System and method for central heating using heat pump technical principle and its relative equipment

A central heating and heat pump technology, applied in hot water central heating systems, heating systems, household heating, etc., can solve problems such as heat energy can not be recycled, achieve the goal of reducing redundant construction, saving investment, and improving heating capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

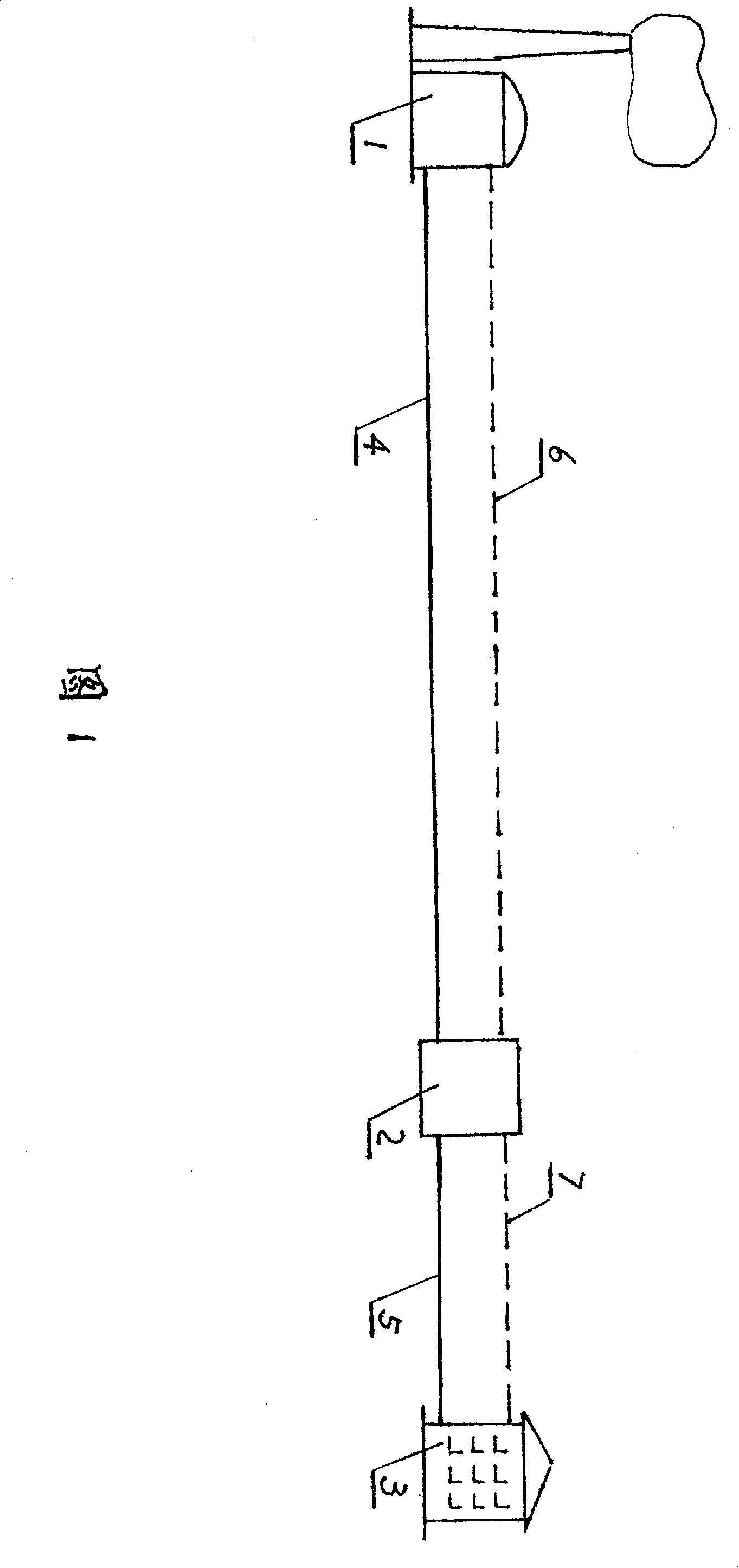

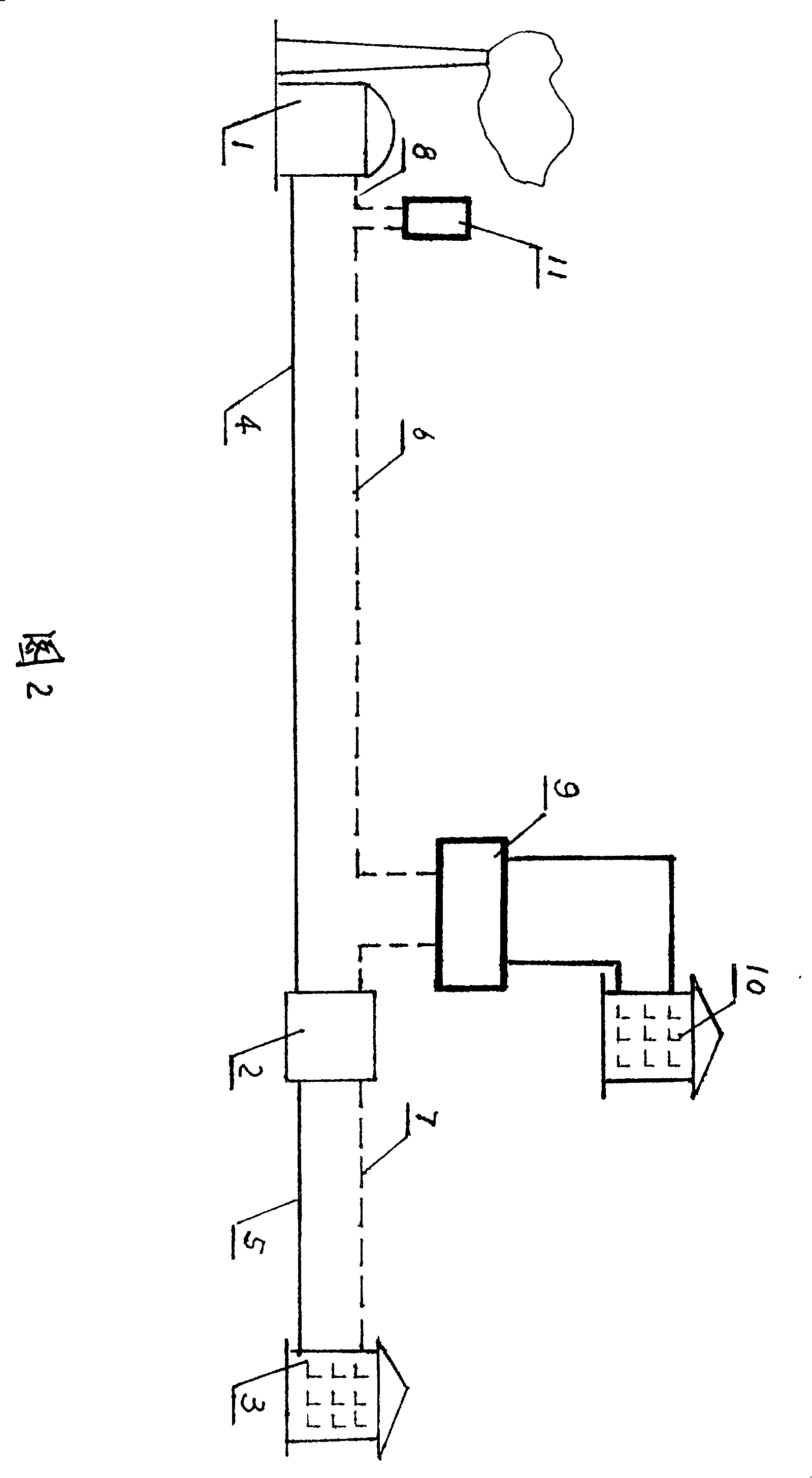

