Structure of active carbon fibrous adsorptive bed with static charge reinforcing control

A technology of activated carbon fiber and activated carbon fiber cloth, which is applied in the field of high power density adsorption beds and can solve problems such as rising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

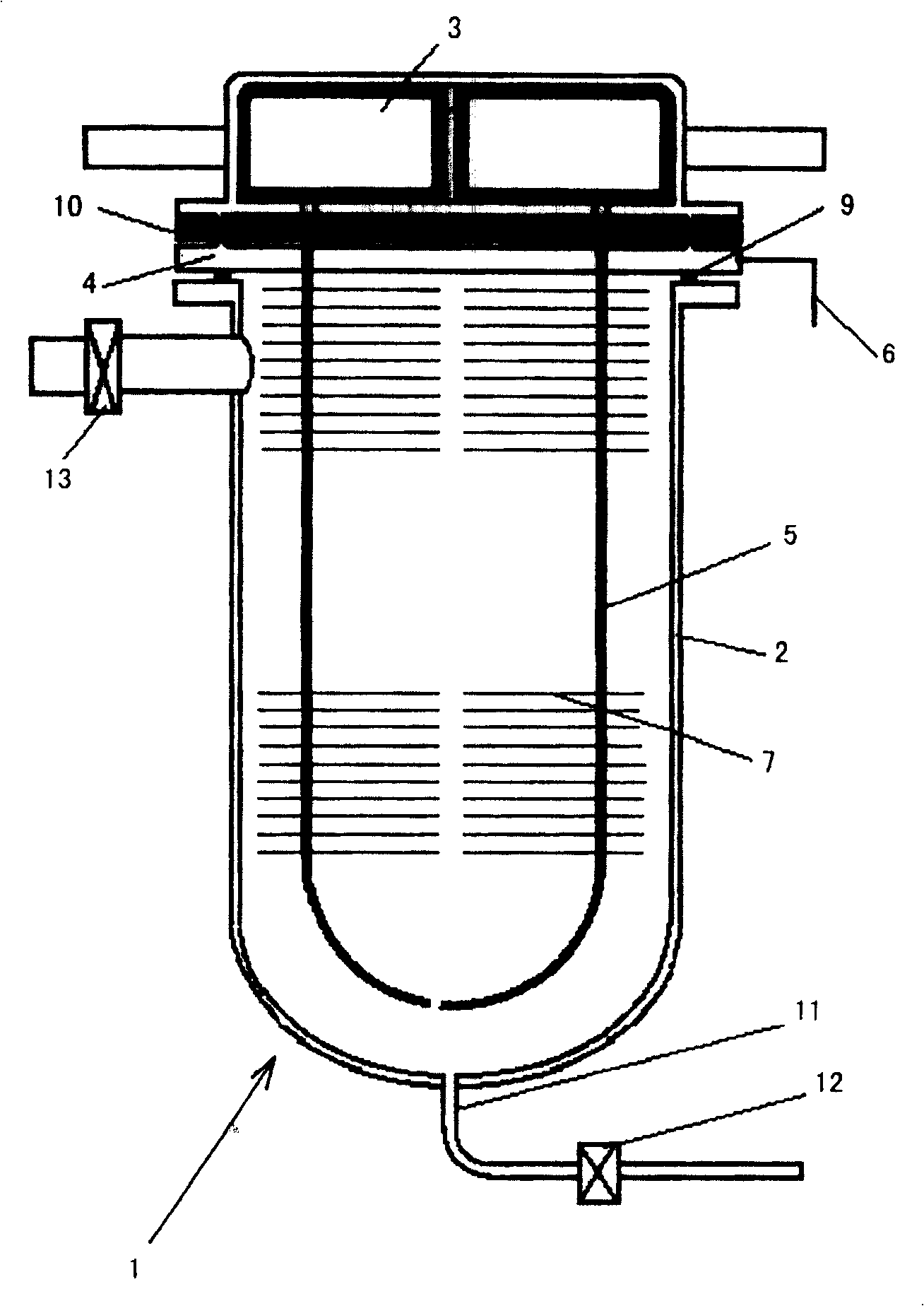

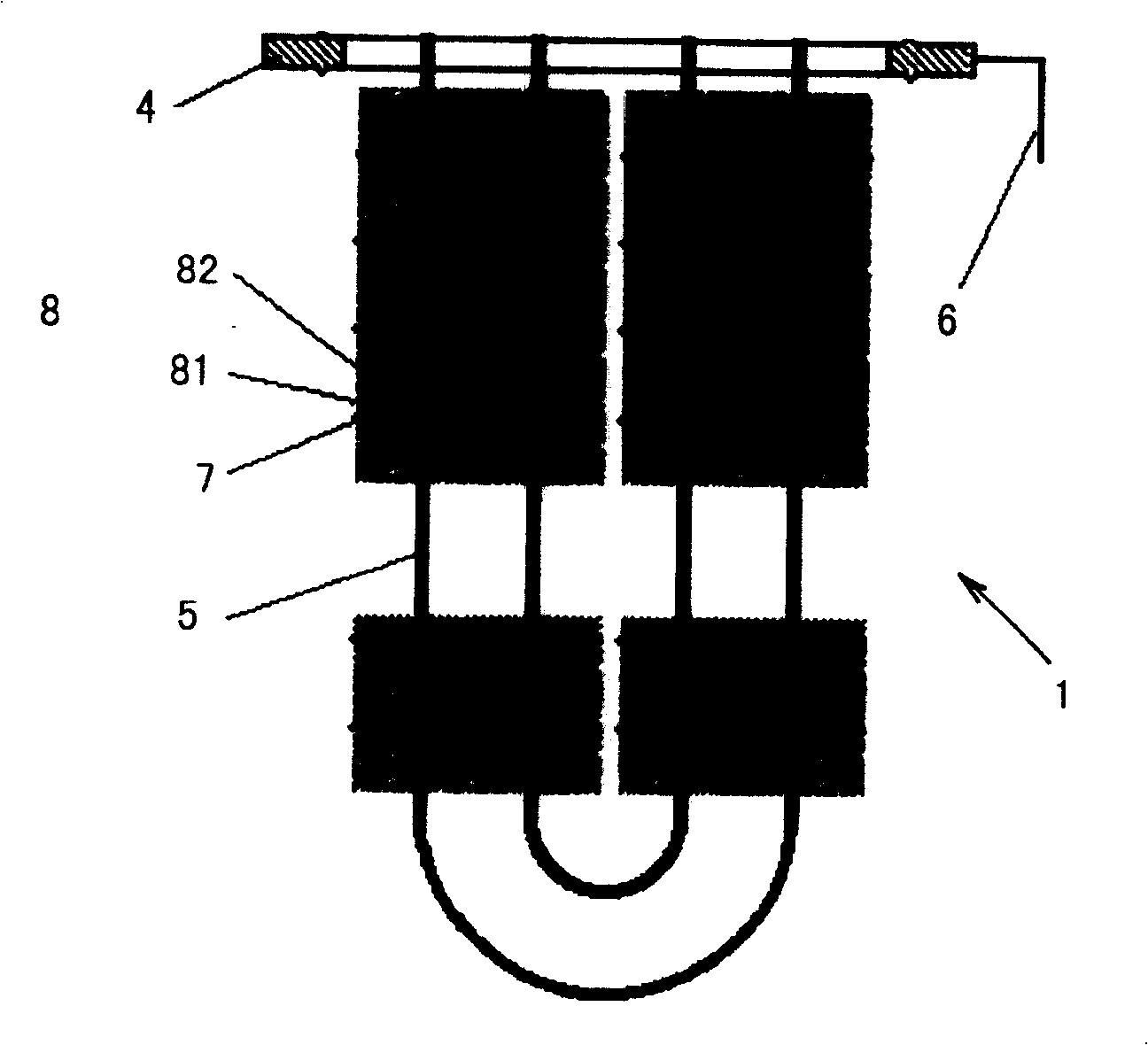

[0020] In order to further describe the structural features and functions of the present invention, the following description is given in conjunction with the accompanying drawings:

[0021] See figure 1 , The core end plate 4, the metal U-shaped tube 5, the electrostatic input end 6, the aluminum fin 7 and the attachments 8 on the fin constitute the adsorbent bed core 1. The core 1 is made of polytetrafluoroethylene or fluororubber material and the shell The body 2 and the head 3 are electrostatically insulated, and the input or discharge of static charge to the core 1 can only be done through the electrostatic input terminal 6. The polytetrafluoroethylene or fluororubber material includes an electrostatic insulating sealing ring 9 and an electrostatic insulating plate 10. The electrostatic insulating sealing ring 9 is placed between the shell 2 and the core end plate 4, on the lower surface of the core end plate 4, and the shell The open periphery of the body 2 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com