Fuel cell stack

A fuel cell stack and current technology, applied in the direction of fuel cells, fuel cell groups, fuel cell components, etc., can solve the problems of easy corrosion of bolts and easy contamination of fuel, and achieve simple structure, wide adaptability, and volume The effect of high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

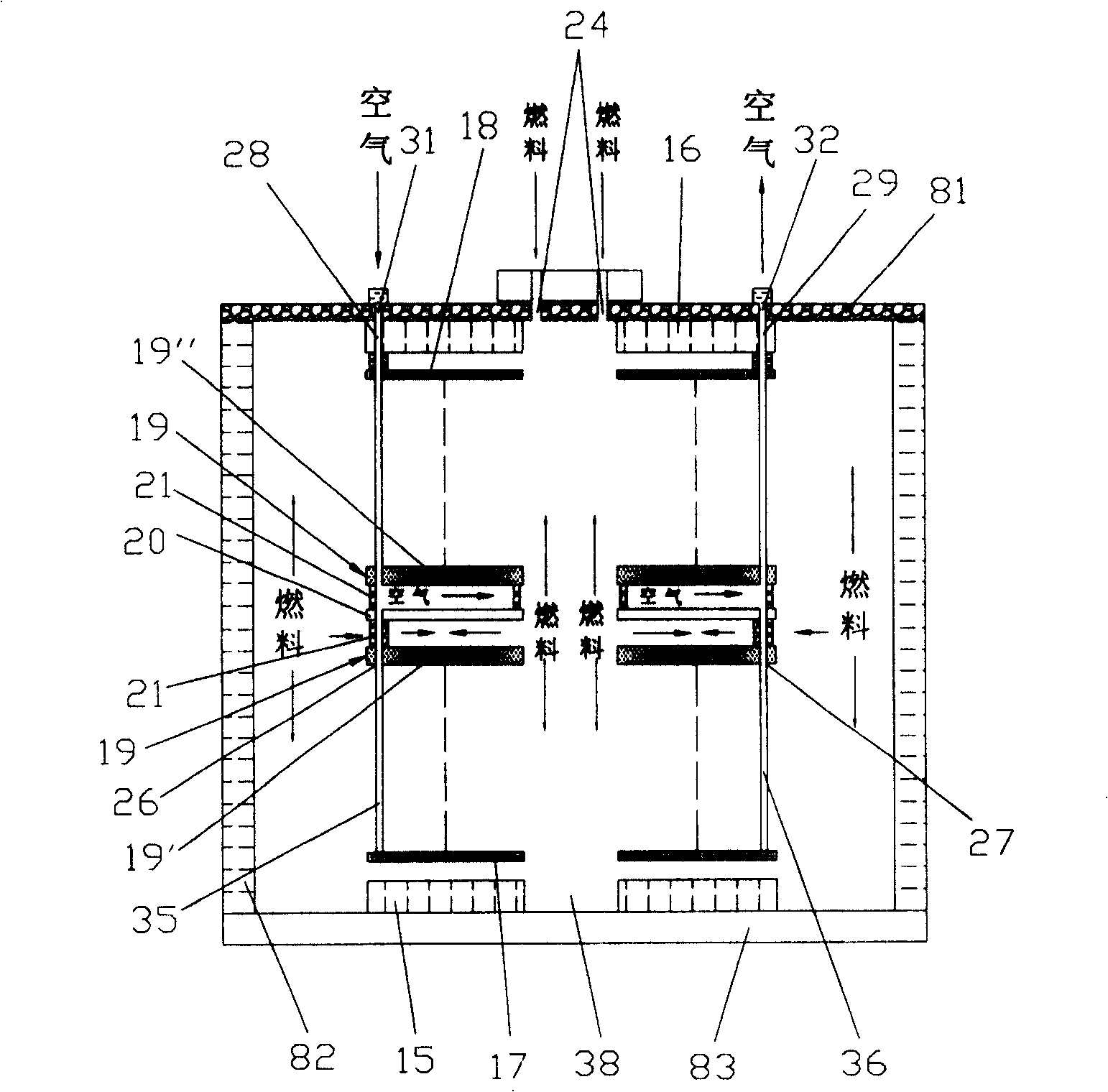

[0032] The present invention will be further described below in conjunction with the drawings and specific embodiments.

