Manufacture method and die for powder metallurgy inside spin ratchet wheel

A powder metallurgy and manufacturing method technology, applied to the manufacturing method and mold field of powder metallurgy inner spiral ratchet, can solve the problems of inability to form special-shaped inner spiral gear, difficult control of rotation speed of rotating parts, damage to molds and ingredients, etc., and achieve frictional force. The effect of lowering, easier speed control, lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for manufacturing a powder metallurgy internal helical ratchet, the method comprising the following steps:

[0065] The first step, mixing ingredients: mix the following powders evenly, in terms of mass percentage, among them, copper accounts for 1.5-2%, nickel accounts for 1.7-2%, molybdenum accounts for 0.5%, carbon accounts for 0.5%, manganese sulfide accounts for 0.3%, Micro-wax powder accounts for 0.3%, and the rest is the powder of pre-alloyed iron powder, mixed evenly,

[0066] The second step, pressing and forming: put the above powder in a pressing mold with a small mandrel rotation system with a friction plate structure and press it into a green compact with an inner spiral ratchet shape, with a pressure of 1100±5KN, pressing Density ≥ 6.85g / cm 3 , such as pressing density can be 7.2g / cm 3 , 7.3g / cm 3 ,

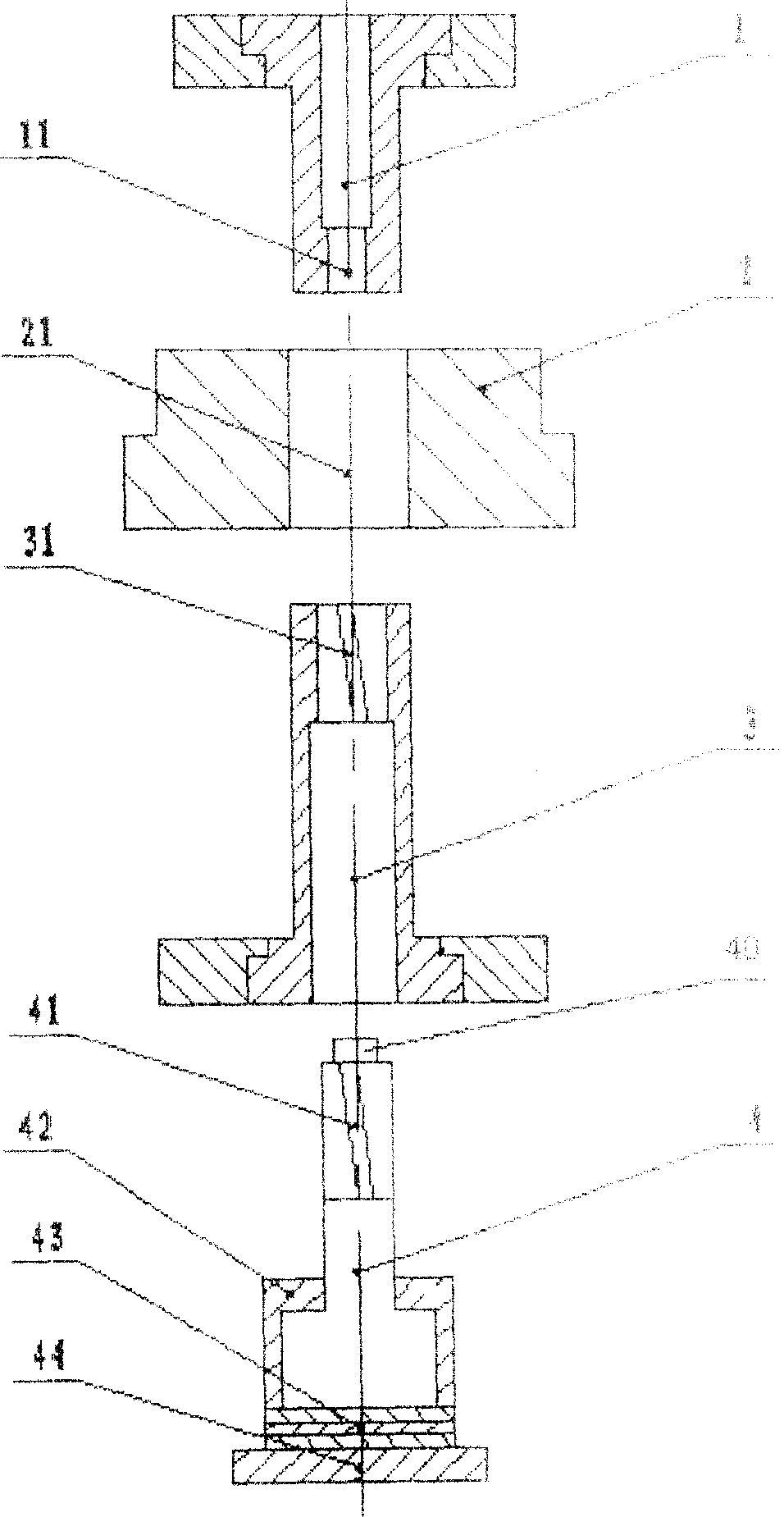

[0067] Wherein, it is composed of a pressing upper punch 1, a pressing middle die 2, a pressing lower punch 3, and a pressing mandrel member 4. ...

Embodiment 2

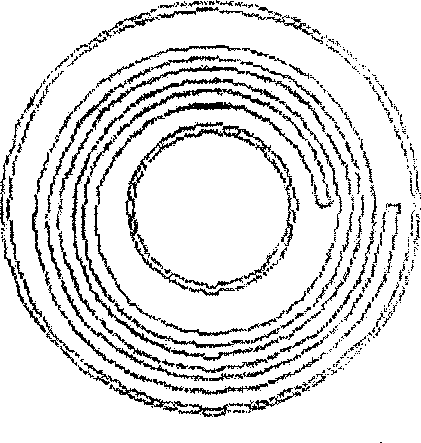

[0072] A manufacturing mold for a powder metallurgy internal spiral ratchet, which consists of a pressing upper punch 1, a pressing middle die 2, a pressing lower punch 3, and a pressing mandrel member 4. The raw material powder is placed in the pressing middle die 2 and placed in the pressing lower punch 3 and the pressing upper punch 1, the lower part of the pressing upper punch 1 is provided with a limiting hole 11 that matches the limiting block 40 at the upper end of the mandrel 4. The limiting block 40 is generally cylindrical in shape, corresponding to Cooperate, the shape of the limit hole 11 is also cylindrical, the shape of the inner mold cavity 21 of the middle die 2 is the same as the outer profile of the inner spiral ratchet, and the upper part of the lower punch 3 is provided with an outer helix that matches the pressing mandrel member 4. The inner helical tooth 31 that tooth 41 matches, and wherein the axial length of outer helical tooth 41 is longer than inner h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com