Manganese ion lithium silicate/carbon composite anode material for rechargeable lithium battery and method for preparing the same

A technology of lithium manganese iron silicate and positive electrode materials, which is applied in the direction of battery electrodes, silicon compounds, chemical instruments and methods, etc., can solve the problems of poor conductivity, achieve the effects of preventing sintering and agglomeration, good rate performance, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

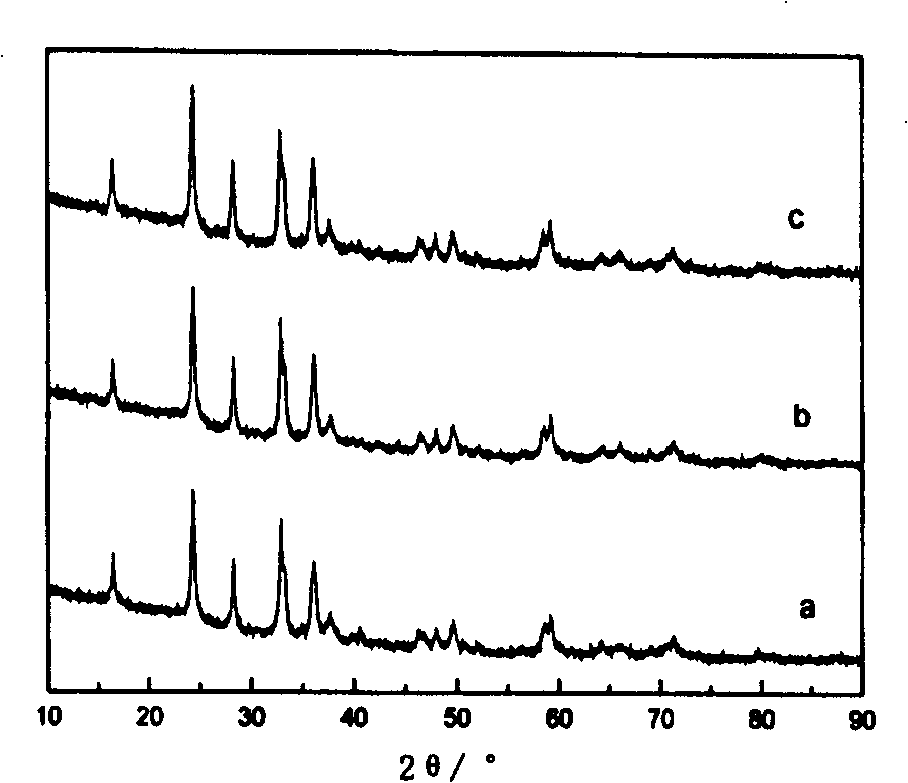

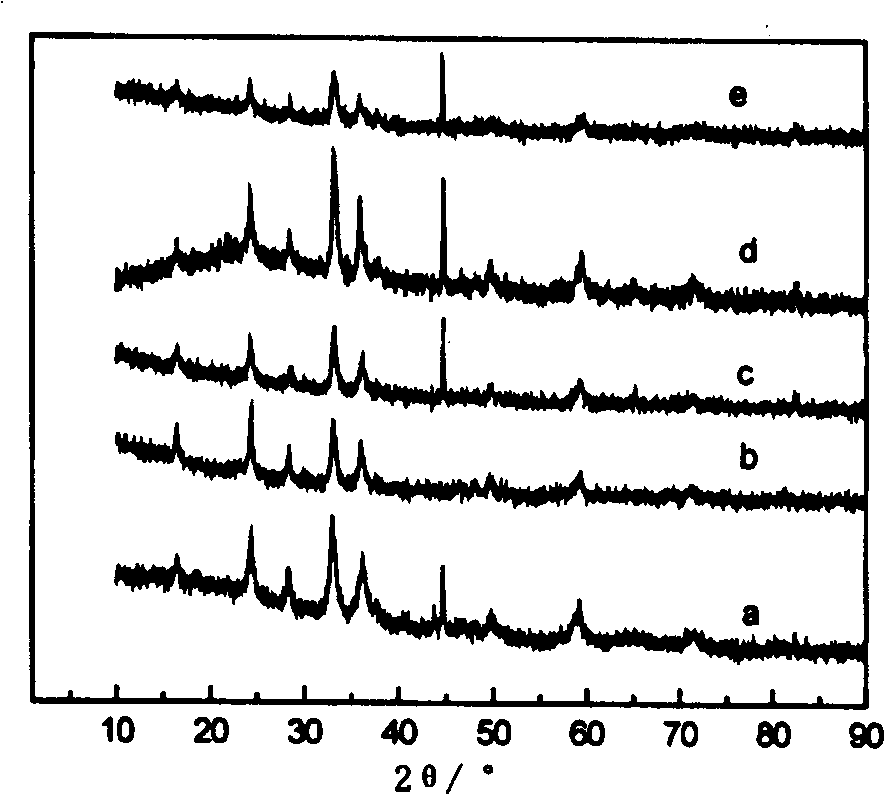

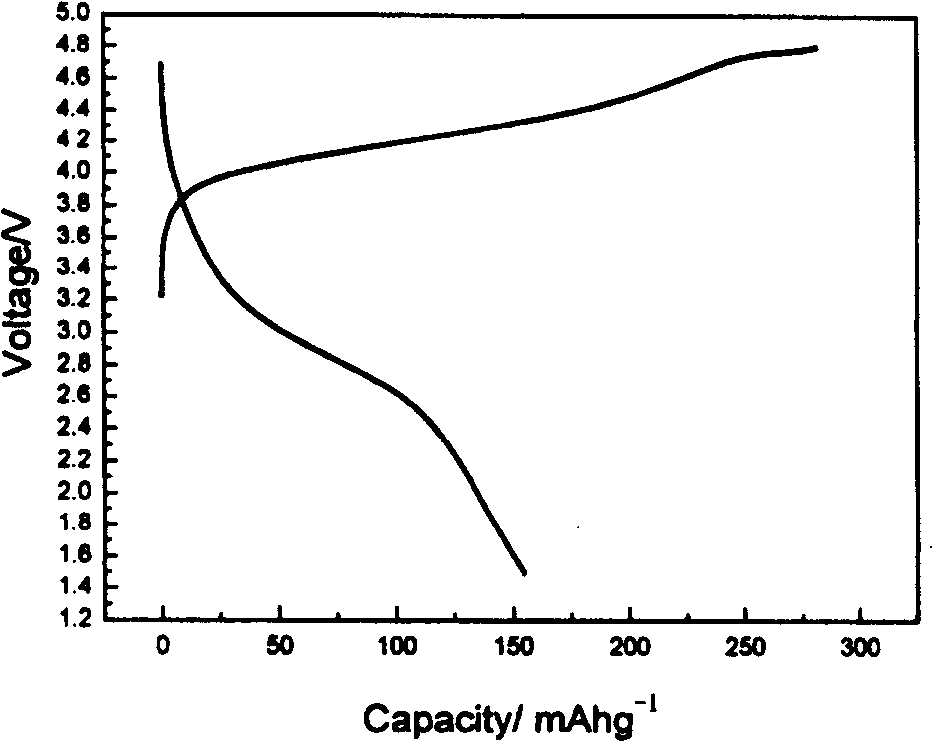

Embodiment 1

[0026] 10.2g LiAc·2H 2 O, 12.25g Mn(Ac) 2 4H 2 O and 10.42g Si(OC 2 h 5 ) 4 Add it to 100ml of ethanol, react in an oil bath at 80°C for 12h, transfer to an evaporating dish and dry at 120°C. Then the mixture obtained was transferred to an agate ball mill jar, 2g of sucrose was added, and 30ml of acetone was used as a dispersant, and ball milled for 5h (rotation speed 500r / min). After the acetone is volatilized, it is transferred to a porcelain boat and placed in a tube resistance furnace under N 2 Under protection, heat treatment at 650° C. for 10 h, and naturally cool to room temperature to obtain the composite material. In the total mass of this complex, Li 2 MnSiO 4 95% and C 5%. Composite material according to mass ratio: acetylene black: binder = 80:10:10, ball milled and mixed, coated on the treated aluminum foil, dried at 120°C, pressed and molded at 20MPa to obtain a positive electrode for a rechargeable lithium battery .

Embodiment 2

