An electronic heating-cost distributor

An electronic heating and distributor technology, applied in calorimeters, circuit heating devices, instruments, etc., can solve the problems of prolonging the production process of printed circuit boards and damaging the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

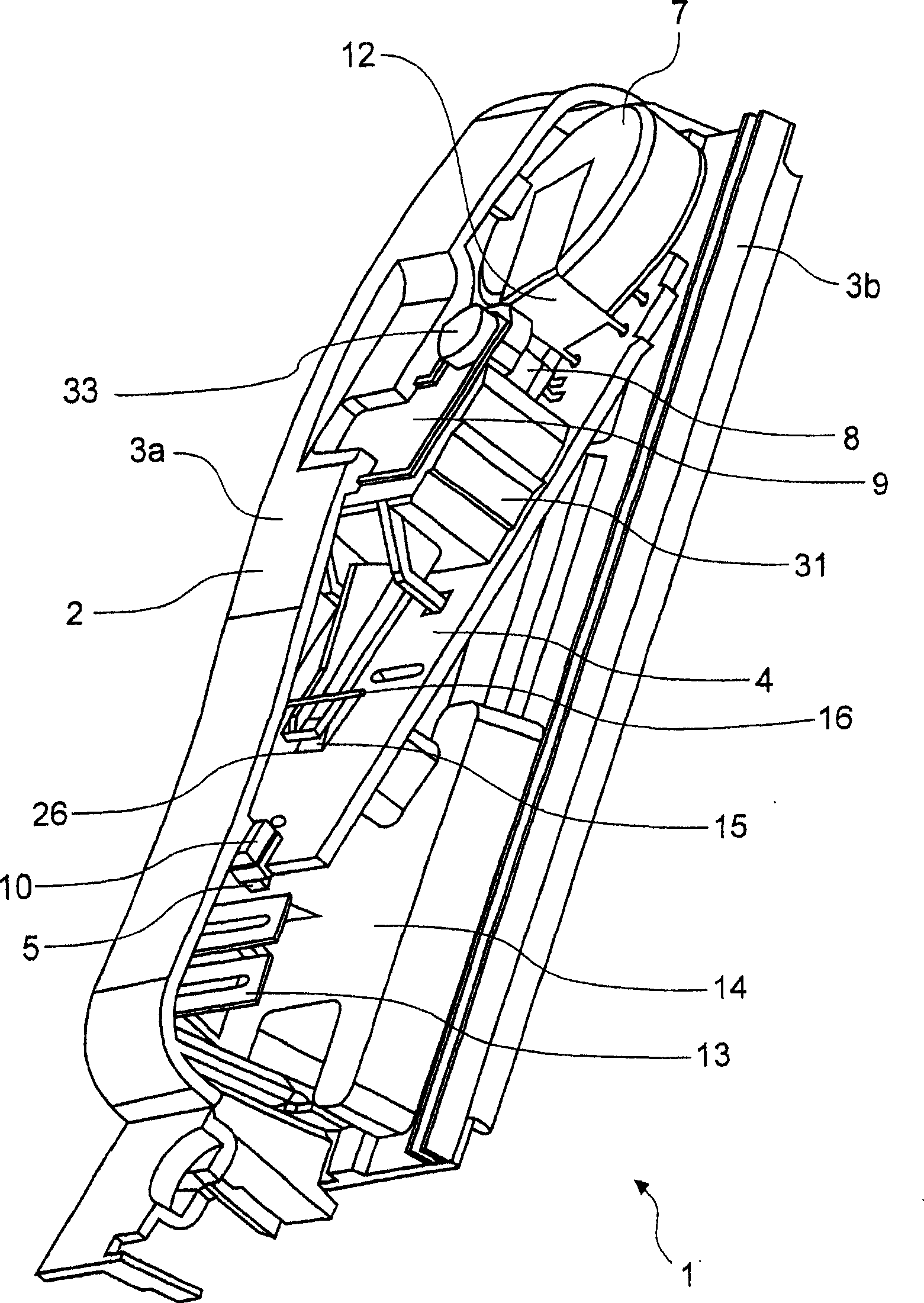

[0027] according to figure 1 The electronic heating cost allocator 1 comprises a housing 2 with a hook-shaped chamber-side housing front 3a and a rear side 3b on the heating device side for isolating the latter. Inside the housing 2, the electronic heating cost allocator 1 has a printed circuit board or circuit board 4 on which are arranged components in the form of electronics for determining the heat output by the heating device. For reading out and / or future processing of the data determined by the electronic heating cost allocator 1 , the electronic heating cost allocator 1 also includes an LC display 9 (liquid crystal display), an infrared interface 8 and a radio frequency antenna 13 .

