Method and apparatus for electrolytic synthesis of 3,6-dichloropyridine-carboxylic acid

A diclopyridine, electrolytic synthesis technology, applied in 3 fields, can solve the problems of endangering the health of workers and residents around the factory, large amount of dichloromethane, and increased operation steps, etc., to achieve great practical value and social and economic benefits, operation Stable process and good mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

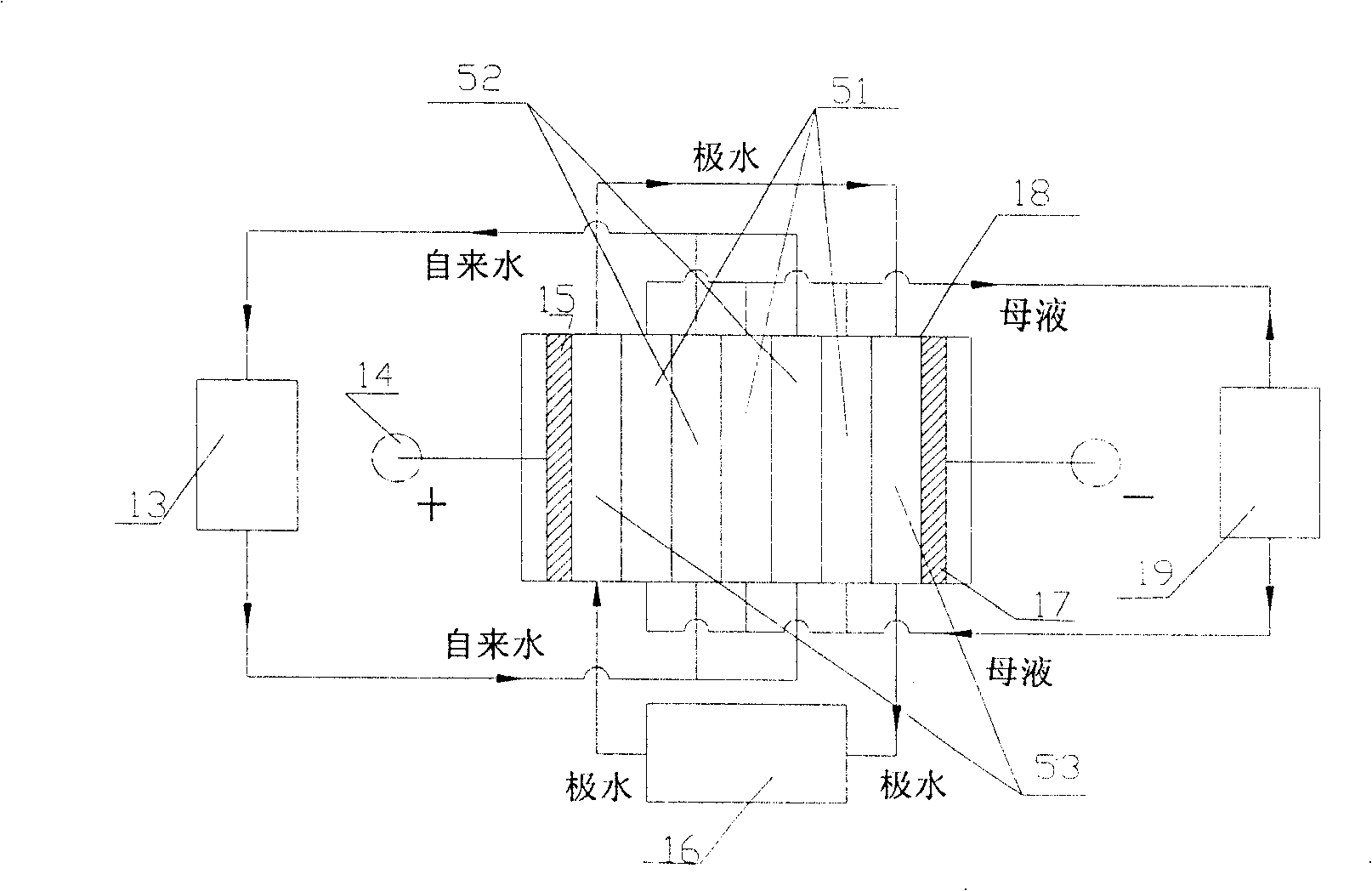

[0065] refer to figure 1 , 6 , 7, 8, a kind of 3, the electrolytic synthesis equipment of 6-dichloropicolinic acid, comprise power supply 1, batching tank 12, electrolyzer 5, described power supply 1 is the periodic reversing power supply of voltage-stabilizing silicon controlled rectifier, The power supply 1 is connected to a current commutator 2, and the current commutator 2 is provided with a program control unit; the positive pole of the power supply 1 is connected to the anode of the electrolyzer, and the negative pole of the power supply 1 is connected to the cathode of the electrolyzer.

[0066] The anode is composed of a tab 40 , a rhombus mesh plate 41 and a current collector 42 . The cathode is supported by a polypropylene substrate 54 . The anode plate has a longitudinal diamond-shaped network structure, and the cathode plate has a transverse diamond-shaped network structure. The diamond-shaped network structure is formed by connecting a plurality of identical par...

