Headlight for vehicle with adjustable mirror

A technology of reflectors and headlights, which is applied in the direction of headlights, lighting devices, vehicle parts, etc., can solve the problems of increased manufacturing costs and complicated metal mold structures, and achieve the effect of avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] Embodiments of the present invention will be described below based on examples.

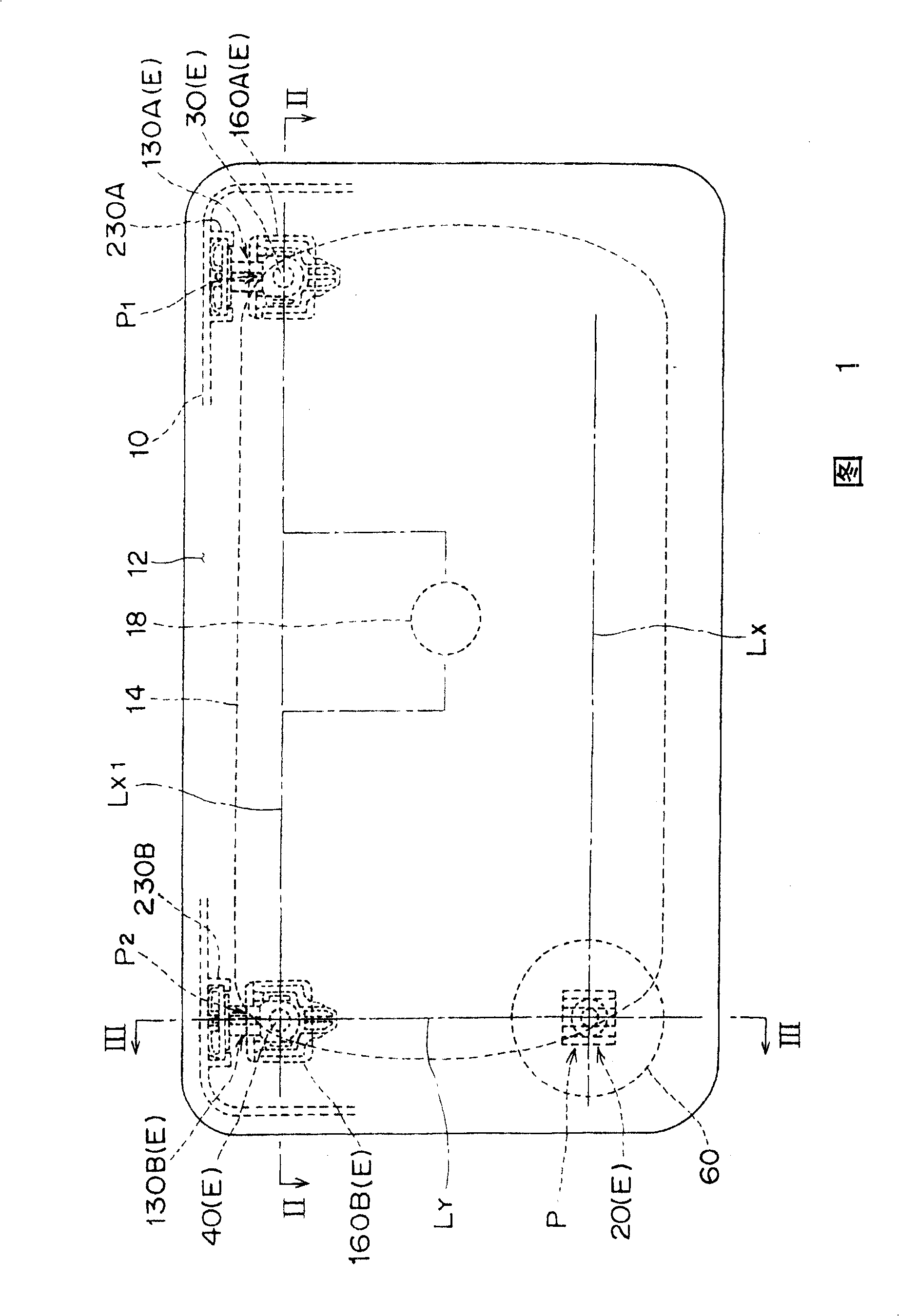

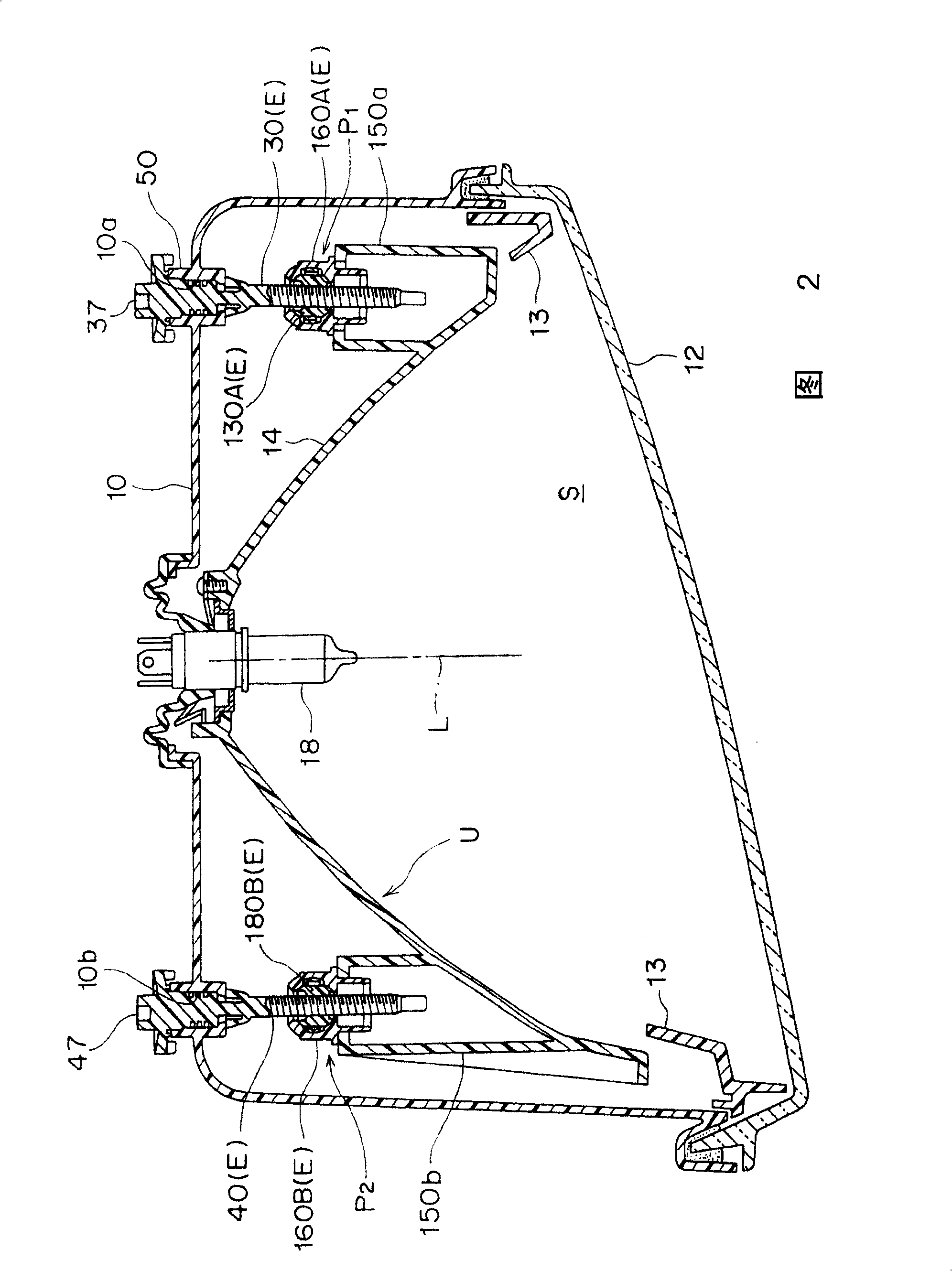

