RQVK speed governor with full-load power compensating function

A technology of power compensation and governor, applied in governor, machine/engine, engine control, etc., can solve the problems of shortened circumferential stroke of plunger pair, low actual fuel supply, low engine power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

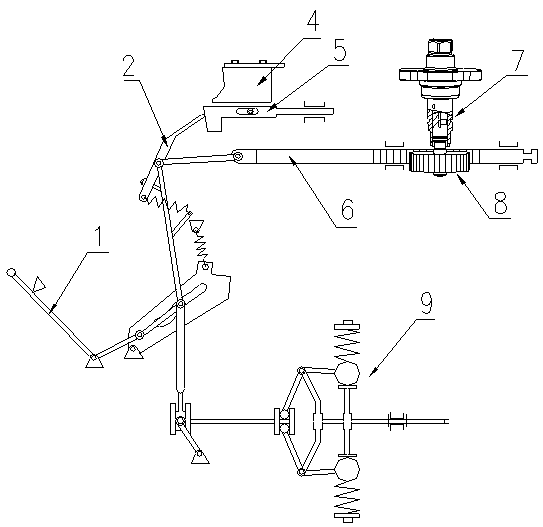

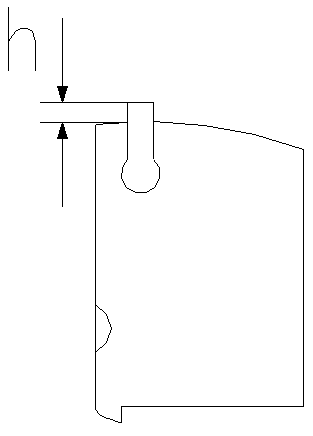

[0013] An RQVK speed governor with full load power compensation function, including a speed control handle 1, a limit piece 2 connected to the speed control handle 1, a plunger pair connected to the limit piece 2 and a counter limit piece 2 The limiter for limiting the bidirectional maximum stroke is improved in that: a compensation piece 3 is provided on the limiter 2 at a position in contact with the limiter. Due to the existence of the compensation piece 3, the limiter 2 and the The stroke of the plunger pair is relatively small (compared to the situation after the compensation plate 3 is worn); the compensation plate 3 is made of low wear-resistant material, and the limit plate 2 and the limiter are both made of high wear resistance made of materials;

[0014] After the new equipment is put into operation, the compensating sheet 3 and the plunger pair wear synchronously. With the gradual wear of the compensating sheet 3, the strokes of the limiting sheet 2 and the plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com