Embodiment 2

[0070] refer to figure 1 , 6 , 7, 8, the only difference between this embodiment and embodiment 1 is the size of the electrolytic cell. The electrolytic cell of the present embodiment adopts the box-type electrolytic cell with a volume of 1200ML. In the electrolytic cell, a vertical rhombic mesh Hastelloy C-276 nickel alloy anode and a zigzag rhombic silver mesh cathode are placed in parallel. The distance between the electrodes is 2cm. Total working area 100cm 2 , the total area of cathode macro work is 100cm 2 , anode size: macro length, width and thickness are 10.0cm×10.0cm×0.3cm, Ts is 1mm, LWD is 5mm, SWD is 2mm, Ws is 3mm; cathode size: macroscopic length, width and thickness are 10.0cm×10.0 cm×0.2cm, Ts is 0.5mm, LWD is 2mm, SWD is 1mm, Ws is 1.5mm.

[0071] Add 50g of 3,4,5,6-tetrachloropicolinic acid, 50g of sodium hydroxide and 1000ML of deionized water into the electrolytic cell. After dissolving, turn on the magnetic pump (the flow rate is 5.5-6.5L / min) to ci...

Embodiment 3

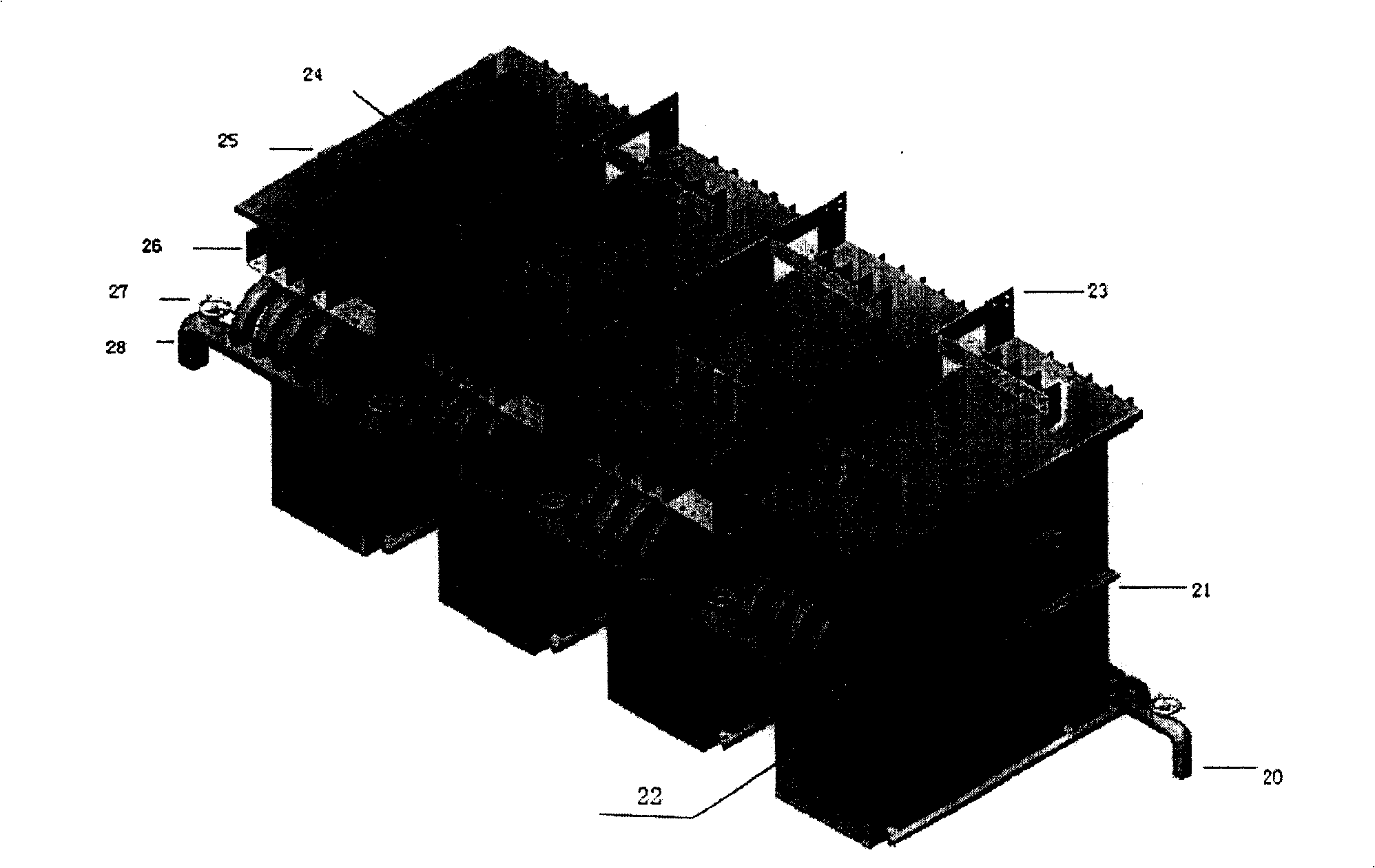

[0073] refer to figure 1 , 3 , 4, 6, 7, 8, a kind of electrolytic synthesis equipment of 3,6-dichloropicolinic acid, comprising a power supply 1, a batching tank 12, and an electrolytic tank 5, and the power supply is a voltage-stabilizing and current-stabilizing thyristor periodically changing To the power supply, the power supply 1 is connected to the current commutator 2, and the current commutator is provided with a program control unit; the positive pole of the power supply 1 is connected to the anode of the electrolyzer, and the negative pole of the power supply 1 is connected to the cathode of the electrolyzer.

[0074] The electrolyzer of this embodiment adopts image 3 A single-stage electrolyser in a battery of box-type electrolysers without diaphragms shown. The interior of the unipolar electrolytic cell is provided with 2 pieces of longitudinal diamond-shaped mesh Hastelloy C-276 nickel alloy as anodes and 1 piece of horizontal diamond-shaped silver mesh as catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com