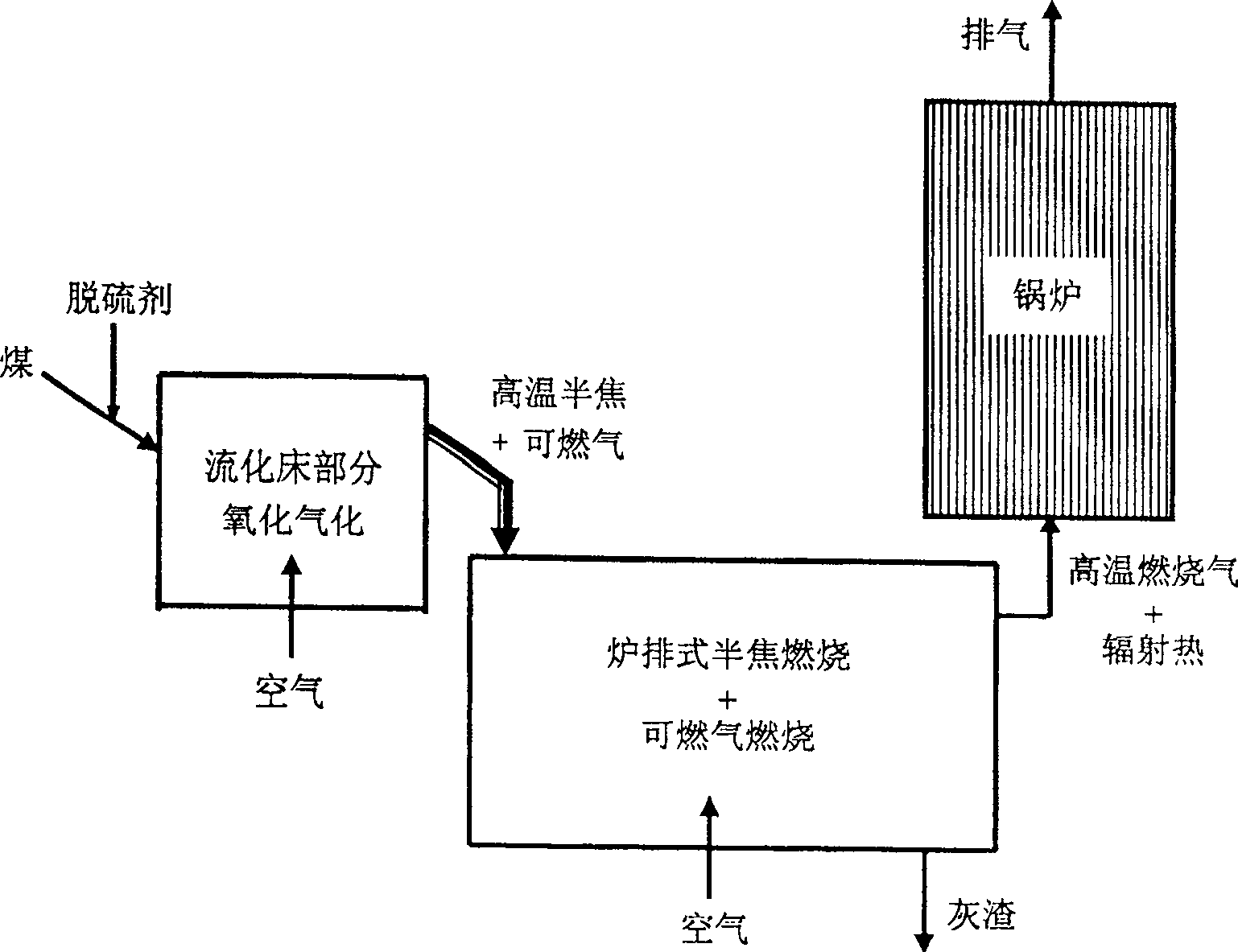

Combustion method for coal-burning boiler and combustion apparatus

A combustion method and coal-fired boiler technology, applied in the direction of combustion method, combustion of solid fuel, fuel burned in molten state, etc., can solve problems such as high smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