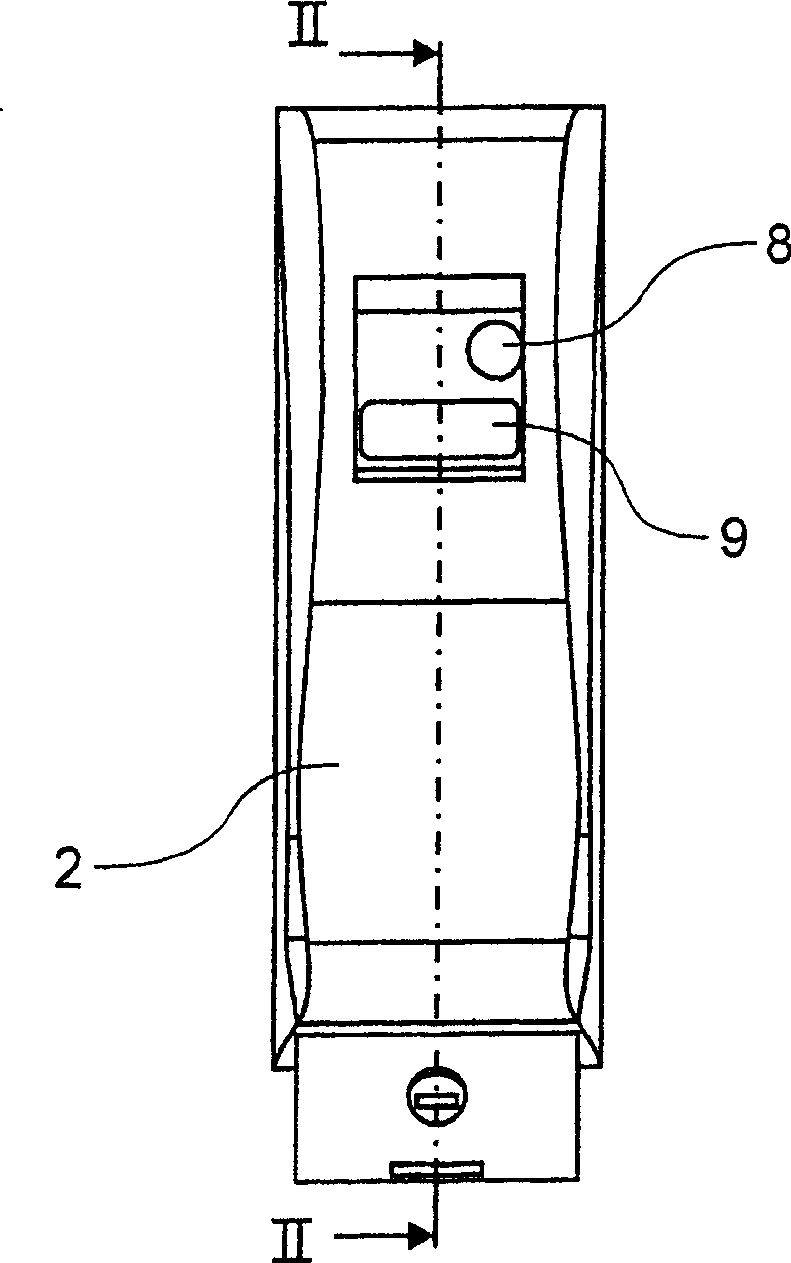

[0028] Such as image 3 As shown, the front side 3 a of the housing 2 has openings for the infrared interface 8 and the LC display 9 . The data determined by the heating cost allocator 1 can be read directly on the LC display 9 . In contrast to this, the data determined by the heating co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com