Substrate integrated waveguide comb-shaped power distributor

A substrate-integrated waveguide and power divider technology, which is applied to waveguide-type devices, electrical components, connecting devices, etc., can solve the problems of high machining accuracy requirements for metal components, reduced antenna array aperture efficiency, and difficulty in mass production. The effect of easy mass production, low cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] What this embodiment describes is a substrate-integrated waveguide comb power divider involving millimeter wave and microwave devices.

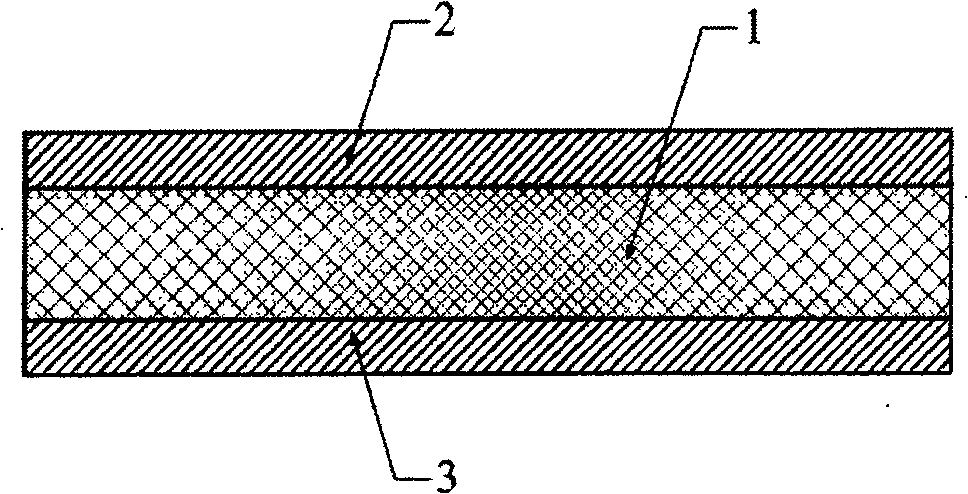

[0023] refer to figure 2 , this embodiment includes a dielectric substrate 1 covered with metal patches 2, 3 on both sides;

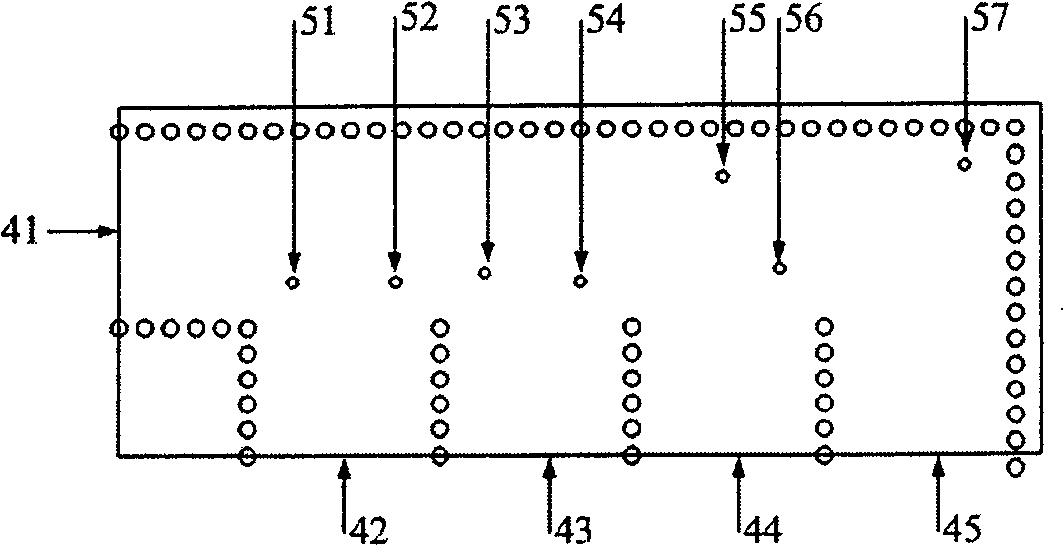

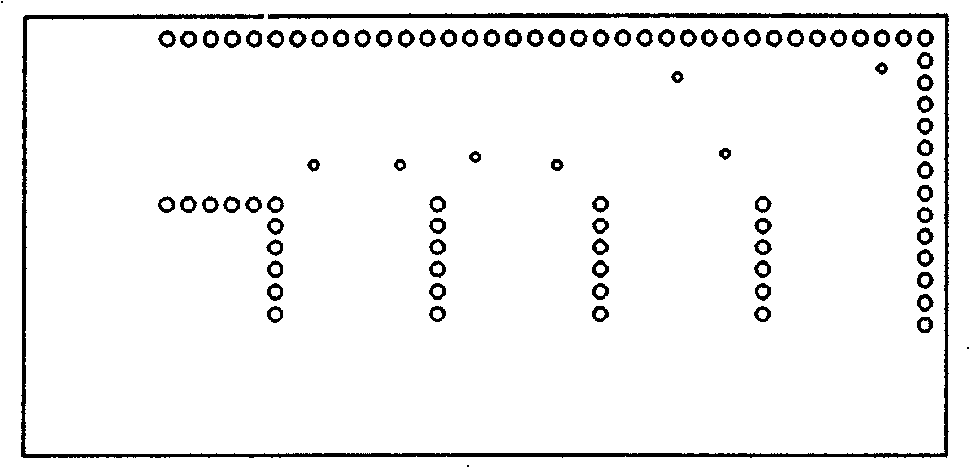

[0024] refer to figure 1 and image 3 , the dielectric substrate 1 is provided with a waveguide used as the input end 41 and a waveguide used as the output end and the output end at least includes a first output end 42 and a second output end 43, the waveguide used as the input end 41 and the waveguide used as the output end The waveguide intersects, and the above-mentioned waveguide is composed of at least 2 rows of metallized through holes. It is characterized in that the waveguide used as the input end 41 is a transverse waveguide, and the waveguide used as the output end is a longitudinal waveguide. The waveguide used as the input end 41 and the waveguide used as the second Two metallized through-holes 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com