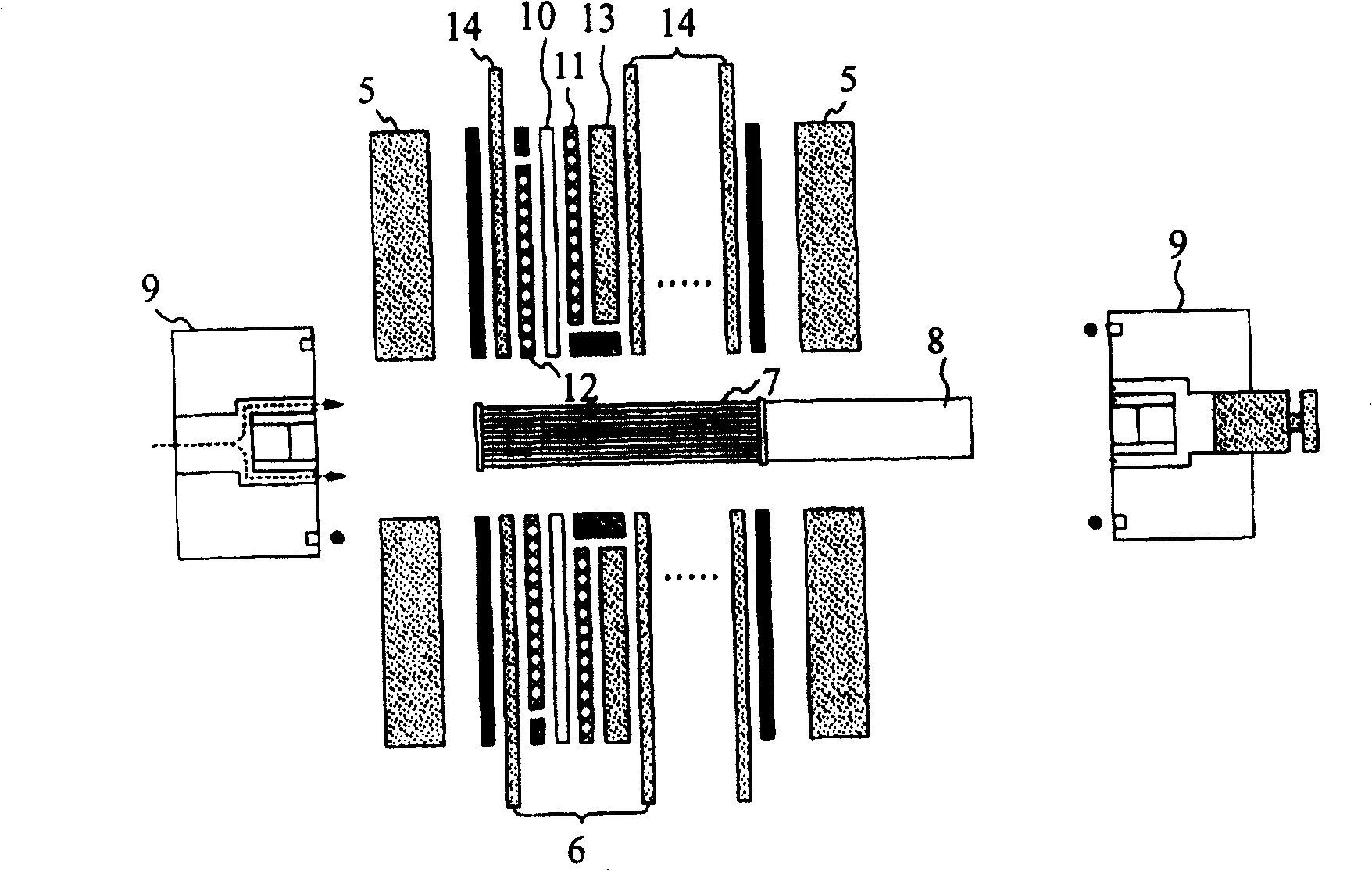

[0033] The fuel cell stack provided by the present invention includes a first end plate 15, a second end plate 16, a first current guide plate 17, a second current guide plate 18, a plurality of electrode plates 19, a plurality of membrane electrodes 20 and a sealing gasket 21. And the fuel cell stack also includes a fixing device.

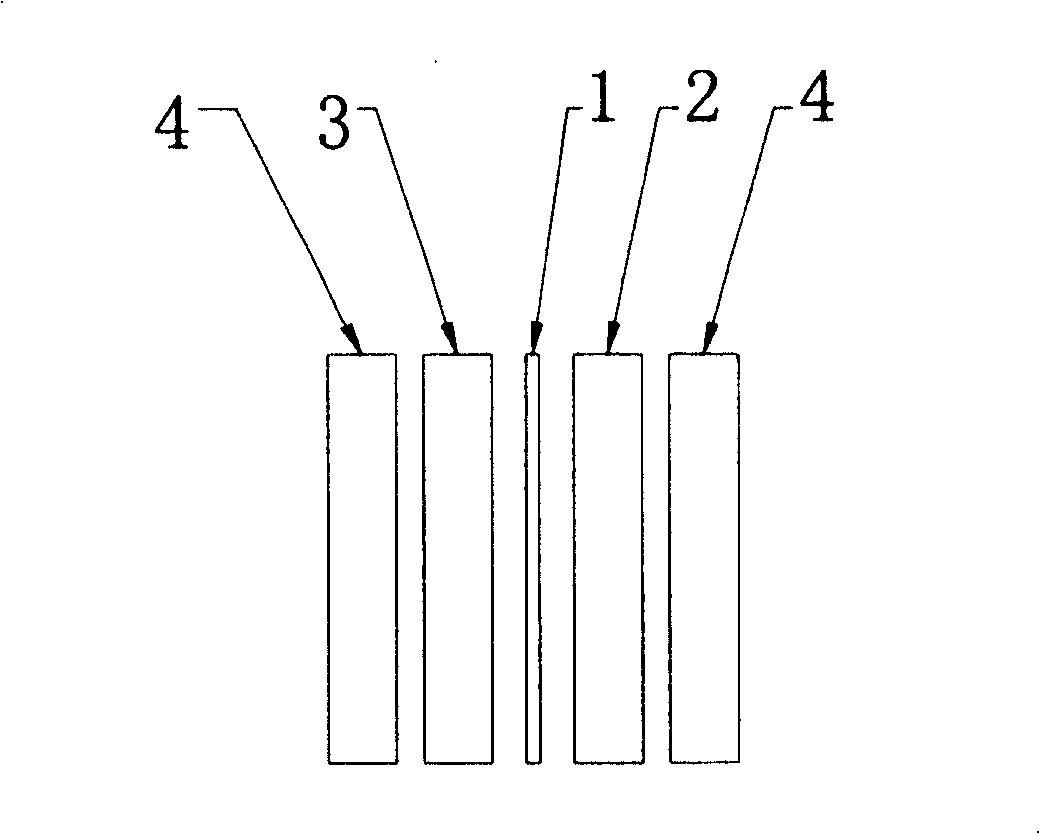

[0034] Wherein, the electrode plate 19 may be a plate, which includes a front face 19' and a back face 19"; or the electrode plate 19 may also include two closely-fitting first flow field plates 19' and second flow field plates 19 ". When the pole plate 19 is a plate, the shape, structure and function of the front face 19' of the pole plate 19 are equivalent to that of the first flow field plate 19' when the pole plate 19 includes two flow field plates. The shape, structure and function of the surface to which the plate 19" fits; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com