[0028] 5.1g LiAc·2H 2 O, 6.12g Mn(Ac) 2 4H 2 O and 5.21g Si(OC 2 h 5 ) 4 Add it to 60ml of ethanol, react in an oil bath at 60°C for 30h, transfer it to an evaporating dish and dry it at 100°C. Then the resulting mixture was transferred to an agate ball mill jar, 2.5 g of sucrose was added, and 20 ml of acetone was used as a dispersant for ball milling for 4 h (rotation speed 550 r / min). After the acetone is volatilized, it is transferred to a porcelain boat and placed in a tube resistance furnace under N 2 Under protection, heat treatment at 600° C. for 15 hours, and naturally cool to room temperature to obtain the composite material. In the total mass of this complex, Li 2 MnSiO 4 91% and C 9%. Composite material according to mass ratio: acetylene black: binder=80:10:10, ball milling and mixing, coating on the treated aluminum foil, drying at 120°C, pressing and molding at 20MPa to obtain the positive electrode for rechargeable lithium battery .

Embodiment 3

[0030] 10.2g LiAc·2H 2 O, 12.25g Mn(Ac) 2 4H 2 O and 10.42g Si(OC 2 h 5 ) 4 Add it to 150ml of ethanol, react for 12h in an oil bath at 80°C, transfer to an evaporating dish and dry at 120°C. The resulting mixture was then transferred to an agate ball mill jar, 8.6 g of sucrose was added, and 30 ml of acetone was used as a dispersant for ball milling for 5 h (rotation speed 500 r / min). After the acetone is volatilized, it is transferred to a porcelain boat and placed in a tube resistance furnace under N 2 Under protection, heat treatment at 550° C. for 20 h, and naturally cool to room temperature to obtain the composite material. In the total mass of this complex, Li 2 MnSi0 4 84% and C 16%. Composite material according to mass ratio: acetylene black: binder=80:10:10, ball milling and mixing, coating on the treated aluminum foil, drying at 120°C, pressing and molding at 20MPa to obtain the positive electrode for rechargeable lithium battery .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com