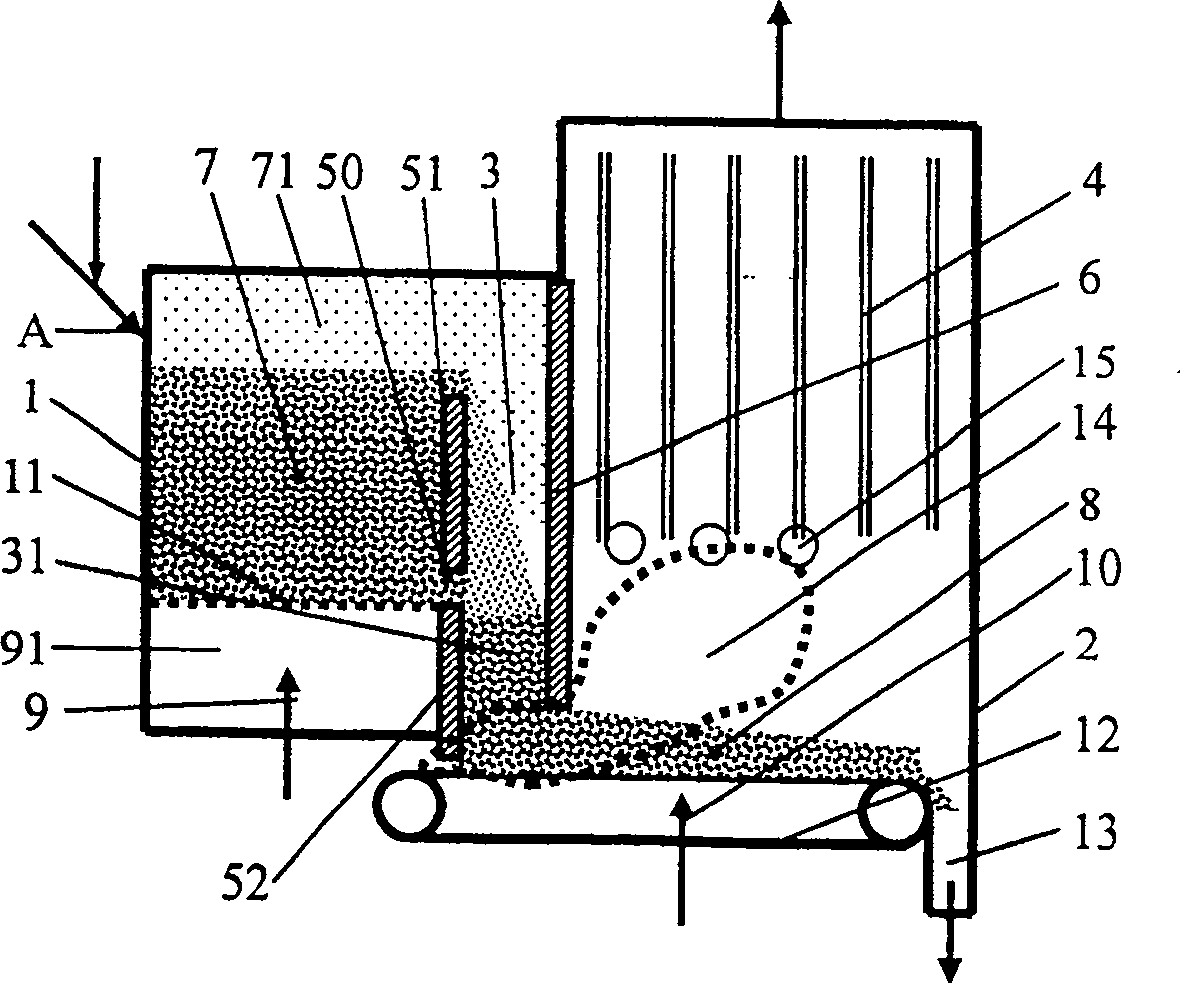

[0058] attached figure 2 For the implementation of figure 1 A schematic structural diagram of a combustion device with a chain grate combustion furnace applied to a large-capacity industrial boiler according to the combustion method of the present invention is shown. The combustion device is mainly composed of a fluidized bed gasification furnace 1, a chain grate semi-coke combustion furnace 2, a boiler heat exchanger 4 connected to the upper space of the combustion chamber 14 of the chain combustion furnace 2, and a particle flow on the left side wall. The fluidized bed rear wall 51 and the fluidized bed windbox rear wall 52 form the conveying channel 3 formed by the boiler heat exchanger front wall 6 (extended downwards) on the right side. Coal fuel and desulfurizer are supplied into the fluidized bed gasifier 1 from the other side of the conveying channel 3 . In order to facilitate the supply of fuel and desulfurizer, the supply port A is located above the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com