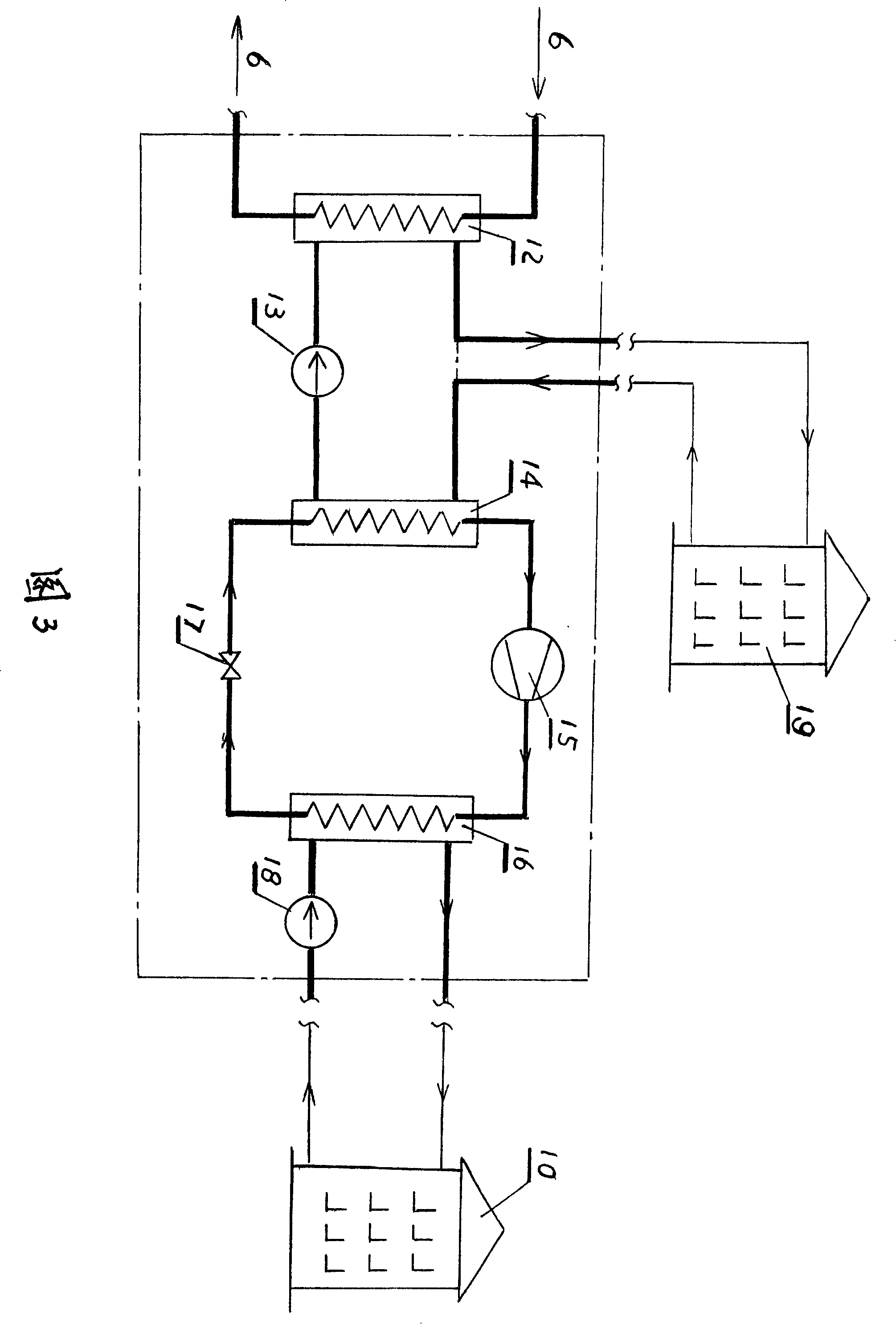

[0028] In the figure 1. Thermal power plant or regional boiler room, 2. Heating station, 3. Heat user, 4. Primary pipe network water supply pipe, 5. Secondary pipe network water supply pipe, 6. Primary pipe network return water pipe, 7. Secondary pipe network return pipe, 8. Primary pipe network return pipe, 9. Heat pump heating device, 10. Heat user, 11. Heat pump preheating device, 12. Heat exchanger, 13. Circulation pump, 14. Evaporator, 15, compressor, 16, condenser, 17, expansion regulating valve, 18, circulation pump, 19, heat user, 20, heat exchanger, 21, circulation pump, 22, evaporator, 23, compressor, 24. Condenser, 25. Expansion regulating valve, 26. Low temperature water source pipeline.

[0029] In the hot water centralized heating engineering system shown in Figure 1, the primary heat supply cycle network is mainly composed of a thermal power plant or a regional boiler room 1, a heating station 2, a heat user 3, a water supply pipeline 4 and a return water pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com