Technique for removing CO2 from flue-gas

A technology of carbon dioxide and process methods, applied in chemical instruments and methods, separation methods, chemical separation, etc., can solve problems such as low partial pressure of carbon dioxide, explosion, slow reaction rate, etc., to increase solubility, improve removal efficiency, and avoid The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

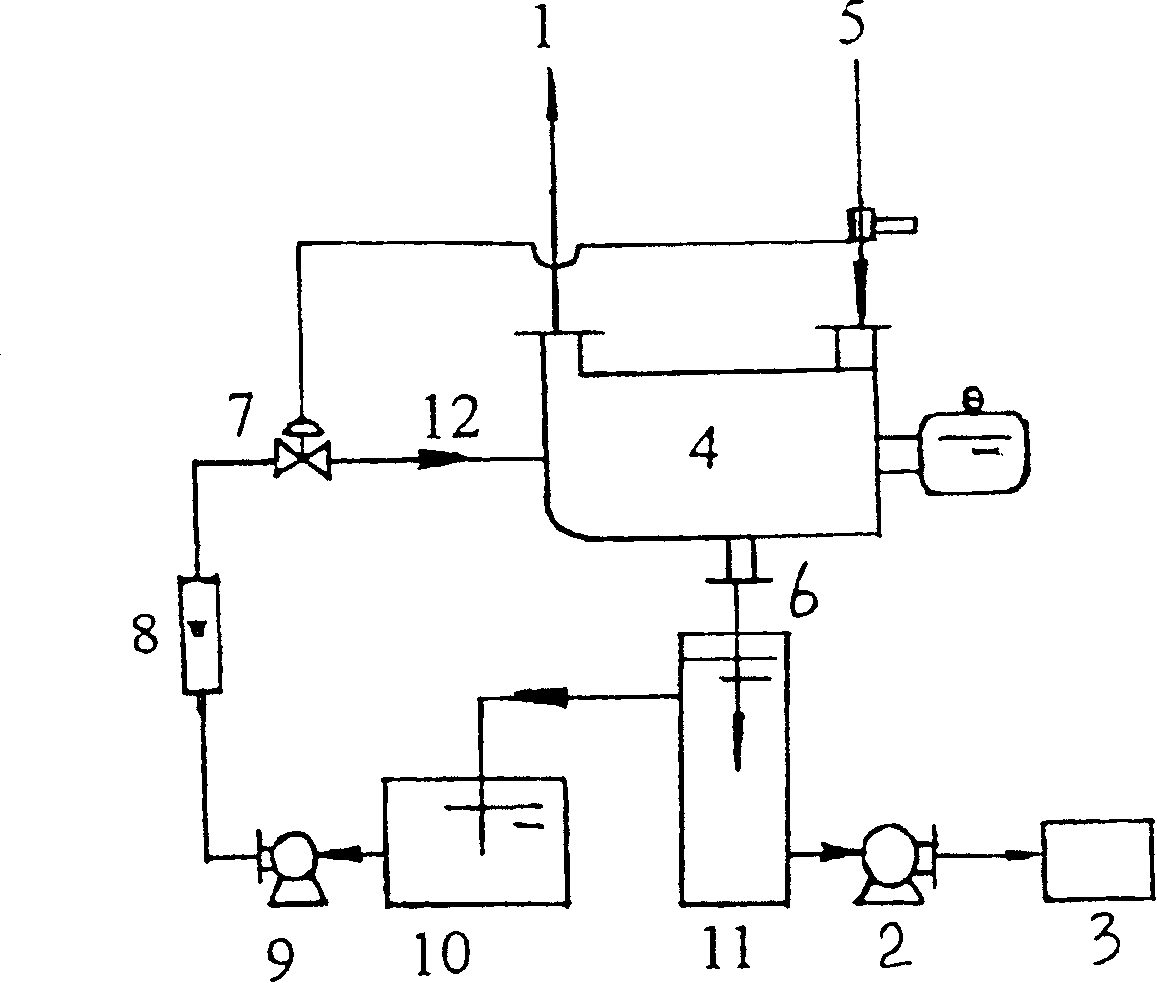

[0025] A process for removing carbon dioxide in flue gas comprises the following process steps:

