Battery and method of producing the same

A manufacturing method and battery technology, which can be applied to battery pack parts, final product manufacturing, battery case/housing, etc., which can solve the problems of gasket wall thickness becoming thinner and insufficient sealing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

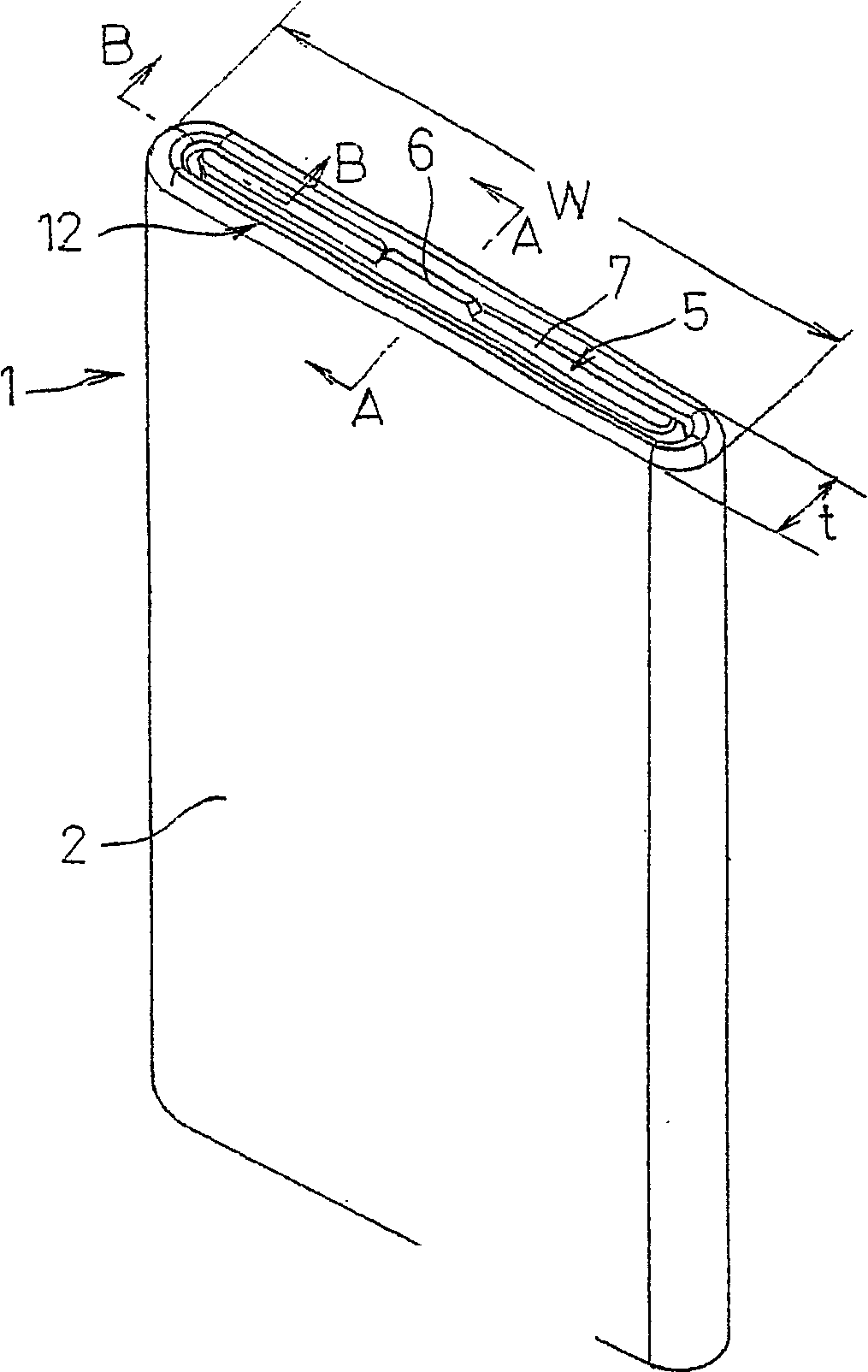

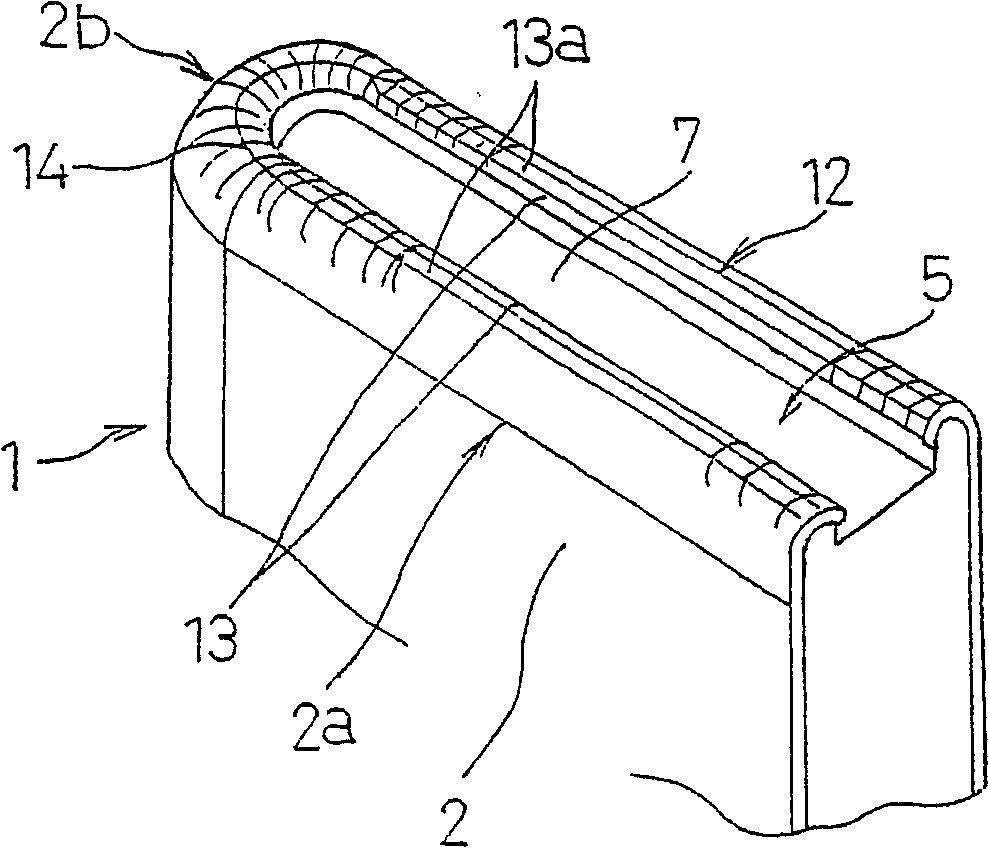

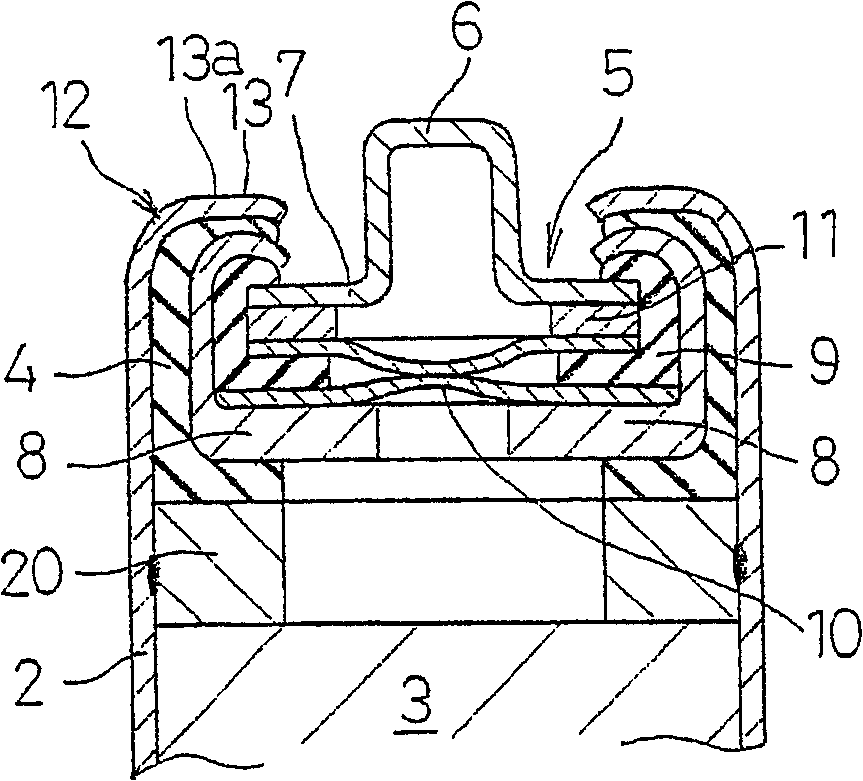

[0020] Refer below Figure 1A ~ FIG. 4C uses lithium-ion rechargeable batteries to illustrate the battery and its manufacturing method in one embodiment of the present invention, but as long as the cross-sectional shape is oblong and flat, the present invention is not particularly limited, and is also applicable to nickel-cadmium batteries or batteries such as NiMH batteries.

[0021] exist Figure 1A ~ Figure 1B Among them, 1 is a battery composed of a lithium-ion rechargeable battery, which is a flat shape with a cross-sectional shape of an elongated oval, a thickness dimension of t, and a width dimension W of about 4t to 8t. battery 1 as figure 2 , image 3 As shown, it is composed of a battery case 2 with a bottomed flat battery case 2 with an open upper end, in which an electrode plate group in which a positive electrode plate and a negative electrode plate are opposed to each other and a power generating element 3 composed of an electrolyte solution are housed. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com