Roll type cold pressing processing method and device for vehicle driving axle housing

A technology for driving axle housing and processing method, which is applied in metal extrusion, metal processing equipment, metal extrusion control equipment, etc., can solve the problem of poor rigidity and mechanical strength of the axle housing, low material utilization rate, and poor working reliability of the axle housing. and other problems, to achieve the effect of improving the overall mechanical strength and rigidity, reducing the welding workload and enhancing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings

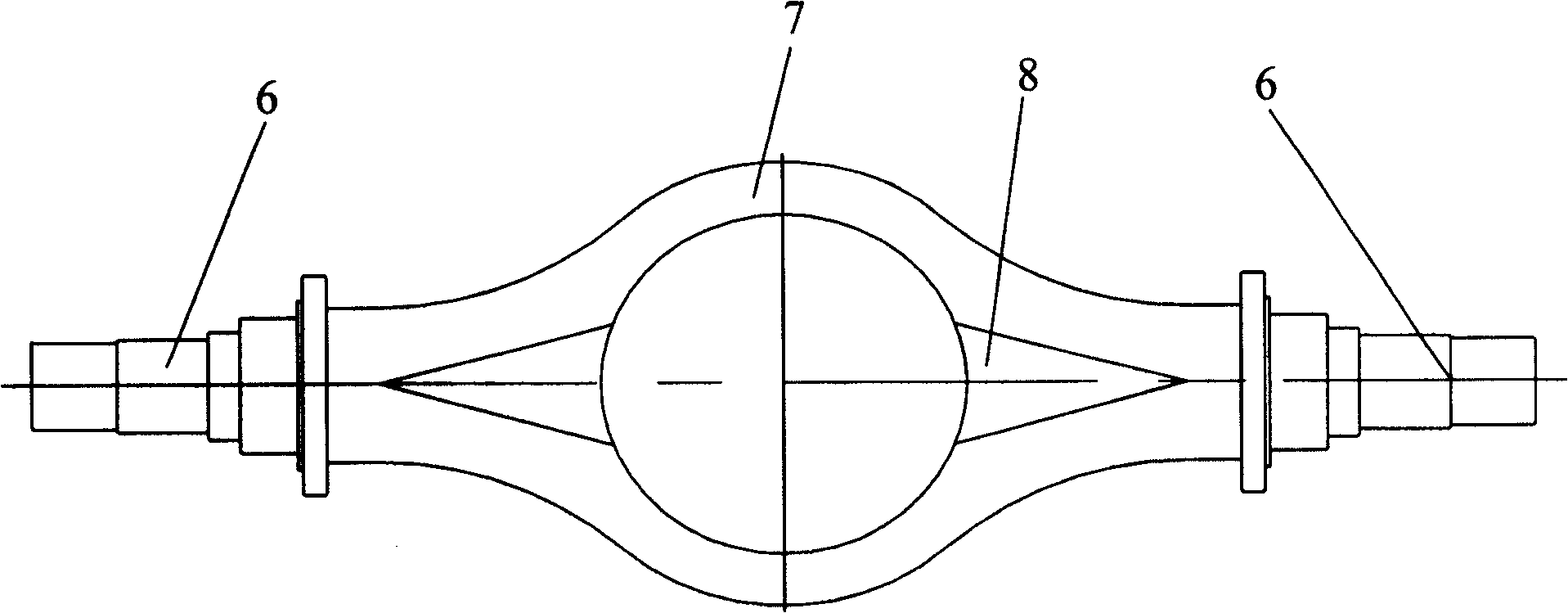

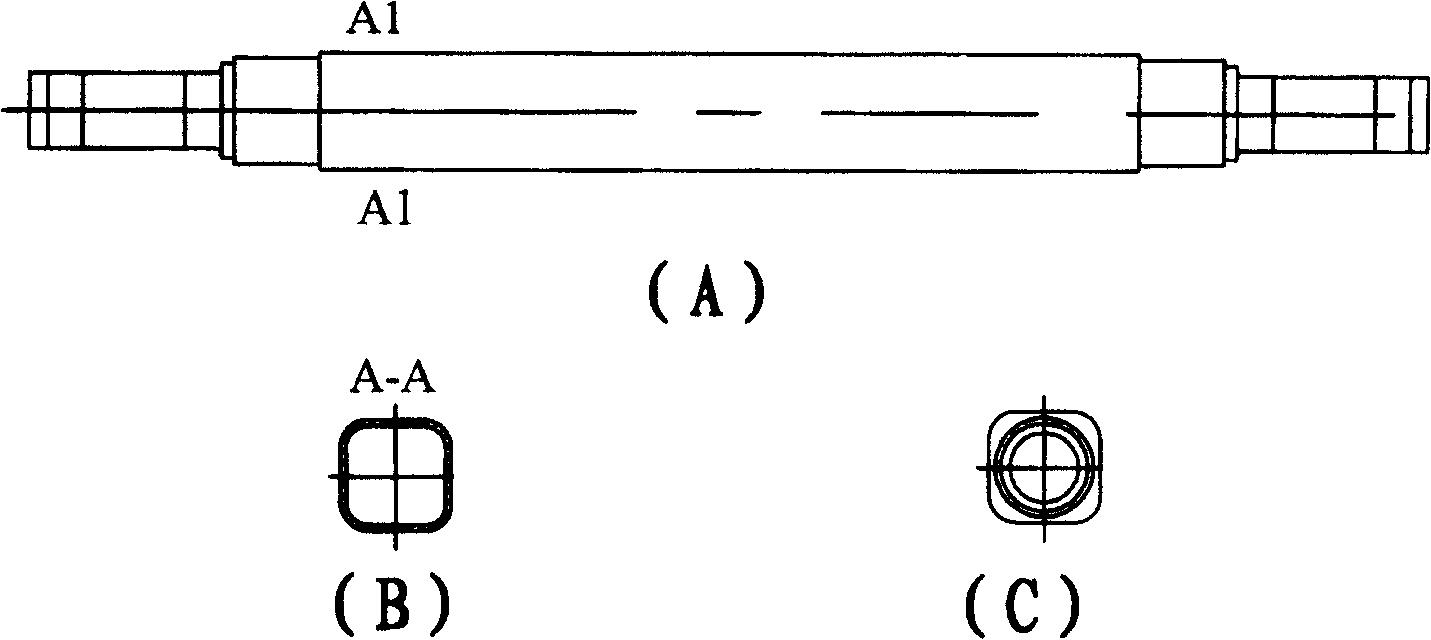

[0043] see Figure 3 ~ Figure 7 , introduce the rolling cold extrusion processing method of the automobile drive axle housing of the present invention: that is, adopt the rolling cold extrusion process to manufacture the pipa-shaped shell that expands in the middle of the drive axle housing, that is, at both ends of the axle housing blank or semi-finished axle housing Axial pressure is loaded, and in the forming die, the rolling roller in the special rolling roller driving device is used to repeatedly roll and gradually radially feed the inner wall of the workpiece to process the workpiece into the desired shape. The desired axle housing shape. The following steps of the method are briefly described below:

[0044] (1) Prepare the drive axle housing blank or sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com