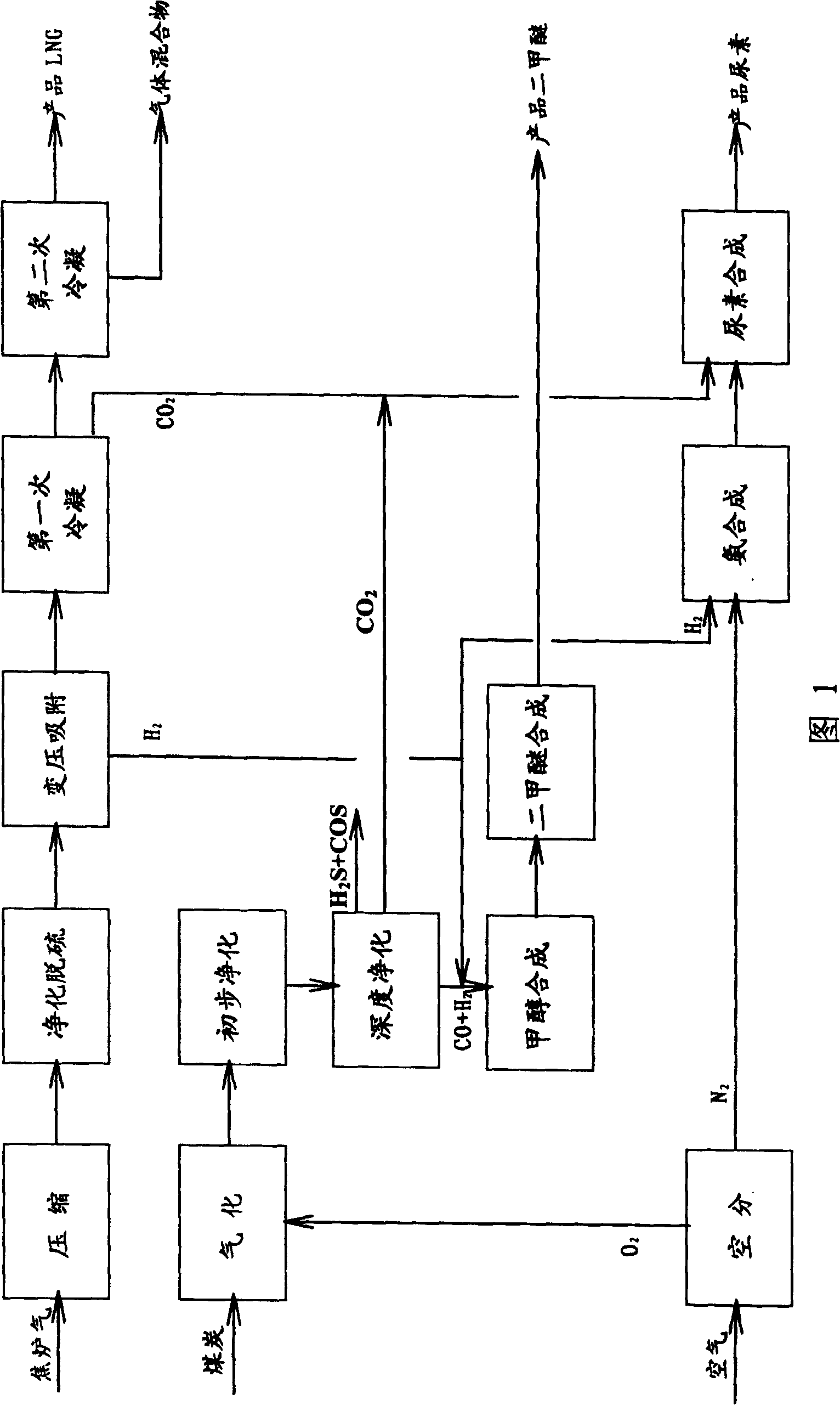

Method for concurrently producing dimethyl ether, liquefied natural gas and urea

A technology for liquefied natural gas and dimethyl ether, applied in chemical instruments and methods, preparation of organic compounds, preparation of ether, etc., can solve problems such as emission loss and waste of coal resources, and achieve the effects of saving investment, realizing economy, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the process of coal gasification, the coal is pre-treated and sprayed into the ash fusion gasification furnace at a temperature of 1000 ° C and a pressure of 1.0 MPa to chemically react with water vapor and pure oxygen from air separation to generate CO, H 2 , CO 2、H 2 O and a small amount of CH 4 、H 2 Water gas with S, COS and other components. The water gas containing a small amount of dust and impurities is initially purified. Due to the dusty water gas from gasification, it still contains acid gas after being washed, dedusted and cooled by Venturi scrubber and carbon scrubber. In order to protect the compressor, desulfurization by tannin extract method is also used. Make H 2 S content is less than 30mg / Nm 3 , the pre-purified water gas is compressed to a pressure of 5.7MPa, and then deeply purified. Deep purification adopts polyethylene glycol dimethyl ether (NHD) method for desulfurization and decarburization. Removed H 2 S gas desulfurization recovery...

Embodiment 2

[0038] In the coal gasification process, the coal is pre-treated to make 65% coal-water slurry and sprayed into the Texaco gasifier at a temperature of 1450°C and a pressure of 6.5Mpa to form pure oxygen with gasified water vapor and air separation. Carry out a chemical reaction to produce CO, H 2 , CO 2 、H 2 O and a small amount of CH 4 、H 2 Water gas with S, COS and other components. The gasified dusty water gas, after being washed, dedusted and cooled by Venturi scrubber and carbon washing tower, enters deep purification, in which low-temperature methanol washing process is used for desulfurization and decarbonization. Removed H 2 S gas desulfurization recovery unit recovers sulfur and removes CO 2 To urea synthesis. The purified water gas is mixed with the hydrogen gas compressed to 5.7MPa pressure produced by pressure swing adsorption of coke oven gas to form methanol synthesis gas, H 2 S content≤0.1ppm, hydrogen-to-carbon ratio mole=(H 2 -CO 2 ) / (CO+CO 2 )=2.0...

Embodiment 3

[0043] In the coal gasification process, the coal is pre-treated to make 65% coal-water slurry and sprayed into the Texaco gasifier at a temperature of 1450 ° C and a pressure of 6.0 MPa to form pure oxygen with gasified water vapor and air separation. Carry out a chemical reaction to produce CO, H 2 , CO 2 、H 2 O and a small amount of CH 4 、H 2 Water gas with S, COS and other components. The gasified dusty water gas, after being washed, dedusted and cooled by Venturi scrubber and carbon washing tower, enters deep purification, in which low-temperature methanol washing process is used for desulfurization and decarbonization. Removed H 2 S gas desulfurization recovery unit recovers sulfur and removes CO 2 To urea synthesis. The purified water gas is mixed with hydrogen gas compressed to 5.2MPa pressure produced by pressure swing adsorption of coke oven gas to form methanol synthesis gas, H 2 S content≤0.1ppm, hydrogen-to-carbon ratio mole=(H 2 -CO 2 ) / (CO+CO 2 )=2.09...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com