Improved process for forming plastic clothes rack

A hanger and plastic technology, which is applied in the molding field of making plastic hangers, can solve the problems of insufficient filling of the distal cavity, affecting the appearance of the hanger, and large injection pressure loss, etc., to achieve shortened cooling molding time, beautiful appearance, and easy injection short distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

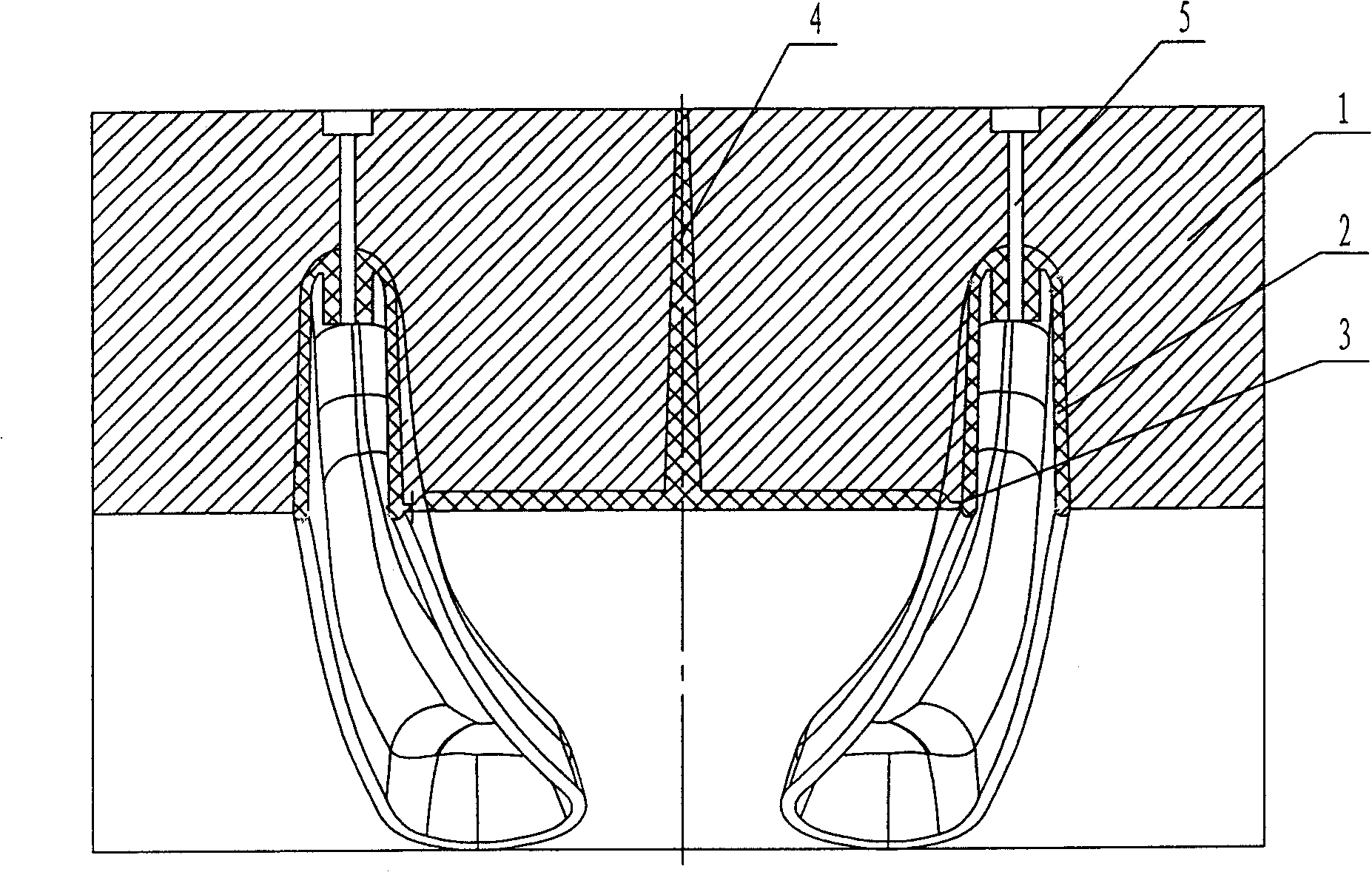

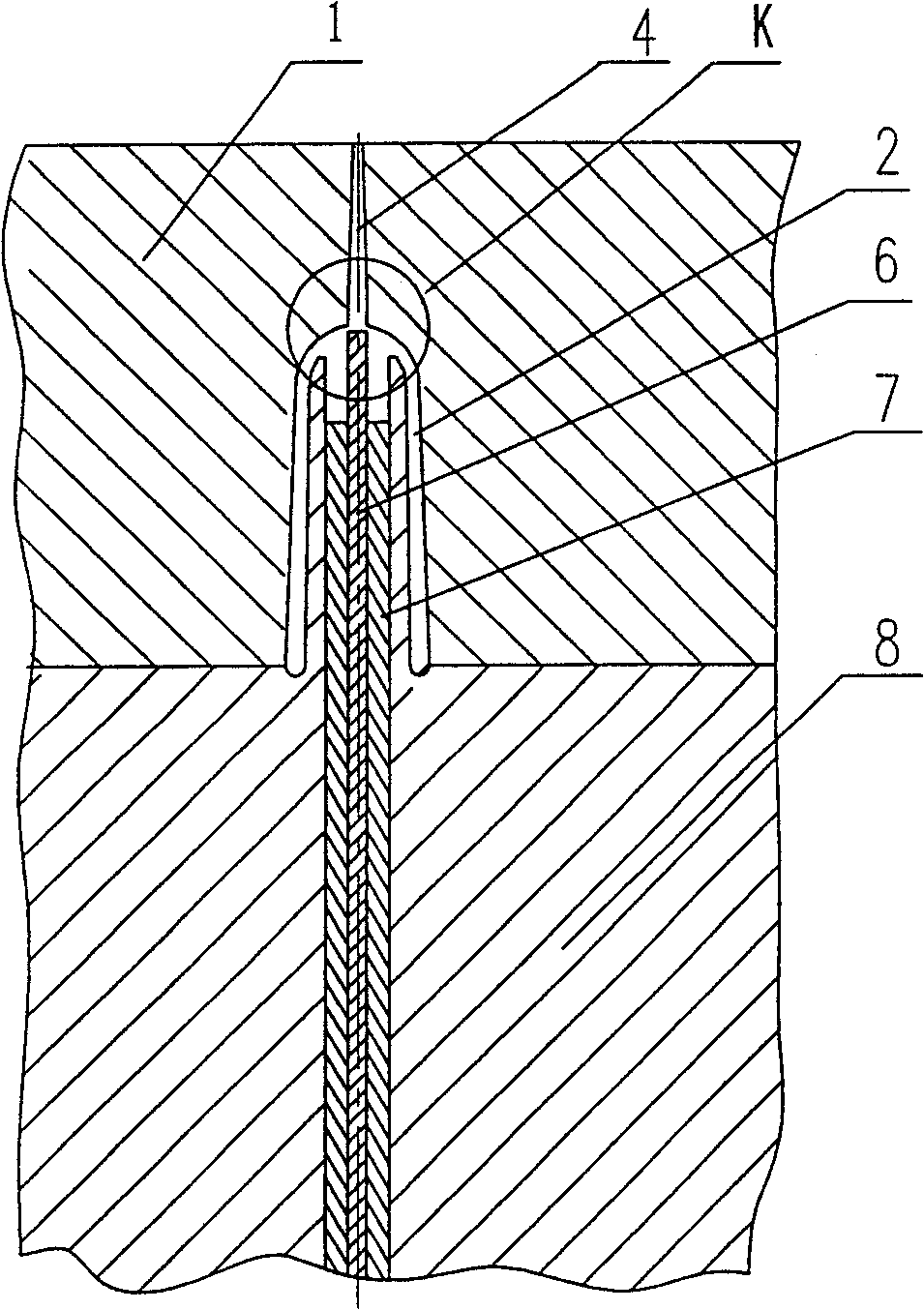

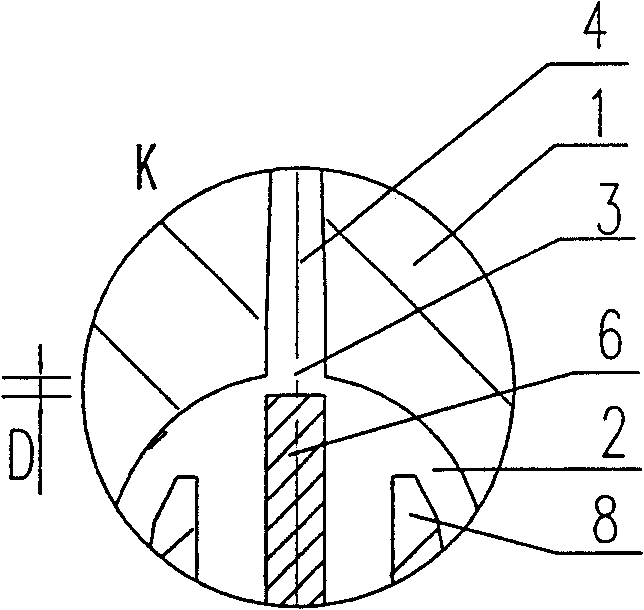

[0011] refer to figure 2 , image 3 , the hanger plastic mold of the present invention mainly contains cavity mold 1 and core mold 8, and the gap between the two forms the clothes hanger cavity 2 after fastening, and the gate 3 is located at the mold of the hanger hook hole corresponding to the cavity 2. The position of the cavity mold, the top of the cavity mold 1 and the gate 3 are connected by the gate runner 4, and the gate runner 4 replaces the core-pulling channel used to form the hanger hole in the prior art. The injection molding process is the same as the existing technology for making clothes hangers, the difference is that after the mold is closed, the molten plastic is injected from the top of the cavity mold 1, through the gate runner 4, and then injected from the gate 3 on the top of the hanger cavity 2 In the hanger cavity 2, open the mold after curing according to the routine. Since the injection starts from the top of the inverted U-shaped section of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com