Automatic indexer for cam shaft grinder

An automatic indexing and camshaft technology, which is applied in the direction of grinding machines, abrasive belt grinding machines, grinding/polishing equipment, etc., can solve problems such as difficult to ensure consistent contour accuracy, difficult cam template technology, and poor profile consistency. Achieve the effects of reducing technical difficulty and labor intensity, reducing manufacturing difficulty, and good mold line consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

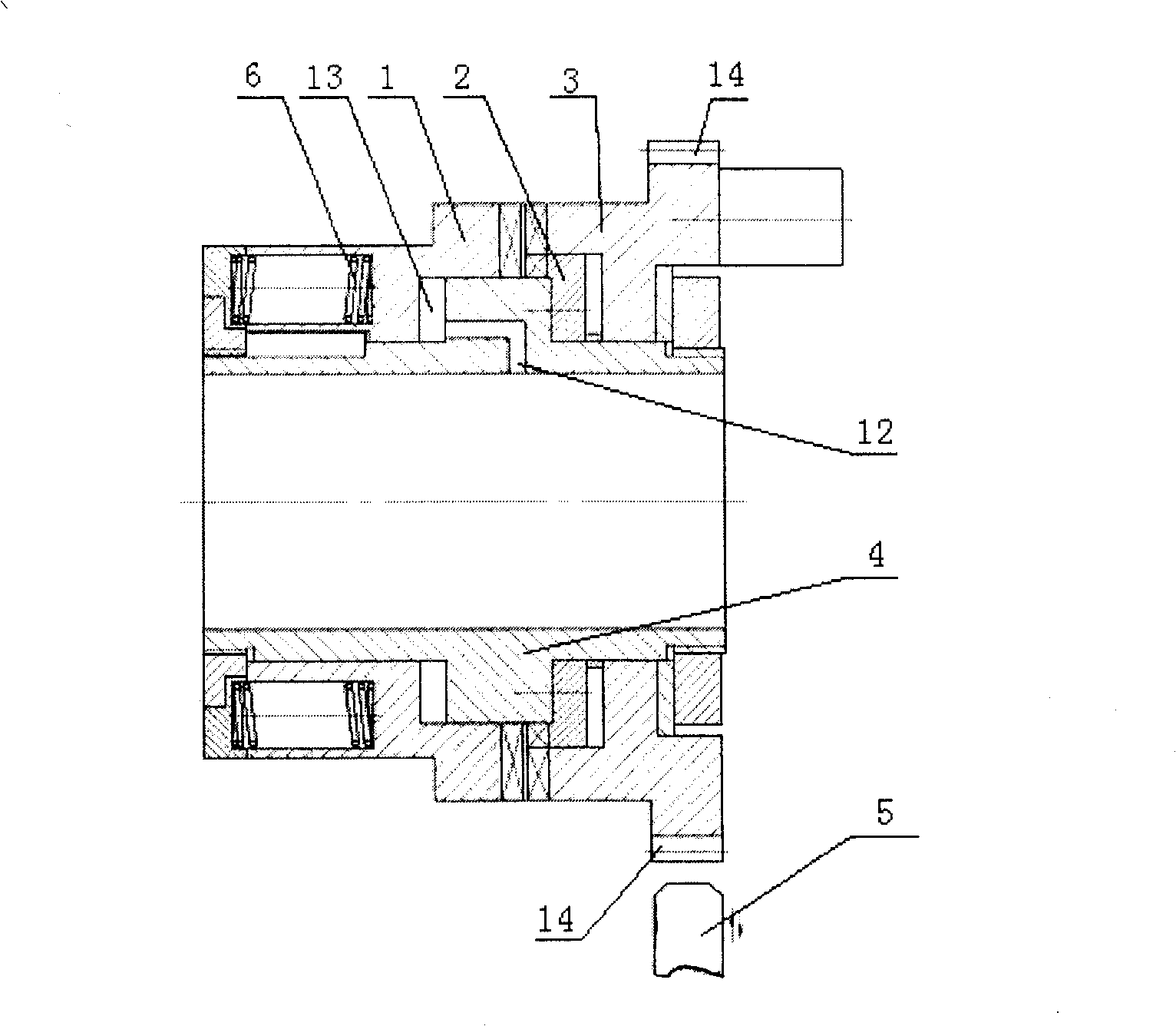

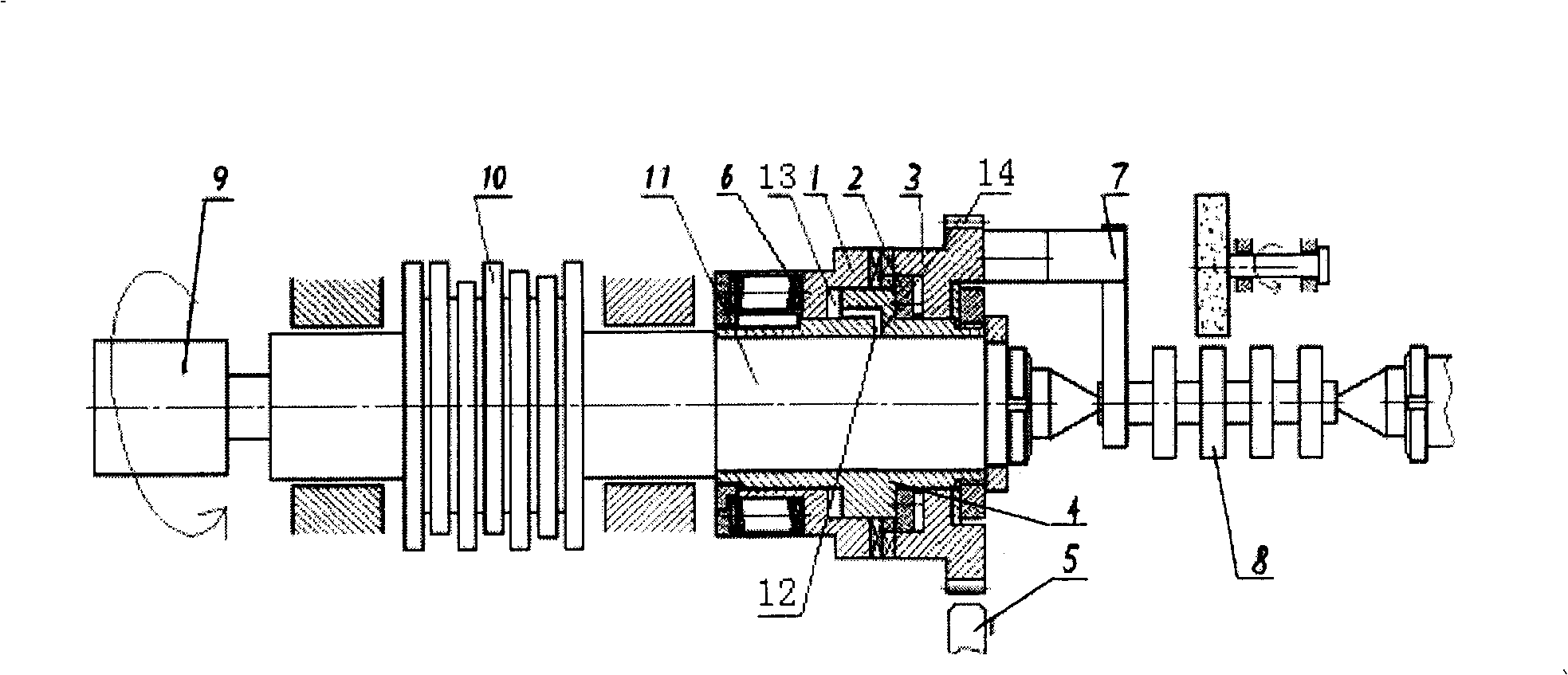

[0021] Such as figure 1 , 2 The shown device of the present invention is applied to MKS8312 numerically controlled high-speed camshaft grinding machine. The clutch mechanism adopts three face gears and the number of teeth of the first face gear 3, the second face gear 1 and the third face gear 2 is 48 teeth (it can also be determined according to The diameter of the face gear makes the number of teeth 96), and the minimum graduation is 7.5 degrees, which is the largest common divisor of the phase angles between all cams on the camshaft, which can meet the graduation requirements of the cam phase angles of all camshafts in production; The structure of the driving mechanism for the axial sliding of the two end gears 1 is that an oil chamber 13 is set between one end face of the second end face gear 1 and the hollow shaft 4 and communicates with the oil passage 12. There is a return spring 6 between the other side of the gear 1 and the axial direction of the hollow shaft 4; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com