Jumper wire connector suitable for six class standard

A technology for connecting components and jumpers, which is applied in the direction of needle points/slotted plate contacts, electrical components, etc. used to connect and penetrate insulated wires/cable core wires, which can solve the problem that the jumper connector has too much interference and cannot be constructed. On-site operation and connection method cannot break through the problems of RJ-45 type connector jumper connection method, etc., to achieve the effect of improving return loss, eliminating wiring tools and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

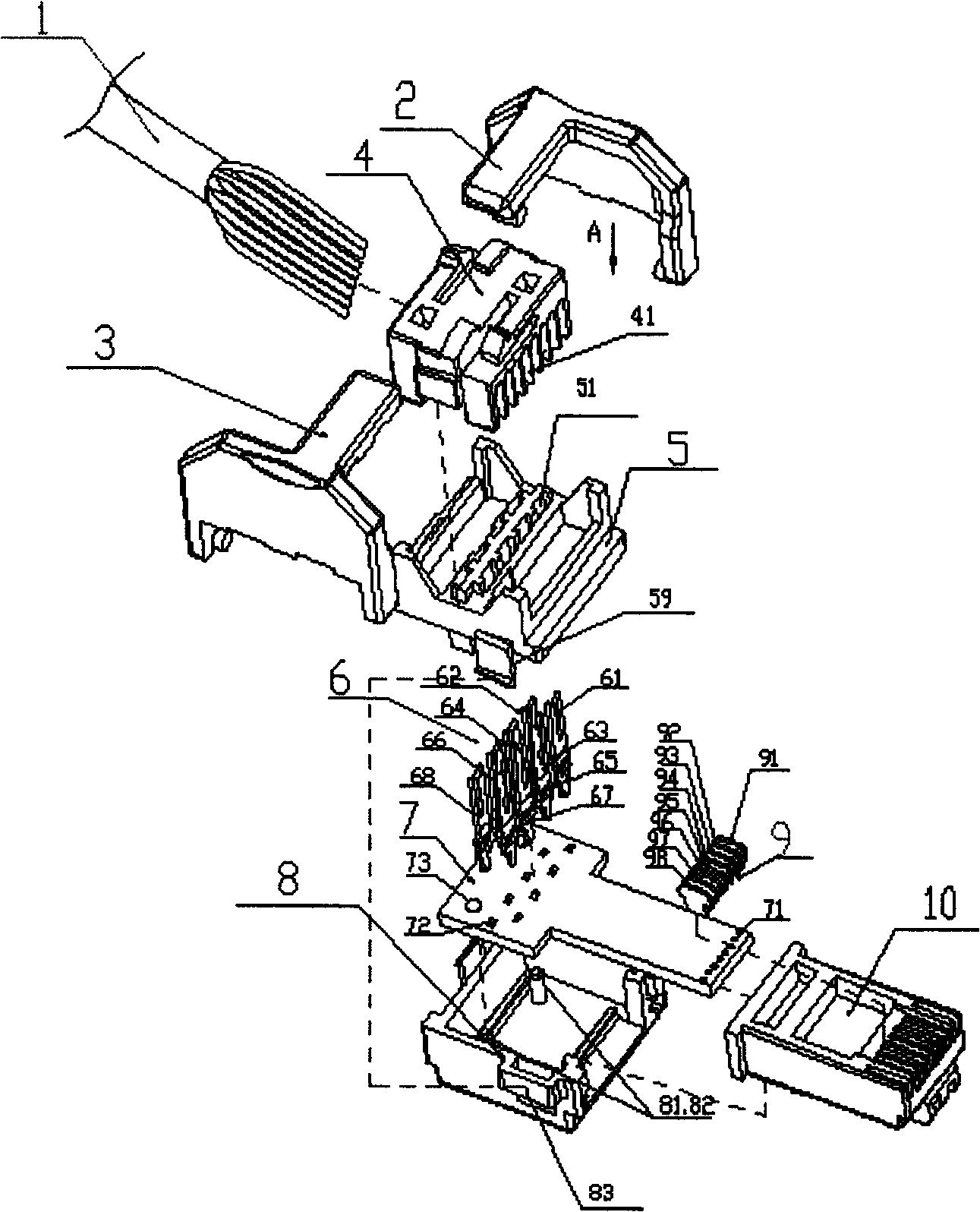

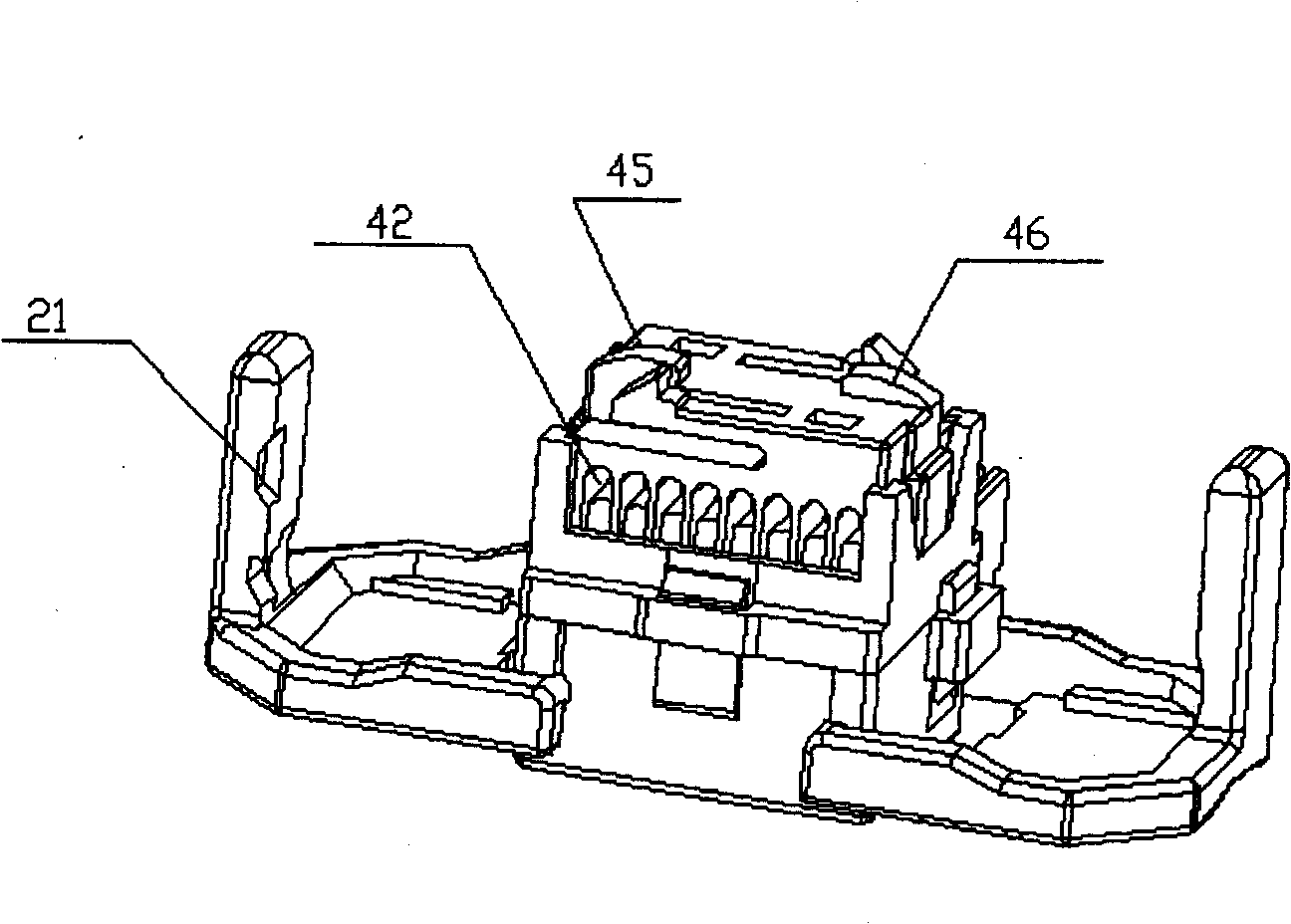

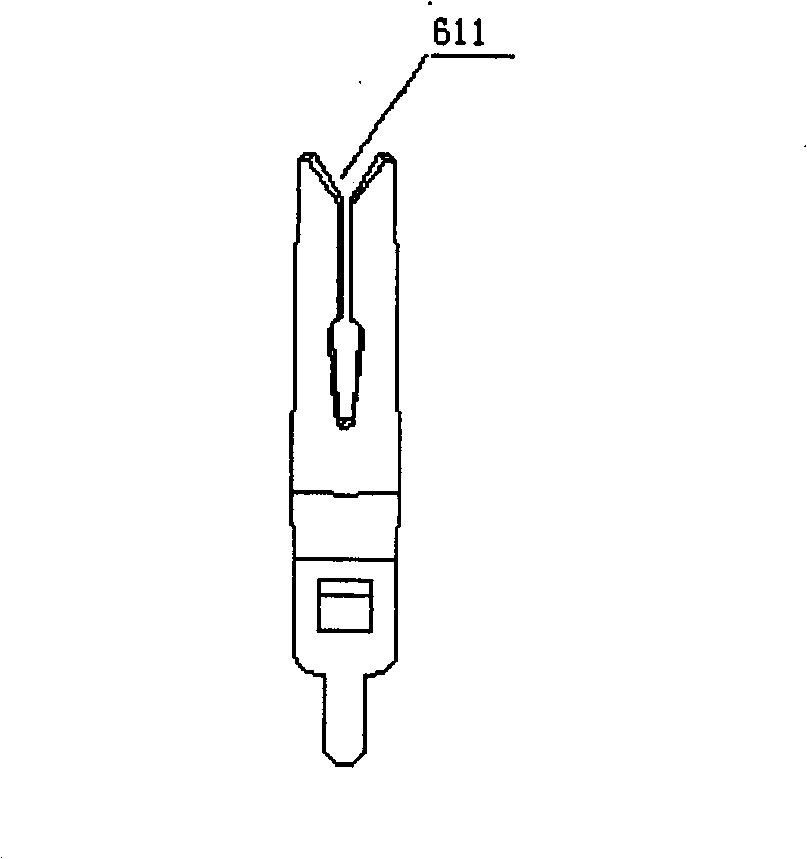

[0018] The structure of the jumper connection assembly applicable to six types of standards of the present invention will be described below with reference to the accompanying drawings.

[0019] figure 1 It is a structural schematic diagram of the jumper connection assembly applicable to six types of standards of the present invention, figure 2 It is a schematic diagram illustrating the structure of the locator and the booster part of the jumper connection assembly applicable to the six types of standards of the present invention, image 3 It is a schematic diagram illustrating the structure of the electric conductor part of the jumper connection assembly applicable to the six types of standards of the present invention, Figure 4 It is a schematic diagram illustrating the circuit board routing mode of the jumper connection assembly applicable to six types of standards of the present invention.

[0020] The jumper connection assembly applicable to the six types of standards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com