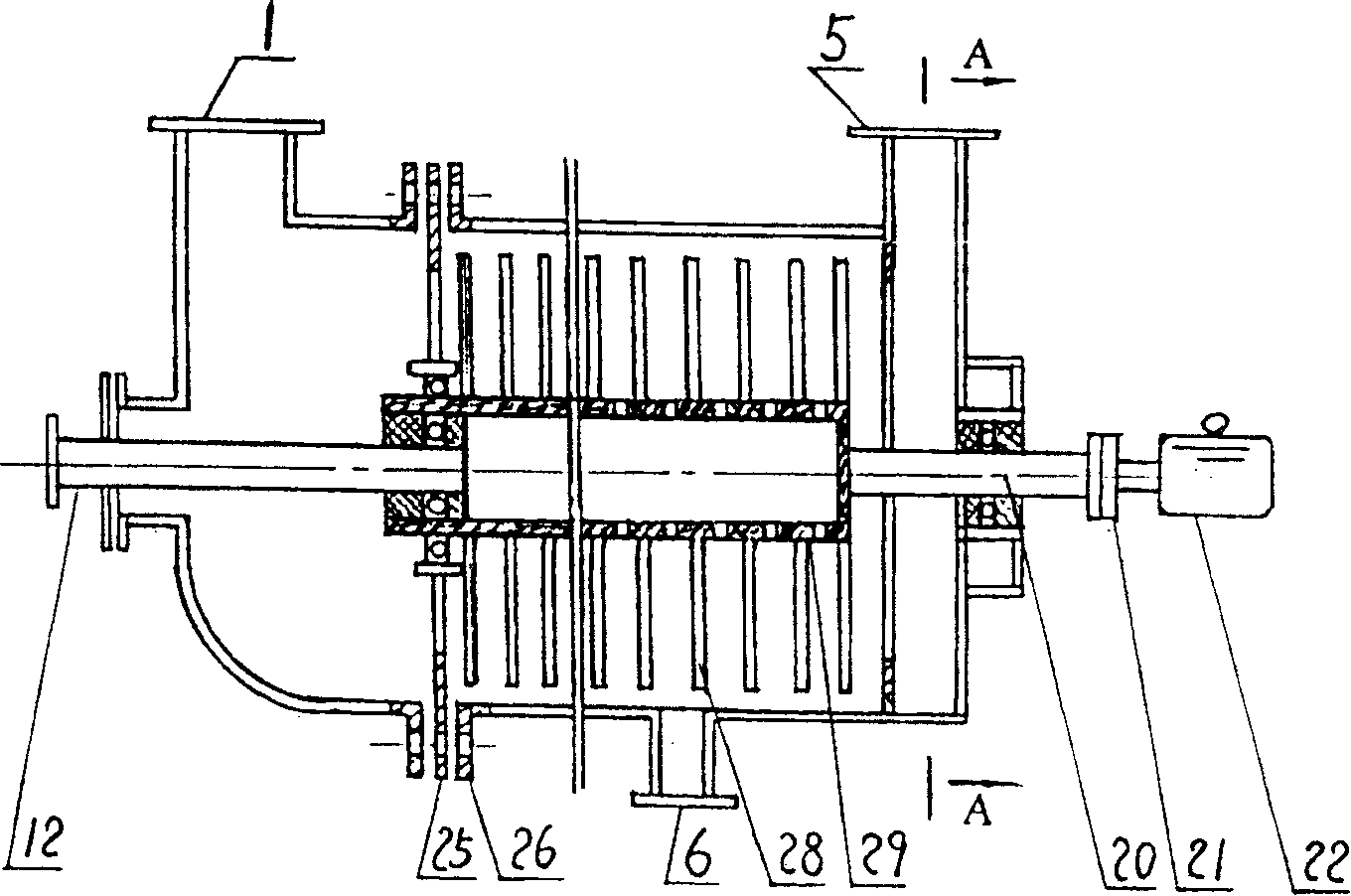

[0026] A, the flue gas containing carbon dioxide is sent into the smoke inlet end of the absorption reactor 4 along the tangential direction, so that it flows from the smoke inlet 5 end to the gas outlet 1 end;

[0027] B. Simultaneously, spray ammonia water with a concentration of 8% from the through hole on the central shaft in the axial middle, and spray it into the absorption reactor 4 from the inside to the outside in the radial direction, so that the gas and liquid two-phase cross-flow contact reaction;

[0028] C, the liquid after the reaction flows into the airtight intermediate storage tank 11 from the drain port 6 at the bottom of the absorption reactor 4, and the solid matter generated is deposited at the bottom of the intermediate storage tank 11, and the supernatant of the intermediate storage tank 11 overflows into the ammonia water tank 10 ;

[0029] D, add an appr...

Embodiment 2

[0038] Adjust the ammonia concentration in the ammonia tank 10 to be 10%. Other technological process is with embodiment 1.

Embodiment 3

[0040] Adjust the ammonia concentration in the ammonia tank 10 to be 16%, and the other processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com