Automatic stop centering mechanism in use for reciprocating pump

An automatic centering and reciprocating pump technology, used in machines/engines, liquid fuel engines, pump components, etc., can solve the problems of poor reliability, eccentric wear of the plunger, and poor alignment, and achieve high reliability and avoid deviation. Grinding and reducing the effect of pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

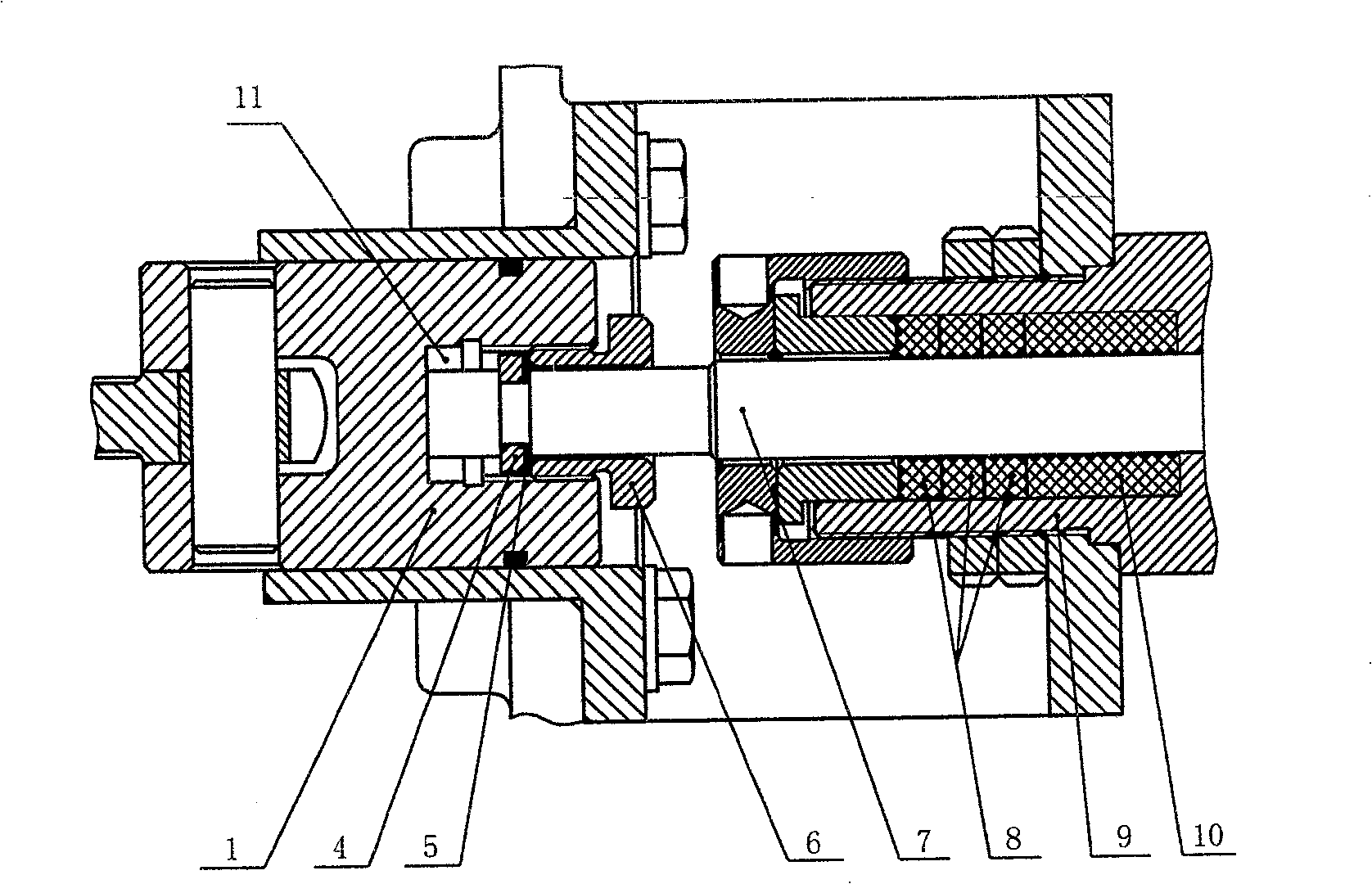

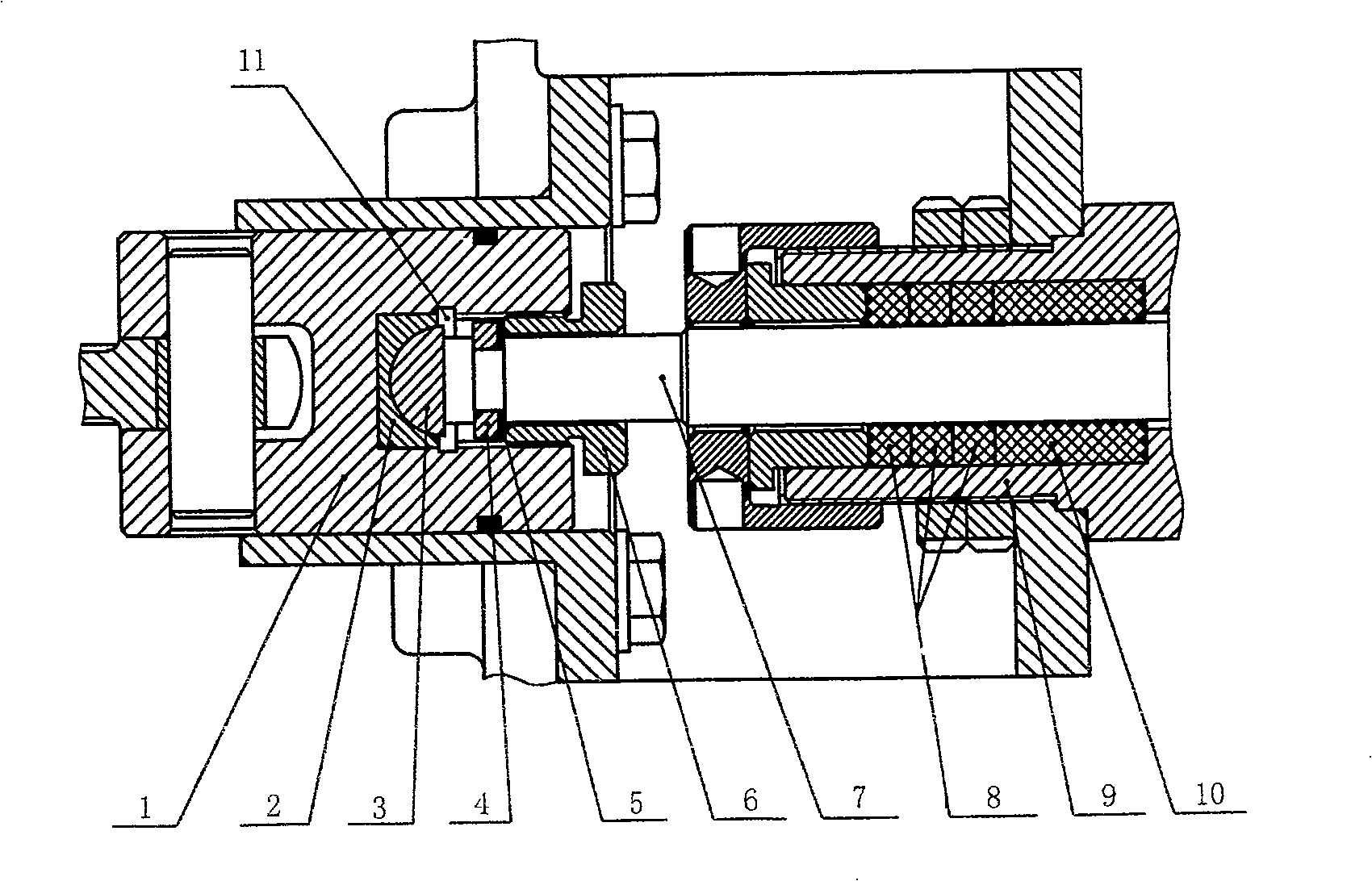

[0016] refer to figure 2 , a plunger automatic centering mechanism for a reciprocating pump, comprising a crosshead (1) and a plunger (7) connected to a reciprocating drive mechanism, one end of the plunger (7) is installed on the crosshead ( 1) In the plunger cavity (11), the other end of the plunger (7) passes through the stuffing (8) and the guide sleeve (10), and the stuffing (8) and the guide sleeve (10) are installed in the stuffing box (9); The end of the plunger (7) is connected to the crosshead (1) through a spherical sliding assembly; the spherical sliding assembly is composed of a spherical seat (2) and a hemisphere (3), and the bottom of the plunger cavity (11) is installed with the spherical seat (2), the hemisphere (3) is located in the spherical surface of the spherical seat (2), and the hemisphere (3) is fixedly connected to the end of the plunger (7)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com