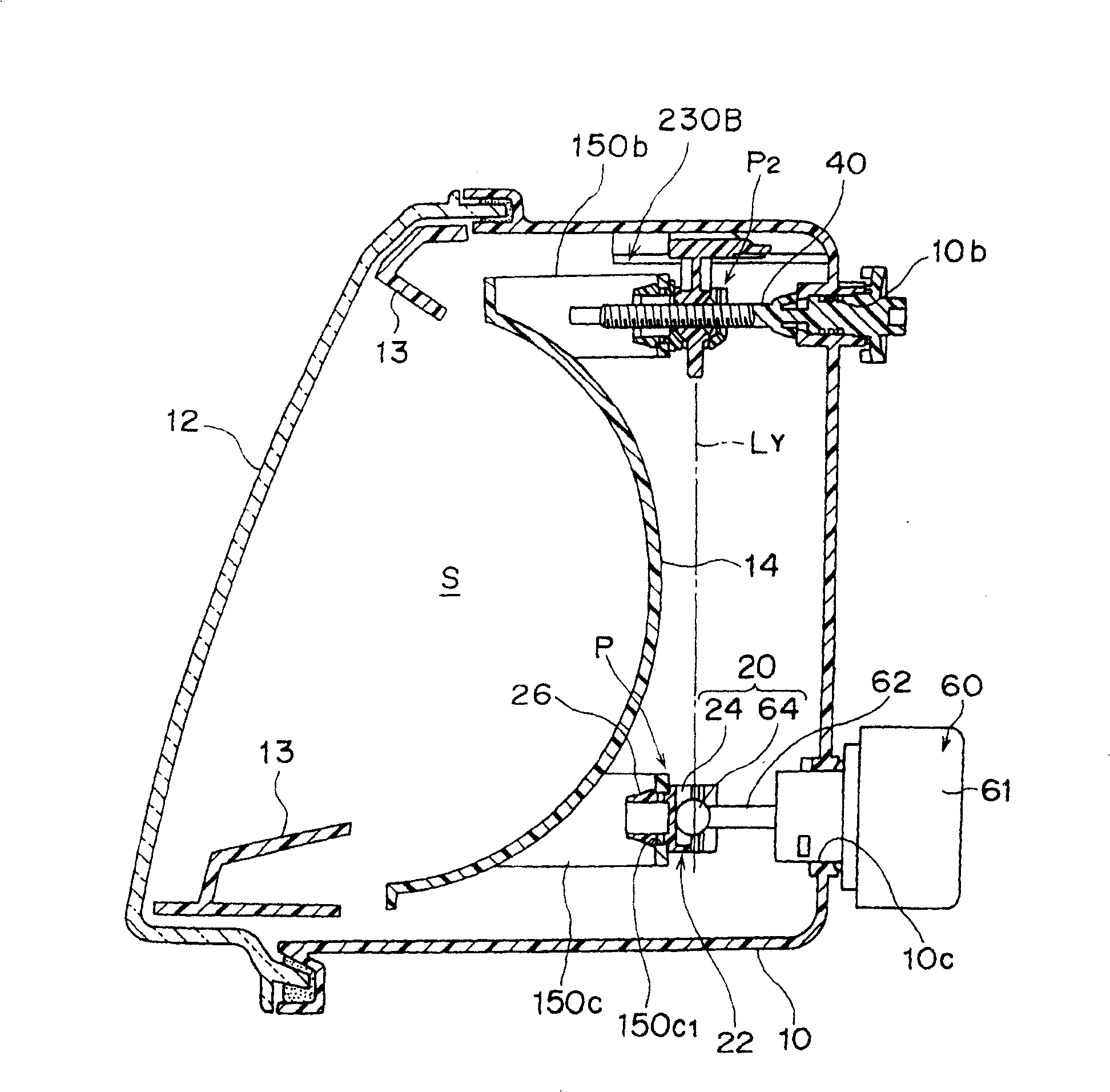

[0104] Figure 1~ Figure 16 Show the 1st embodiment of the present invention, Fig. 1 is the front view of the reflector movable type automobile headlamp of the 1st embodiment of the present invention, Fig. 2 is the horizontal sectional view of this headlamp (along Fig. The profile of the II-II line), image 3 It is a longitudinal sectional view of the headlamp (the sectional view along the III-III line shown in Fig. 1), and Fig. 4 is an exploded perspective view of the lamp body, reflector and dimming mechanism, Figure 5 It shows the cylindrical part which comprises the rotation support part of a dimming screw, (a) is an enlarged perspective view of this cylindrical part, (b) is an enlarged vertical cross-sectional view of this cylindrical part. Figure 6 Indicates the dimming screw, (a) is the enlarged perspective view of the dimming screw, (b) is the enlarged side view of the dimming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com