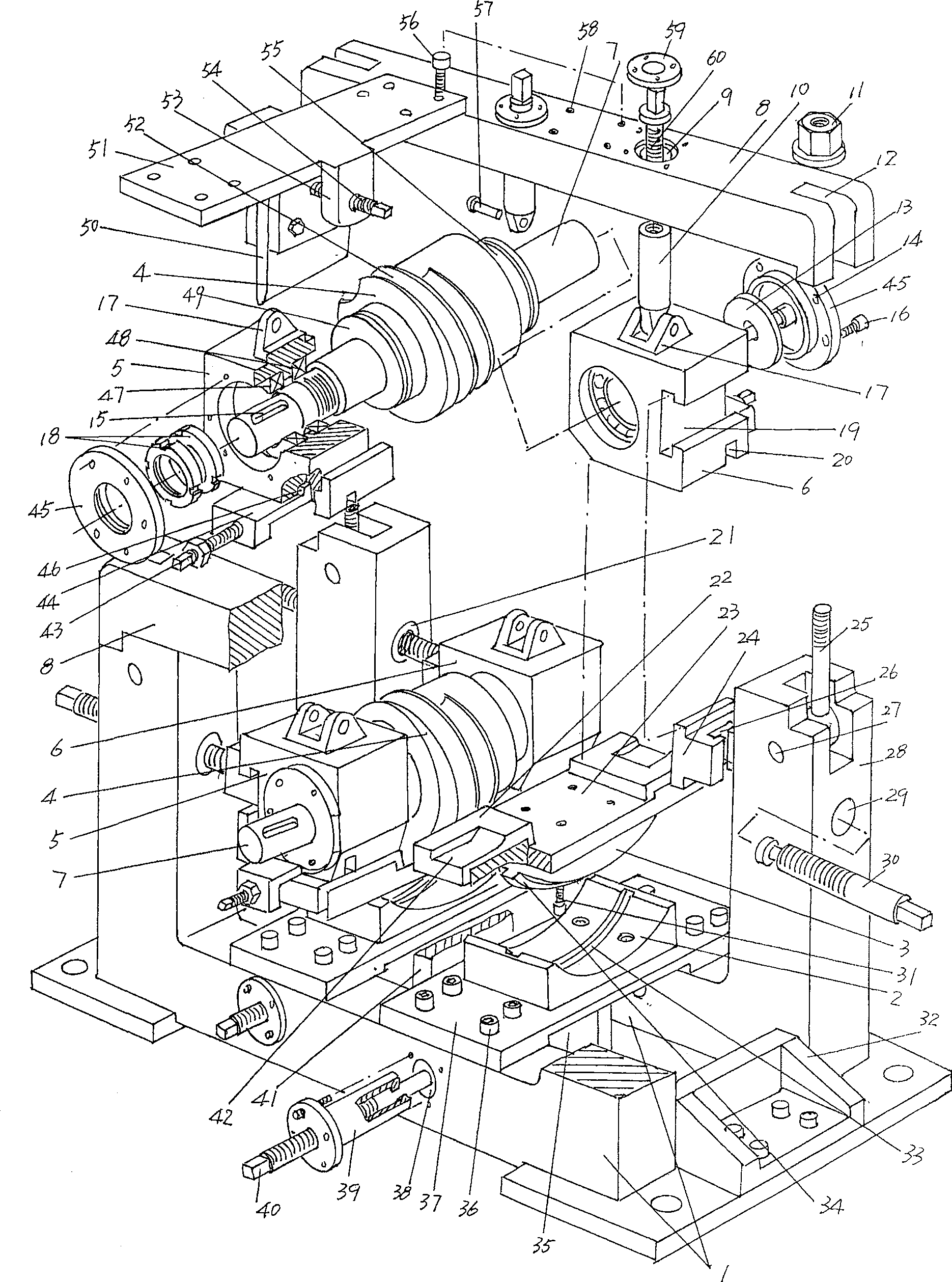

Ball forming mechanism of ball rolling machine

A ball rolling and ball forming technology, which is applied in the field of ball forming mechanism, can solve the problems of affecting the use effect of circuit boards, lengthy processing time, and influence on electrical conductivity, etc., and achieves excellent density, good overall roundness, and high ball forming efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] see figure 1 and auxiliary reference figure 2 with image 3 , provides a bracket 1, the bracket 1 is actually composed of a pair of rectangular bodies with upper openings or horseshoe-shaped structural members that are symmetrical to each other, the two are completely symmetrical, and are jointly fixed on the bracket mounting plate 32, the bracket The mounting plate 32 is used to be fixed to the ground on the site where the equipment is used. On the four bracket arms 28 of the bracket 1 and corresponding to the first and second shaft seats 5, 6, there are screw holes 29 for pressing down, and the nuts 21 for pressing down are placed in the holes, and the nuts 21 for pressing down are screwed up for pressure distribution. Lower the screw rod 30, press down the end of the screw rod 30 towards the first and second shaft seats 5, 6 and connect with the slide block 24, the specific matching method is: the end of the push down screw rod 30 is connected to the slide block 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com